Solid-liquid split charging bottle

A solid-liquid separation and bottling technology, applied in the field of packaging, can solve the problems of inconvenient, separate purchase, and limited shelf life, etc., and achieve the effect of simple structure, easy solid-liquid separation, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

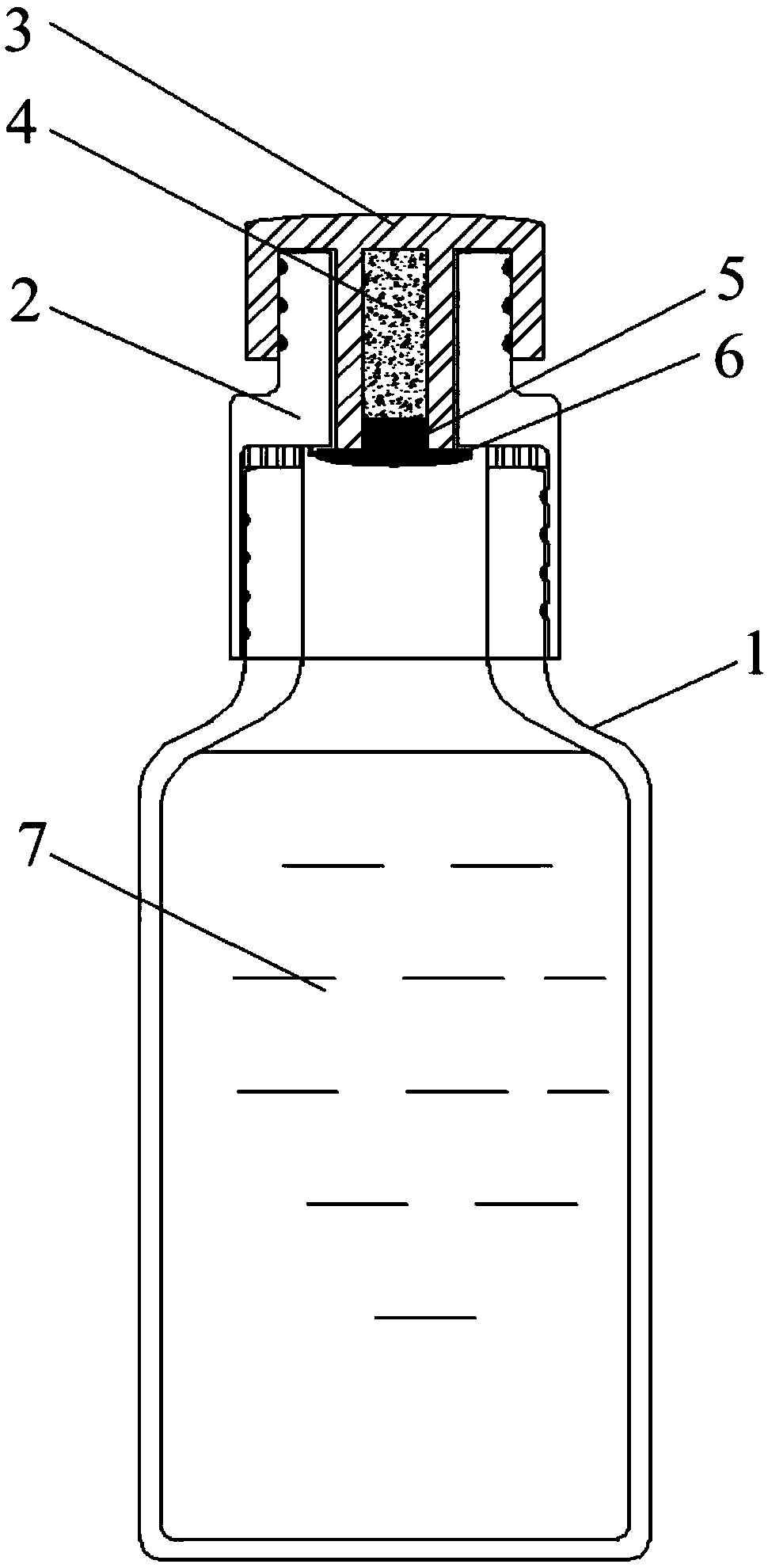

[0025] In order to explain the present invention in more detail and clearly, the embodiment takes the preparation of a cocktail as an example to set forth.

