Disc-shaped disc hub core thickness detection method

A technology of thickness detection and disc hub, which is applied in the field of automobile manufacturing, can solve the problems of troublesome detection, heavy detection workload, and low detection efficiency, and achieve the effects of small detection workload, fast operation, and improved detection speed and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

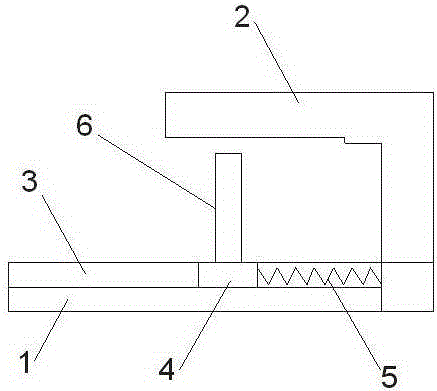

[0017] Example: see figure 1 , a method for detecting the thickness of a disc-shaped hub core, using a semi-automatic detection tool, the semi-automatic detection tool includes a rectangular detection bottom plate 1 and a detection top plate 2, the length of the detection top plate 2 is less than the length of the detection bottom plate 1. One end of the detection top plate 2 is bent downward and fixedly connected to the detection bottom plate 1, wherein the upper side of the detection bottom plate 1 is a plane, and the lower side of the detection top plate 2 is a stepped surface. The distance between the section of the stepped surface close to the bending section and the detection base plate 1 is smaller than the distance between the section away from the bending section and the detection base plate 1, so that the section between the detection top plate 2 and the detection base plate 1 away from the bending section A detection pass gauge is formed, and a section close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com