TOPCon battery main grid silver paste and preparation method thereof

A silver paste and battery technology, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as difficult welding, and achieve uniform collection, good compactness and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

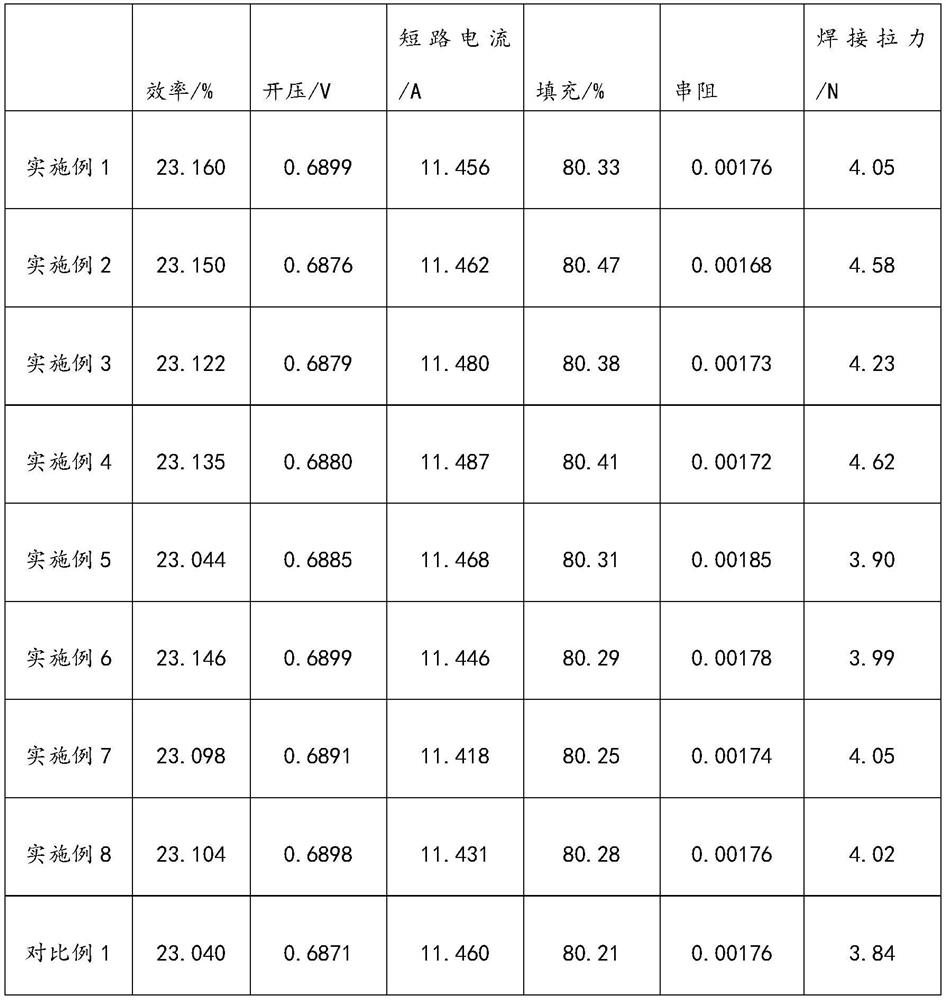

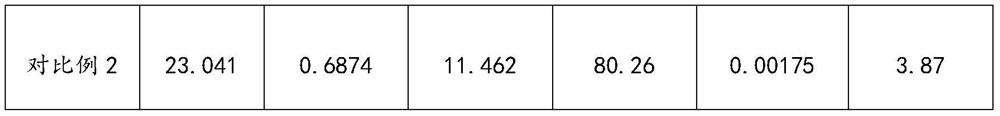

Examples

Embodiment 1

[0040] A kind of TOPCon battery main grid electrode silver paste, its mass percentage is composed as follows: 83.5% mixed silver powder, 1.5% main glass powder, 0.4% auxiliary glass powder, 12.4% organic vehicle, 1.5% thixotropic agent, 0.4% dispersant, 0.1% emulsifier, 0.1% defoamer, 0.1% leveling agent.

[0041] The preparation method is as follows:

[0042] (1) Preparation of mixed silver powder, take by weight 92% spherical silver powder A, 5% quasi-spherical silver powder B, 3% nano silver powder C and mix by mass percentage; the median diameter of the spherical silver powder A is 1.25 μm , the tap density is 5.6g / cm 3 ; The median particle size of the spherical silver powder B is 1.78 μm, and the tap density is 5.8 g / cm 3 ; The median diameter of the nano-silver powder C is 0.8 μm, and the tap density is 4.6g / cm3; the density of the mixed silver powder after sintering is 7.8g / cm 3 ;

[0043] (2) The main glass powder is calculated according to the mole percentage and...

Embodiment 2

[0047] The mass percent composition of the busbar silver paste in this embodiment is as follows: 82% mixed silver powder, 1.5% main glass powder, 0.4% auxiliary glass powder, 14% organic vehicle, 1.4% thixotropic agent, 0.4% dispersant Agent, 0.1% emulsifier, 0.1% defoamer, 0.1% leveling agent.

[0048] The preparation method is as follows:

[0049] (1) the preparation of mixed silver powder, take by mass percentage 8% spherical silver powder A, 90% quasi-spherical silver powder B, 2% nanometer silver powder C and mix; The median diameter of described spherical silver powder A is 1.1 μ m, the tap density is 5.8g / cm 3 ; The median particle size of the spherical silver powder B is 1.5 μm, and the tap density is 6.1 g / cm 3 ; The median diameter of the nano-silver powder C is 0.75 μm, and the tap density is 4.8 g / cm 3 ;The density of mixed silver powder after sintering is 8.0g / cm 3 ;

[0050] (2) The composition and preparation of main glass powder and auxiliary glass powder ...

Embodiment 3

[0054] The mass percent composition of the busbar silver paste in this embodiment is as follows: 83.5% mixed silver powder, 1.8% main glass powder, 0.5% auxiliary glass powder, 11.8% organic vehicle, 1.7% thixotropic agent, 0.4% dispersant Agent, 0.1% emulsifier, 0.1% defoamer, 0.1% leveling agent.

[0055] The preparation method is as follows:

[0056] (1) the preparation of mixing silver powder is identical with embodiment 1;

[0057] (2) The main glass powder is calculated according to the mole percentage and the components are as follows: PbO 28mol%, SiO 2 36mol%, TiO 2 20mol%, ZnO 7mol%, TeO 2 5mol%, Bi 2 o 3 4mol%; Auxiliary glass powder is calculated according to mole percent and is as follows: Bi 2 o 3 19mol%, SiO 2 52mol%, CuO 14mol%, MnO 2 6mol%, TeO 2 4mol%, ZnO 3mol%, MoO 3 2mol%; each component of the main glass powder and the auxiliary glass powder is mixed uniformly in the mixer, and then heated in a high-temperature furnace to 1600 ° C, kept ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com