Shunt valve with water release function and closestool cover plate provided with shunt valve

A technology of water diversion valve and function, applied in the field of sanitary ware, can solve the problems of not having the ability to drain the residual water of the water diversion valve, complex flushing control procedures, and unfavorable human health, so as to avoid the breeding of bacteria, simple and feasible structure, and ingenious design concept Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

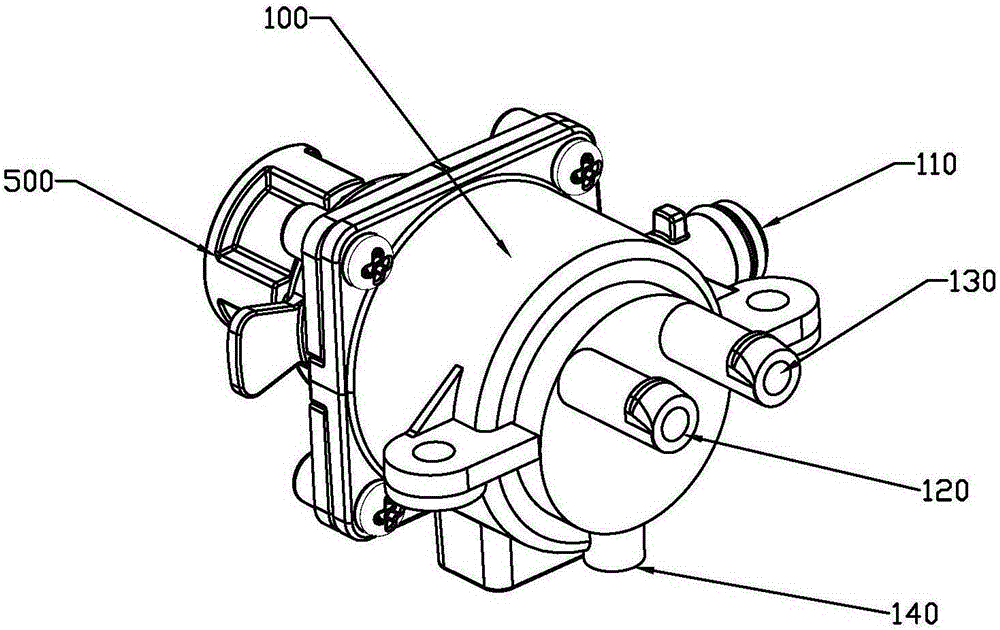

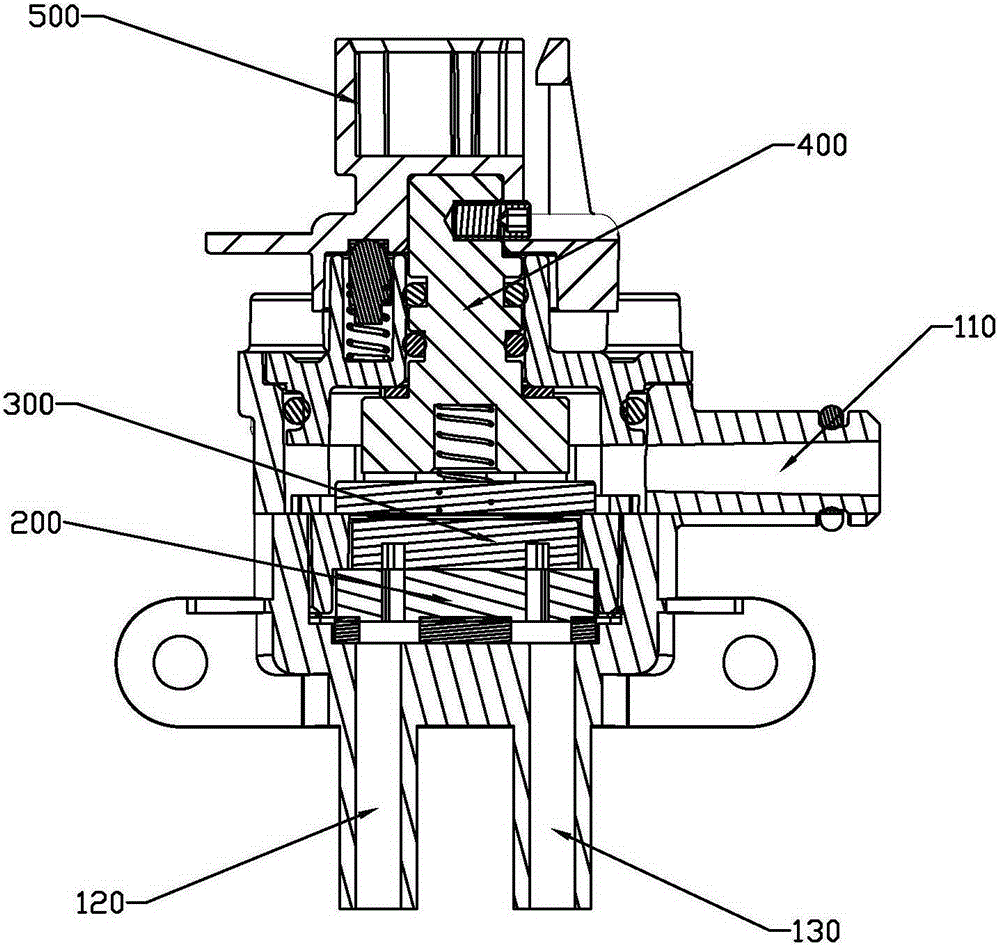

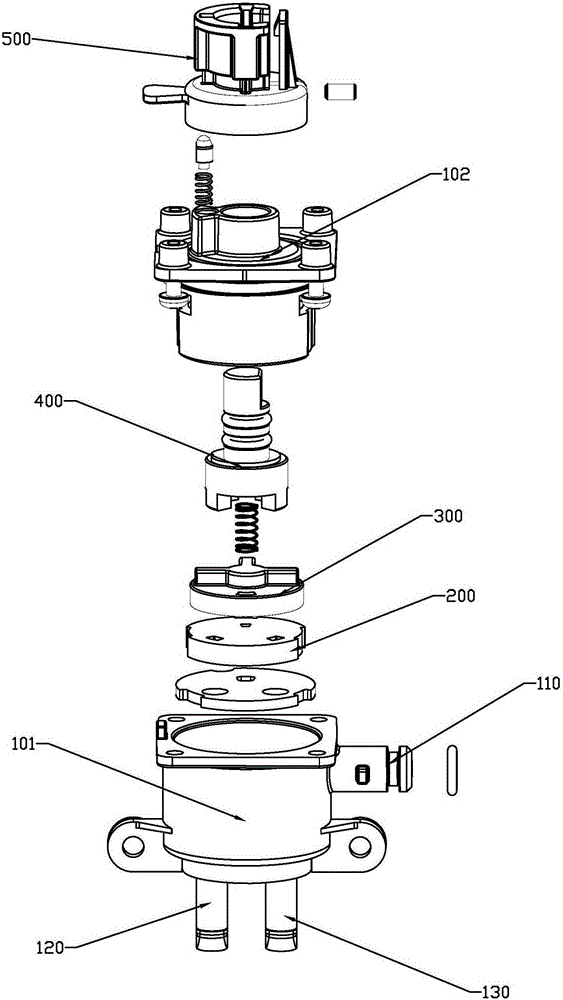

[0062] The first embodiment (the water diversion valve includes a water passage and a water discharge passage)

[0063] Such as Figure 1 to Figure 12 As shown, a water diversion valve with a water discharge function in this embodiment includes a water passage and a water discharge channel. When the water diversion valve is opened, the water passage is opened and the water discharge channel is closed, and the water flows through The water passage of the water diversion valve flows into the outlet pipe connected to the rear end of the water diversion valve; The residual water in the pipeline is discharged through the drain channel.

[0064] In this embodiment, the water diversion valve includes a valve body 100 and a valve core. The valve body 100 is provided with a water inlet 110, a water outlet, and a water discharge port 140. The first valve plate 200 and the second valve plate 300 arranged in the inner cavity of the valve body 100, wherein the first valve plate 200 is pr...

no. 2 example

[0069] The second embodiment (the water diversion valve includes a water passage, a backflow passage, and a water discharge passage)

[0070] Such as Figure 13 to Figure 24 As shown, in this embodiment, the main difference from the water diversion valve of the above-mentioned first embodiment is that: it also includes a backflow channel, which includes a backflow water outlet 150, a backflow water inlet 160, The return pipe 700 is externally connected to the valve body 100 and communicated with the return outlet 150 and the return inlet 160 , and a return outlet hole in communication with the return outlet 150 is provided on the first valve plate 200 240, the backflow water inlet 250 communicated with the backflow water inlet 160, and the second valve plate 300 is provided with a backflow groove 350 communicated with the backflow water inlet 250, and the backflow groove 350 is connected with The drainage groove 322 and the outlet groove are connected to each other.

[0071]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com