Arch bridge inspection car track device

A technology for inspecting cars and tracks, applied to bridges, bridge parts, bridge construction, etc., can solve problems affecting the safety of steel truss arch bridges, damage to steel truss arches, etc., and achieve the effects of simple structure, low production cost, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

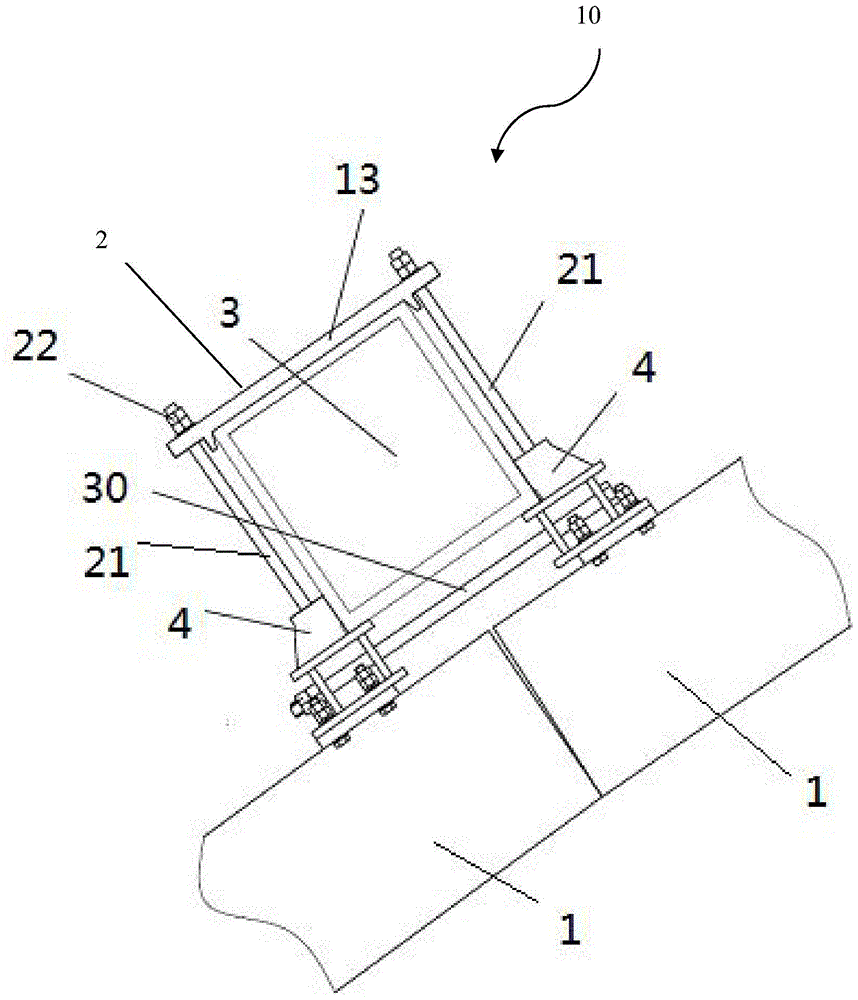

[0020] figure 1 A schematic structural view of an arch bridge inspection vehicle track device 10 (hereinafter referred to as device 10 ) according to the present invention is shown. During actual use, the device 10 is installed under the arches of an arch bridge. An inspection vehicle (not shown) is moved by means of the device 10 to inspect the bridge arch.

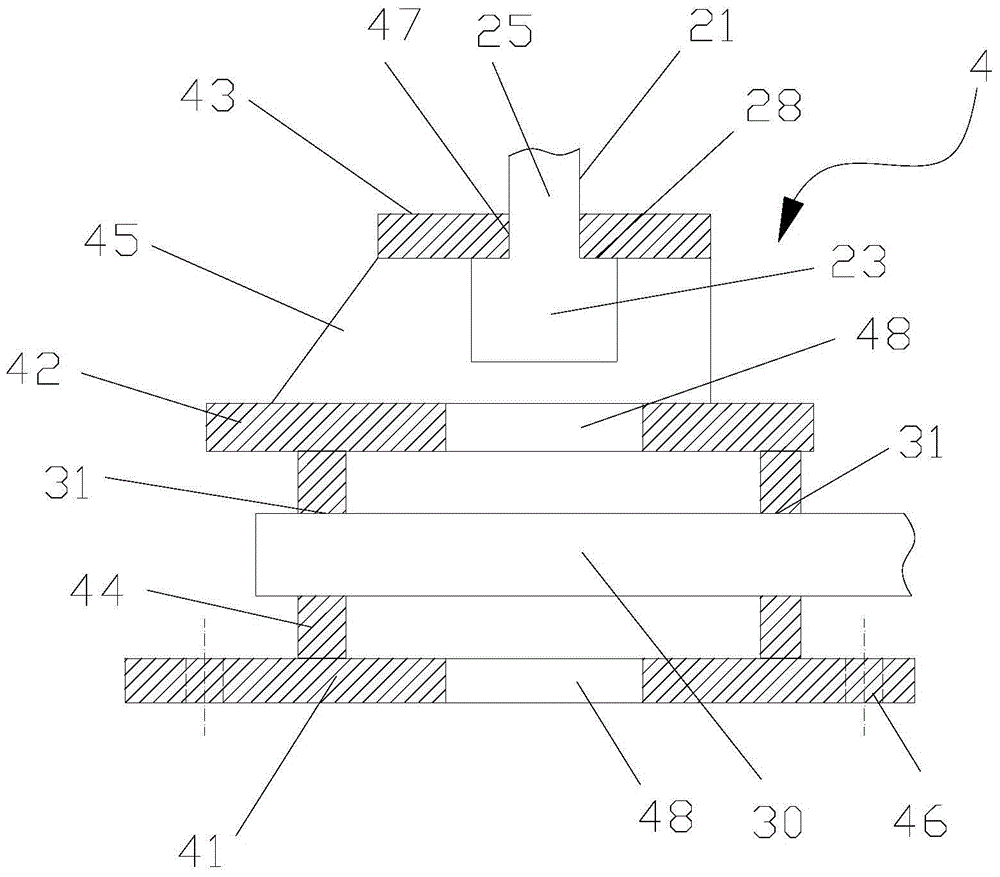

[0021] Such as figure 1 As shown, the device 10 includes a track body 1 and a hoop assembly 2 . The track body 1 is connected with the hoop assembly 2, and the hoop assembly 2 embraces the beam 3 of the arch bridge in a circumferential manner. This achieves the connection of the track body 1 to the arch bridge. This does not need to punch holes on the crossbeam 3 at all, just can connect the track body 1 and the crossbeam 3, the integrity of the arch bridge will not be destroyed, and the safety is just higher. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com