Wafer scheduling method and system

A dispatching method and dispatching system technology, applied in electrical components, conveyor objects, transportation and packaging, etc., can solve problems such as ineffective utilization, low transmission efficiency, and reduced transmission efficiency, so as to reduce waiting time and improve dispatching. Efficiency, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

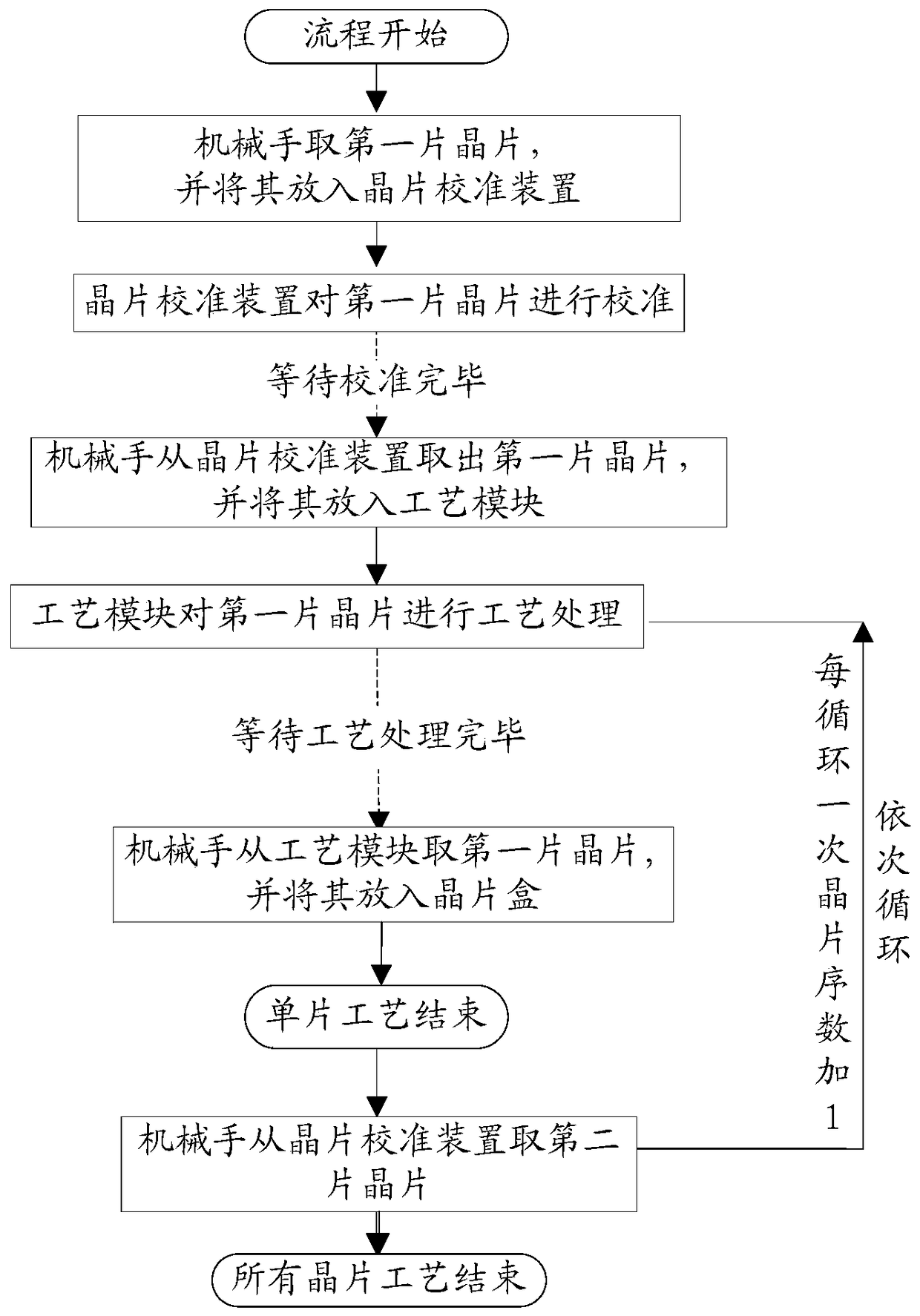

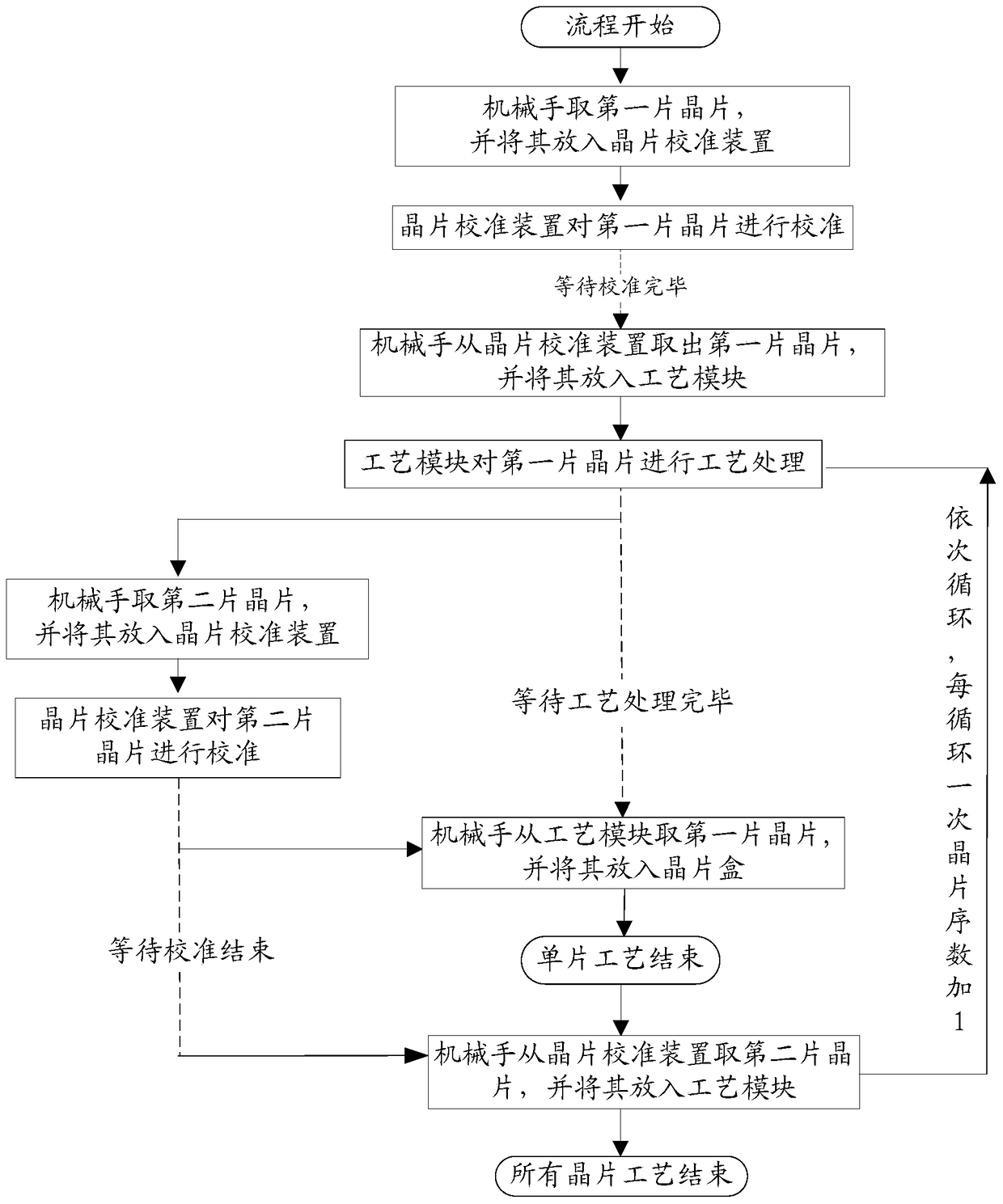

[0037] The specific implementation manners of the wafer scheduling method and system in the embodiments of the present invention will be described below with reference to the accompanying drawings.

