Automatic material issuing method and system

An automatic and material-feeding technology, applied in the field of transportation, can solve problems such as low efficiency and queue-cutting transportation efficiency, and achieve the effect of solving contradictions, improving efficiency, and eliminating human causes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

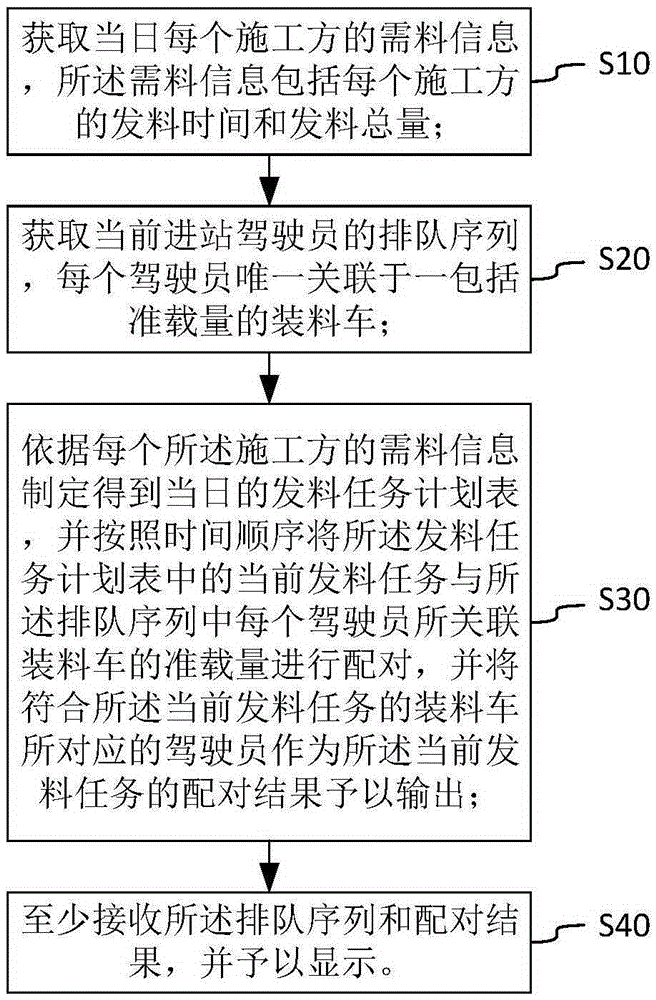

[0032] In order to ensure that the drivers queuing up at the mixing plant can carry out the transportation work fairly without affecting the material delivery requirements of the construction site, please refer to figure 1 , figure 1 A flow chart of the realization of an automatic material delivery method provided by the present invention is given, and the detailed realization steps of the method will be described below.

[0033] Step S10, obtaining the material demand information of each construction party on the day, and the material demand information includes the delivery time and the total amount of material delivery of each construction party.

[0034] In practice, the daily concrete demand of each construction site is different. Therefore, the construction party will generally send the concrete demand information to the mixing station one day in advance. Among them, the material demand information of each construction party includes the delivery time and the total amo...

Embodiment 2

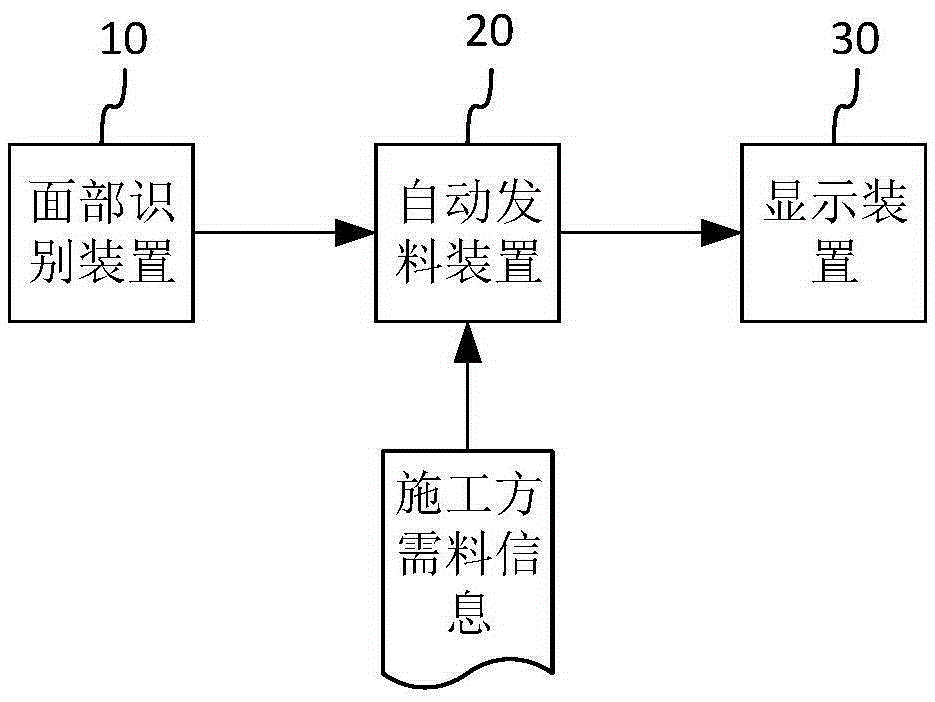

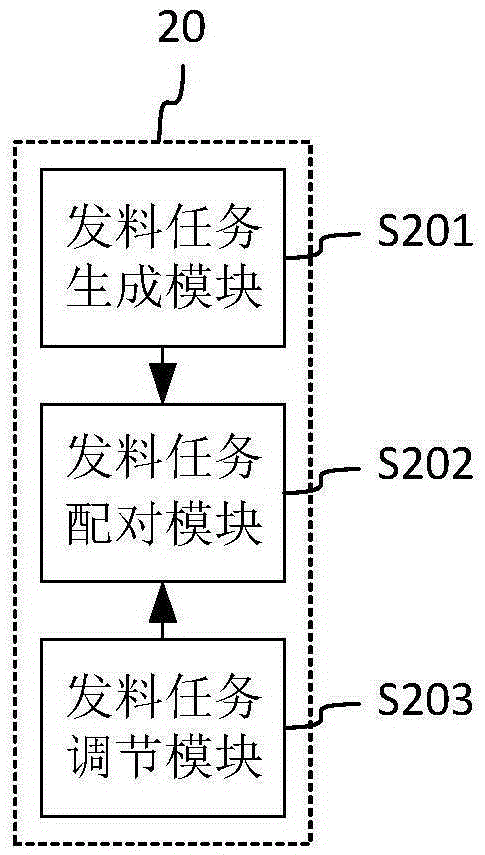

[0063] See figure 2 , the present invention also provides an automatic material delivery system, including: a facial recognition device 10, used to obtain the material demand information of each construction party on the day, and the material demand information includes the material delivery time and material delivery time of each construction party. Total amount; automatic material sending device 20, used to obtain the queuing sequence of the current driver entering the station, each driver is uniquely associated with a charging car that includes the quasi-loading capacity; and according to the required material information of each described construction party Formulate the material issue task schedule, pair the current material issue task in the material issue task schedule with the quasi-loading capacity of the loading vehicle associated with each driver in the queue sequence in chronological order, and match the The driver corresponding to the loading vehicle of the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com