Electric valve

An electric valve and valve seat technology, which is applied to valve devices, valve details, engine components, etc., can solve the problems of high production cost, high product cost, complicated manufacturing process, etc., and achieve production cost and product cost restraint and discharge restraint. phenomenon, the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will be described below with reference to the accompanying drawings.

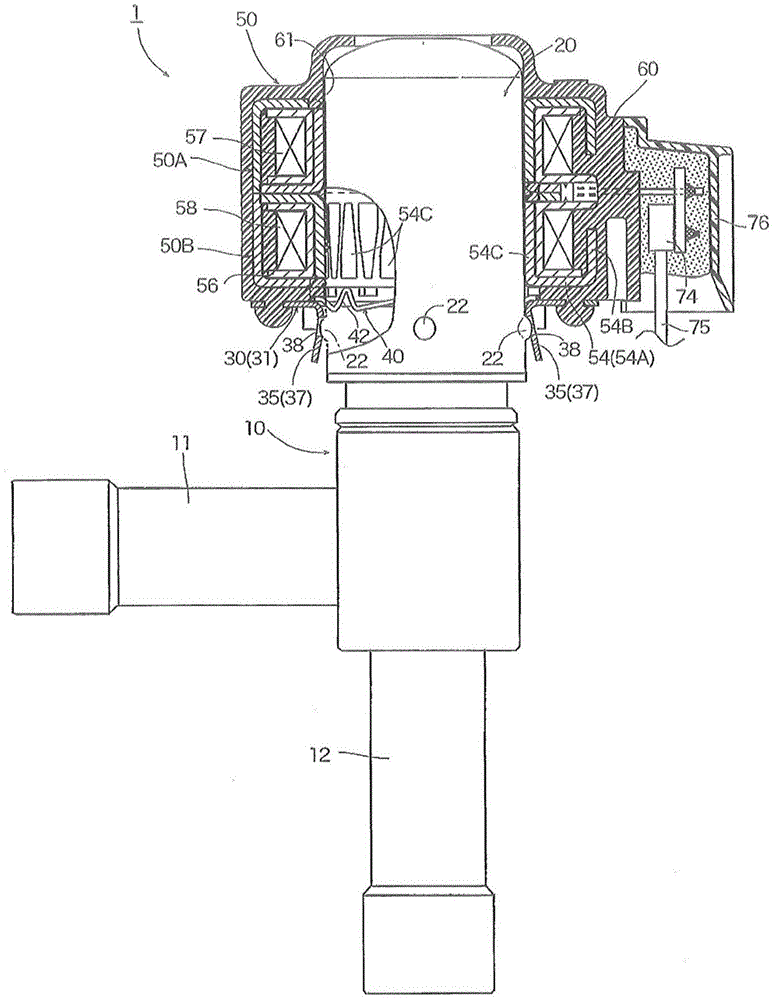

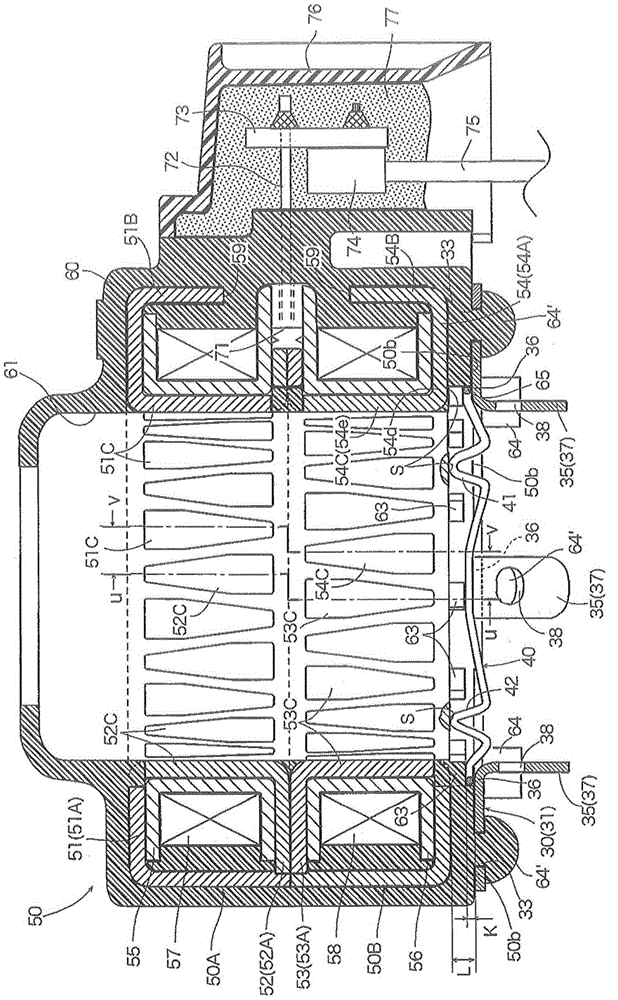

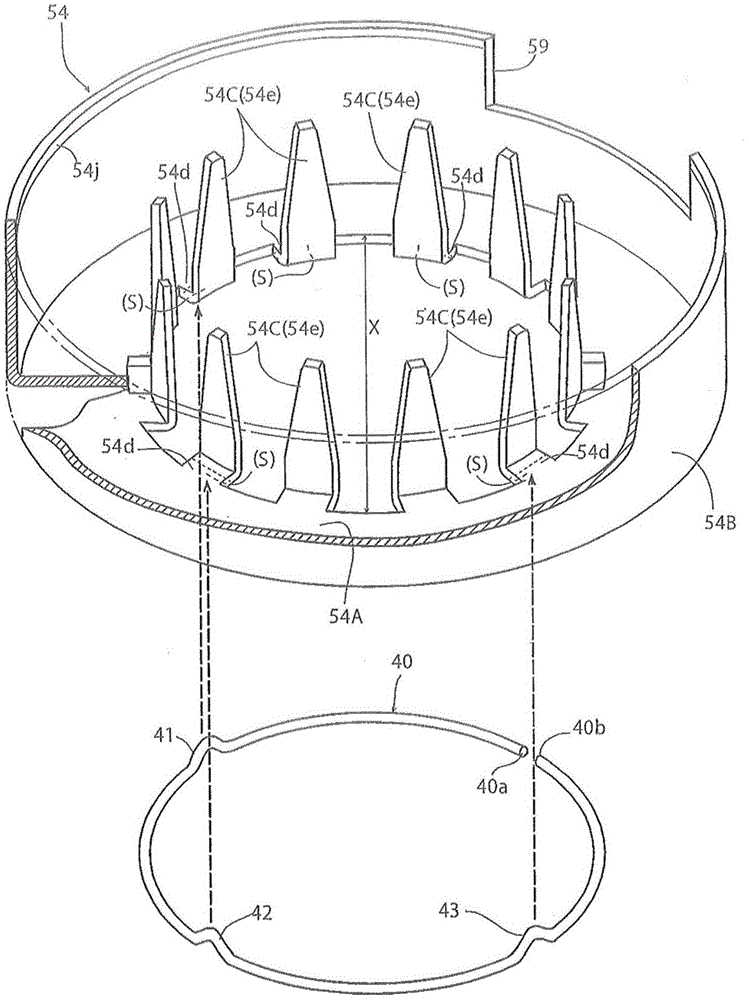

[0059] figure 1 It is a partial cutaway front view showing an embodiment of the electric valve of the present invention, figure 2 is externally embedded in figure 1 A schematic cross-sectional view of the stator part before the housing is shown, image 3 is indicated together with the conduction spring as figure 2 A partial cutaway perspective view of the yoke, one of the structural elements of the stator shown, Figure 4 yes figure 2 Bottom view of the stator (single piece) shown, Figure 5 yes figure 2 Bottom view of the stator in the state shown (state with the anti-rotation member and conduction spring installed).

[0060] The electric valve 1 shown in the figure has the same structure as that described in Patent Document 1, etc., and the lower end portion of a cylindrical housing 20 with a top is hermetically bonded to the valve body 10 by means of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com