Integrated water purifying and processing equipment

A technology for treatment equipment and water purification, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Insufficient and other problems, to achieve the effect of reducing the cost of water production, saving the cost of energy consumption, and improving the concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

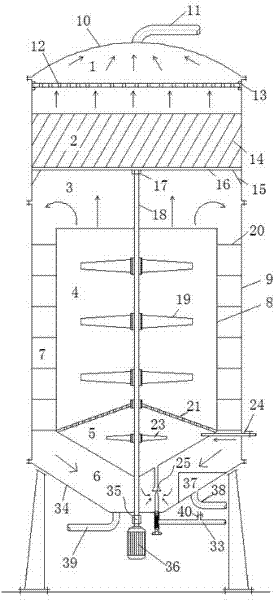

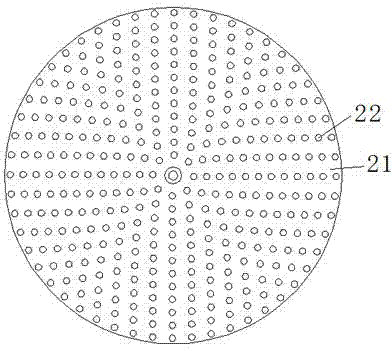

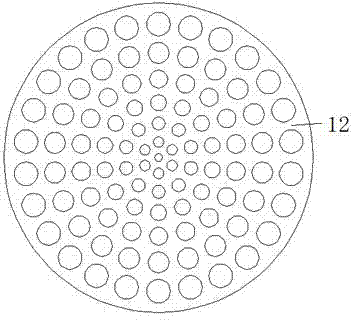

[0029] The design idea of the integrated water purification treatment equipment of the present invention is to organically combine theories and technologies such as mixing, agglomeration and flocculation, shallow sedimentation theory, uniform water distribution theory, and throat backflow principle to integrate coagulation, flocculation, clarification, precipitation, The functions of sludge concentration, automatic sludge return and pressure water outlet are all in one. By adding coagulant for rapid coagulation and sludge hydraulic automatic reflux to absorb and destabilize colloids, the concentration of sludge in the primary flocculation reaction zone is kept stable, and in the agglomeration flocculation zone, the high-concentration suspension layer is used to re-adsorb and mechanically stir and shear to form dense and Flocs with good settling performance, based on the shallow sedimentation theory, the mud-water separation and sludge concentration are respectively set, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com