Method for preparing high-purity strontium dihydroxide by utilizing strontium slag

A technology of strontium hydroxide and sodium hydroxide, applied in calcium/strontium/barium oxide/hydroxide, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve environmental problems such as pollution, waste of resources, etc. To achieve the effect of short process flow, reduce pollution and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

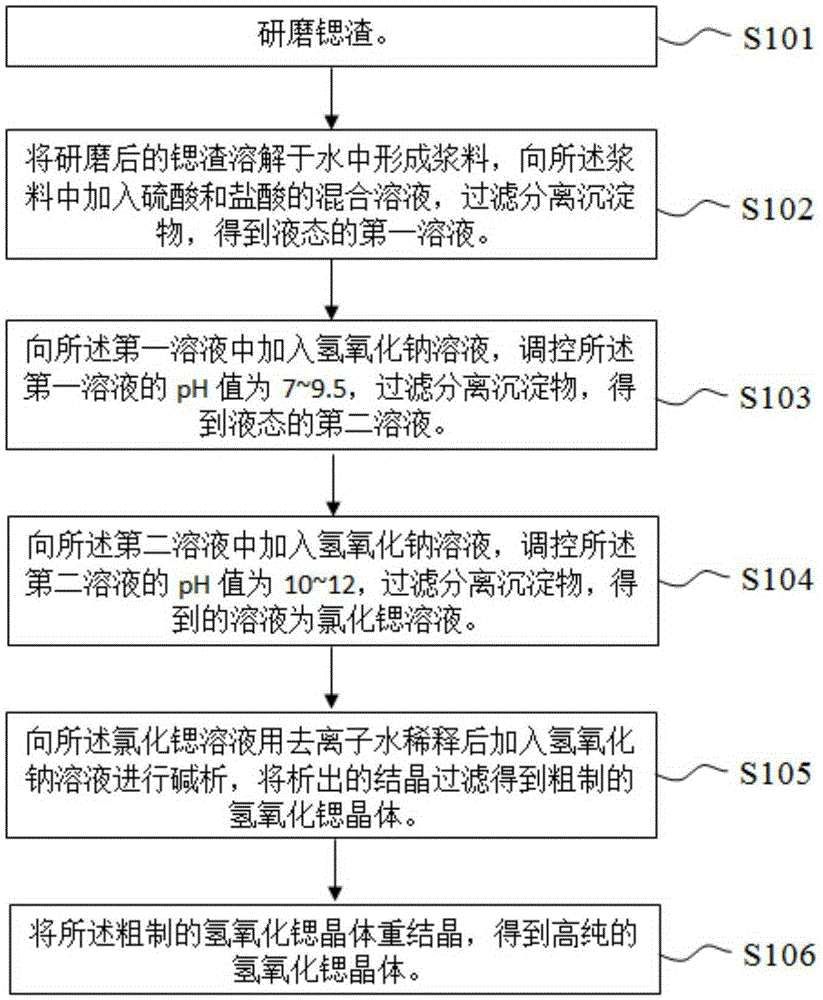

[0032] 1. Grinding the strontium slag. The smaller the particle size, the better.

[0033] 2. Mix the ground strontium slag and water according to the mass ratio of 1:1 to form a slurry, add a mixed solution of sulfuric acid and hydrochloric acid to the slurry, wherein the mass percent concentration of sulfuric acid is 0.5% to 1%, and the concentration of hydrochloric acid The mass percent concentration is 15% to 20%, the pH of the solution is adjusted to 0 to 0.2, heated to 85° C. and then kept at the temperature for 1 hour, and then the precipitate is separated by filtration to obtain the first liquid solution.

[0034] 3. Add 15% sodium hydroxide solution to the first solution, adjust the pH value of the first solution to 7, heat to 70° C. and keep the temperature for 1 hour, then filter and separate the precipitate to obtain a liquid second solution.

[0035] 4. Add a sodium hydroxide solution with a mass concentration of 15% to the second solution, adjust the pH value of...

Embodiment 2

[0040] 1. Grinding the strontium slag. The smaller the particle size, the better.

[0041] 2. Mix the ground strontium slag and water according to the mass ratio of 1:2 to form a slurry, add a mixed solution of sulfuric acid and hydrochloric acid to the slurry, wherein the mass percent concentration of sulfuric acid is 0.5% to 1%, and the concentration of hydrochloric acid The mass percent concentration is 15% to 20%, the pH of the solution is adjusted to 0 to 0.2, heated to 90° C. and then kept at a constant temperature for 2 hours, and then the precipitate is filtered to obtain a liquid first solution.

[0042] 3. Add 18% sodium hydroxide solution to the first solution, adjust the pH value of the first solution to 8, heat to 50° C., keep the temperature for 2 hours, and then filter and separate the precipitate to obtain a liquid second solution.

[0043] 4. Add a sodium hydroxide solution with a mass concentration of 18% to the second solution, adjust the pH value of the se...

Embodiment 3

[0048] 1. Grinding strontium slag. The smaller the particle size, the better.

[0049] 2. Mix the ground strontium slag and water according to the mass ratio of 1:3 to form a slurry, and add a mixed solution of sulfuric acid and hydrochloric acid to the slurry, wherein the mass percentage concentration of sulfuric acid is 0.5% to 1%, and the mass percentage of hydrochloric acid The percentage concentration is 15%-20%, the pH of the solution is adjusted to 0-0.2, then the mixed solution is heated to 100° C. and then kept at a constant temperature for 1.5 hours; finally cooled, filtered, and the precipitate is separated to obtain the first liquid solution.

[0050] 3. Add 20% sodium hydroxide solution to the first solution, adjust the pH value of the first solution to 9.5, heat to 60°C and keep the temperature for 0.5h, then filter and separate the precipitate to obtain a liquid second solution.

[0051] 4. Adding a sodium hydroxide solution with a mass concentration of 20% to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com