[0026] 1. Pasteurize the bottle body, the first screw cap and the second screw cap.

[0027] 2. Fully mix with 40° white rum and purified water to make 8° colorless concocted wine.

[0028] 3. Screw the first screw cap and the second screw cap together, put the pure blueberry powder into the storage space, and insert the sealing plug into the storage space to isolate the pure blueberry powder from the outside world.

[0029] 4. The colorless prepared wine of 8° is put into the bottle body, the first screw cap is screwed on the bottle, and the openings of the first screw cap and the second screw cap are sealed with heat-shrinkable film, and the packaging is completed.

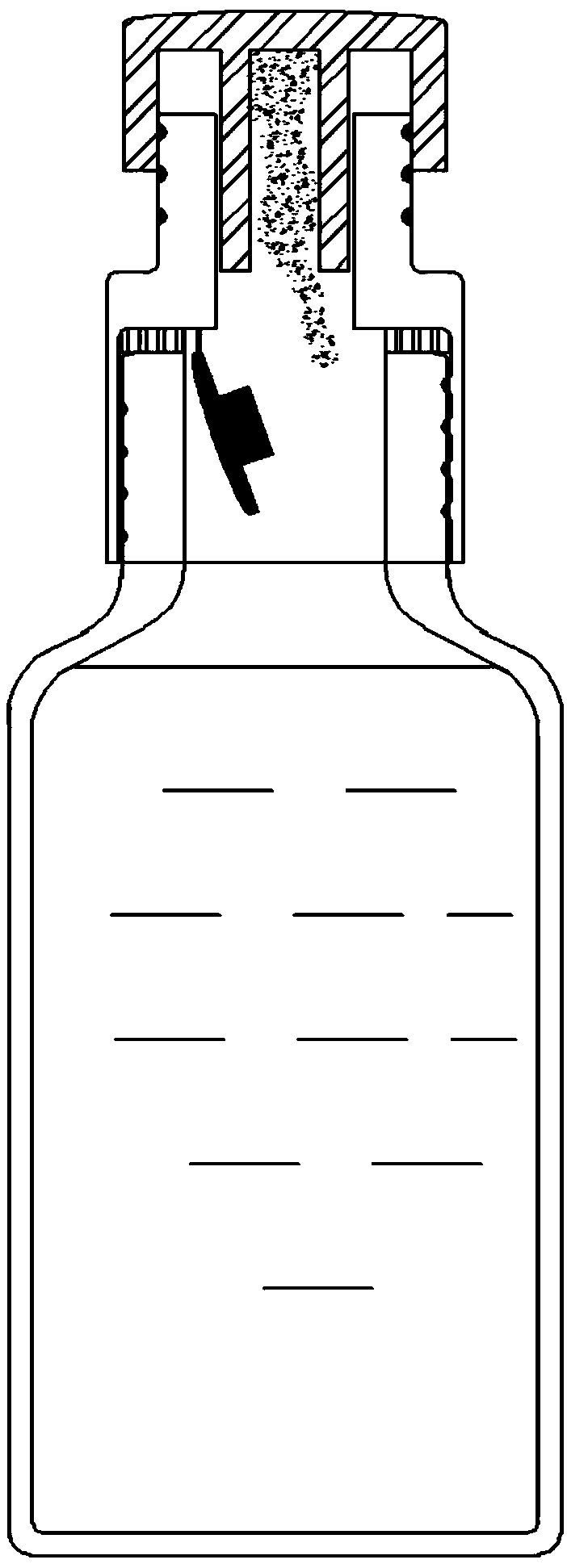

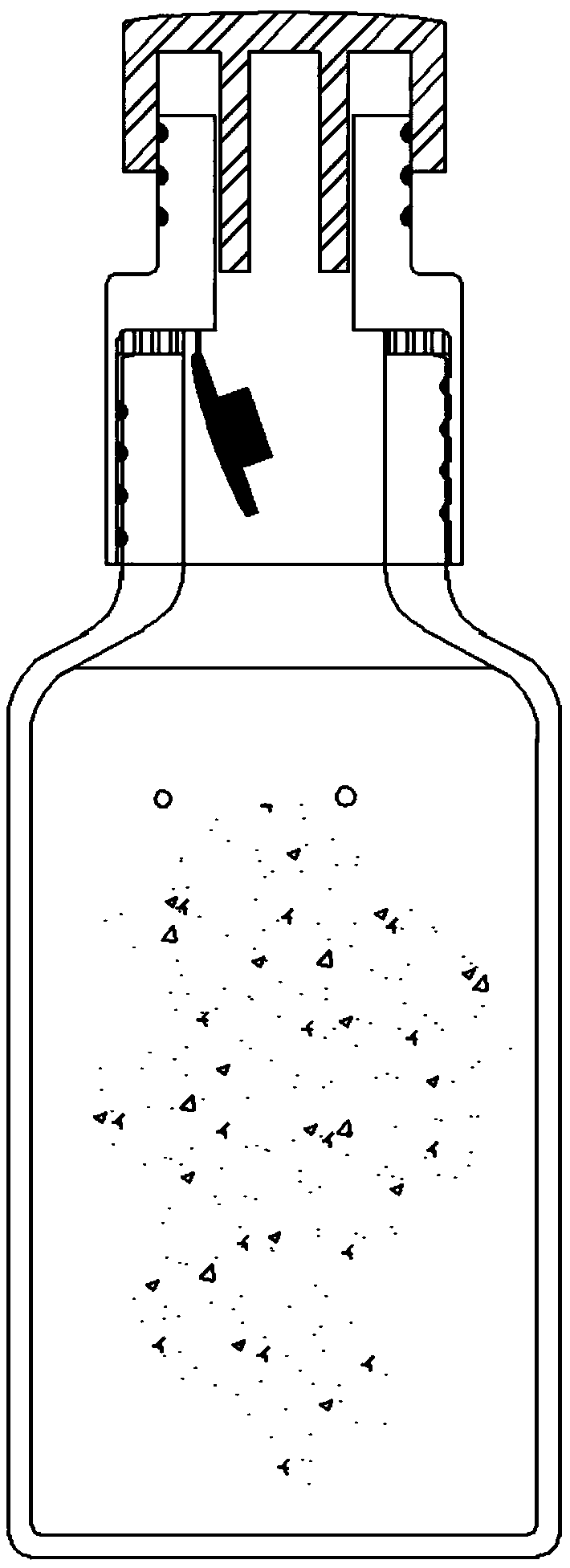

[0030] 5. There is no need to worry about the mixing of solid and liquid during transportation, storage, and sales. When the product reaches the consumer,...

Embodiment 2

[0034] In order to explain the present invention in more detail and clearly, the embodiment takes the preparation of a fruit-flavored carbonated drink as an example to illustrate.

[0035] 1. Pasteurize the bottle body, the first screw cap and the second screw cap.

[0036] 3. Screw the first screw cap and the second screw cap together, put the juice powder into the storage space, and insert the sealing plug into the storage space to isolate the juice powder from the outside world.

[0037] 4. Soda water is put into the bottle body, the first screw cap is screwed onto the bottle, and the openings of the first screw cap and the second screw cap are protected with tear strips, and the packaging is completed.

[0038] 5. There is no need to worry about the mixing of solid and liquid during transportation, storage, and sales. When the product reaches the consumer, first tear off the tear strip of the second screw cap, screw it, and the sealing plug is separated from the storage sp...

Embodiment 3

[0043] The outer diameters of the first screw cap and the second screw cap can be set according to factors such as processing difficulty, customer experience, and aesthetics.

[0044] In the present invention, the cover body of the first screw cap is designed in a "convex" shape, and the second screw cap is nested on the upper part of the first screw cap, that is, the part where the "convex" shape protrudes. The outer diameter of the cap ensures that its outermost wall is flush with the outermost wall of the first screw cap. This design is not only beautiful, but also has a very strong integrity. It is very similar to conventional bottle caps and is easy for consumers to accept.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com