Battery grouping method and battery grouping system

A battery and matching technology, used in secondary batteries, secondary battery testing, secondary battery manufacturing, etc., can solve the problems of large errors, low efficiency, poor balance, etc., to prevent misjudgment, reduce misjudgment rate, Reduce the effect of inaccurate capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

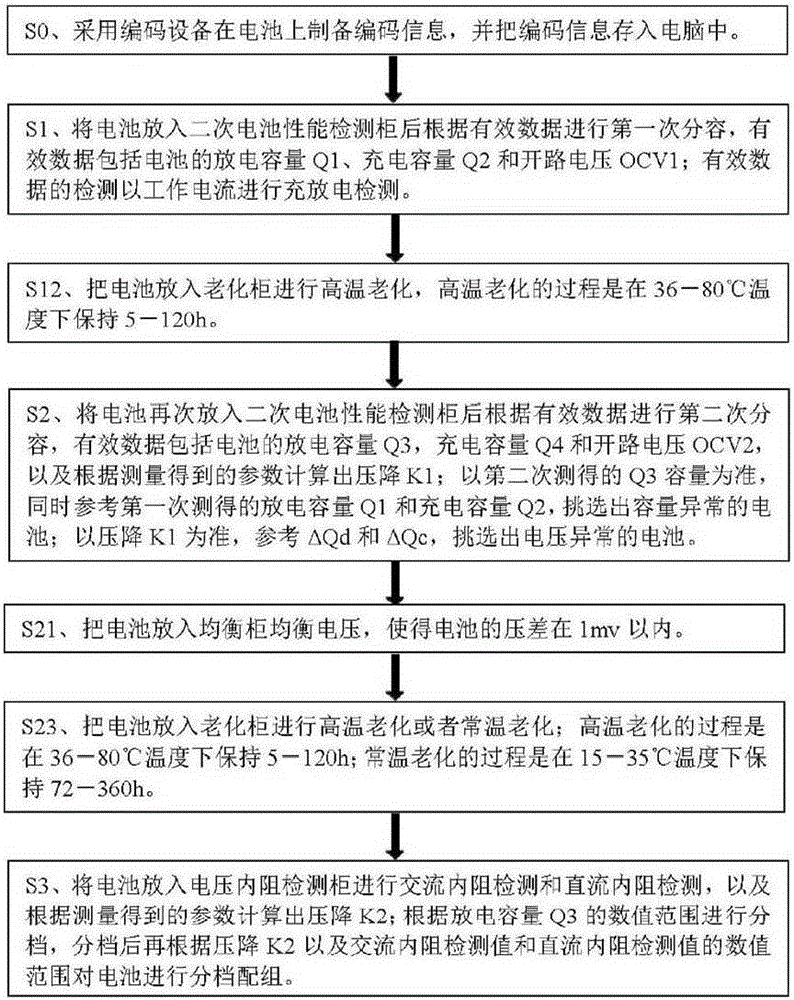

[0040] see figure 1 As shown, a battery matching method of the present invention includes the following steps:

[0041] S0. Use coding equipment to prepare coding information on the battery, and store the coding information in the computer; the coding equipment can be a scanning gun and a printer, and the battery identification information is printed on the surface of the battery through the printer, and then use the scanning gun Scan the battery to obtain coded information; before performing steps S1, S2 and S3, use a scanning device to scan and record the coded information on the battery, store the detection data and coded information of the battery in a database, and the computer include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com