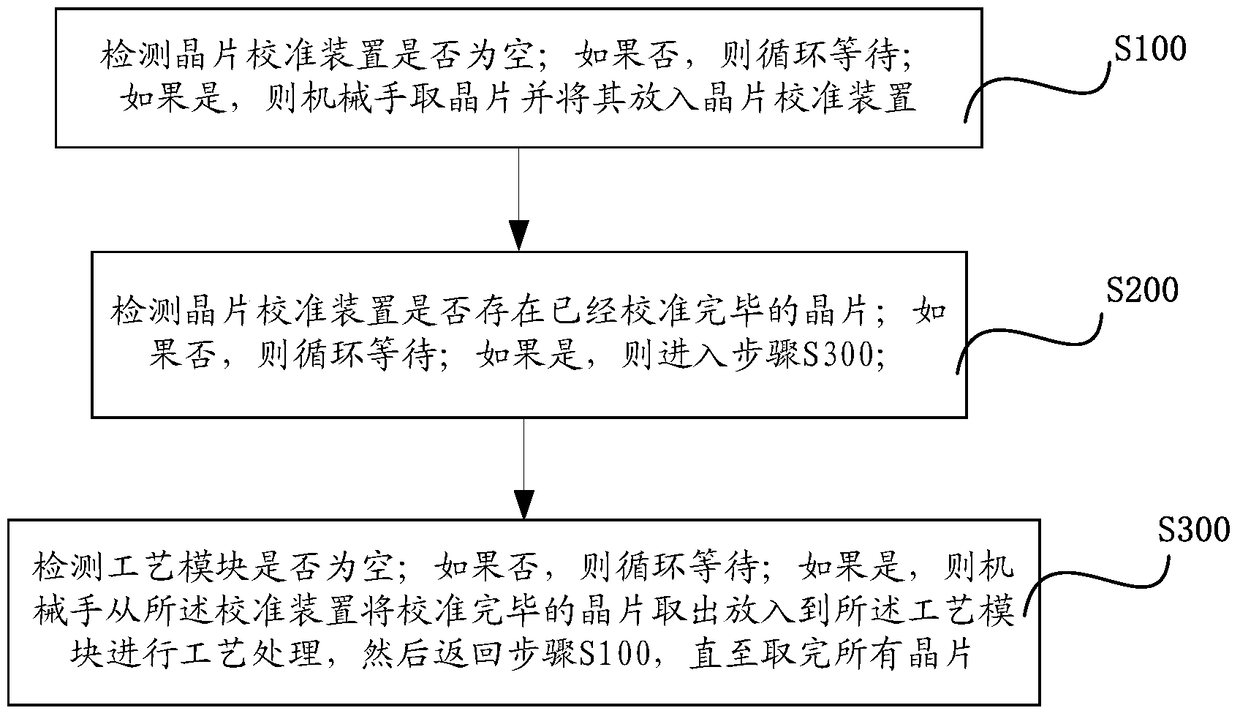

[0038] refer to figure 2 , the invention provides a method for scheduling wafers, comprising the following steps:

[0039] S100: Detect whether the wafer alignment device is empty; if not, enter step S200; if yes, the manipulator obtains the wafer and puts it into the wafer alignment device for calibration;

[0040] When the wafer calibration device is not empty, it means that there is a wafer in the wafer calibration device. At this time, enter step S200 to detect whether the calibration of the wafer in the calibration device is completed; when it is empty in the wafer calibration device, it means that there is no wafer in the wafer calibration device. , at this time, the manipulator is required to obtain the wafer and put it into the calibration device for calibration.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com