Holding head telescopic structure of car lifting jack

A telescoping structure and crane technology, which is applied in the field of cranes, can solve problems such as unsafe hidden dangers, accidents, and impact on safe production, and achieve the effects of convenient adjustment and fixation, wide application range, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

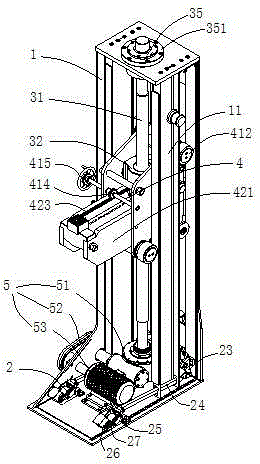

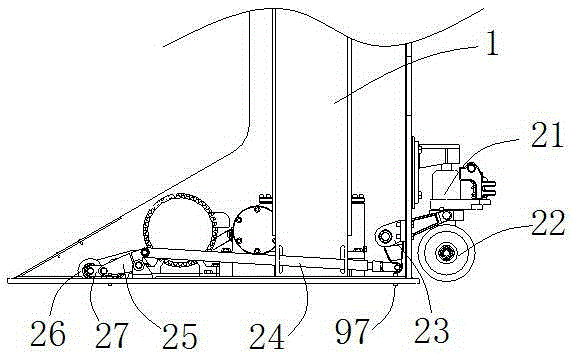

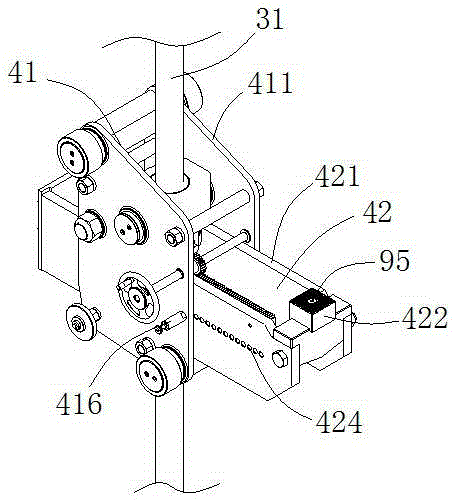

[0022] The present invention will be described in further detail below in conjunction with a kind of trolley machine system adopting this new type of use and accompanying drawings.

[0023] During specific implementation: if Figure 1~Figure 9 As shown, a crane system includes a crane unit including at least four mobile cranes and a PLC system 9 for controlling the synchronous lifting of the crane units. The mobile crane includes a vertical The set body 1, the walking mechanism 2 arranged at the bottom of the body 1 that can adjust the ground clearance of the body 1, the bracket mechanism 4 that can move up and down along the body 1 for lifting the car body, and vertically arranged in the body 1 A lead screw 31, the lead screw 31 is equipped with a work nut 32, the work nut 32 is fixedly connected to the bracket mechanism 4; the upper end of the lead screw 31 is rotatably hung on the The top plate of the body 1; the bottom plate of the body 1 is provided with a drive device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com