A miniature vertical lathe

A vertical lathe and micro technology, applied in the field of lathes, can solve the problems of slow tool changing speed, high precision of manipulators, and long production time of lathes, and achieve the effects of shortening downtime, reducing volume, and avoiding parking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

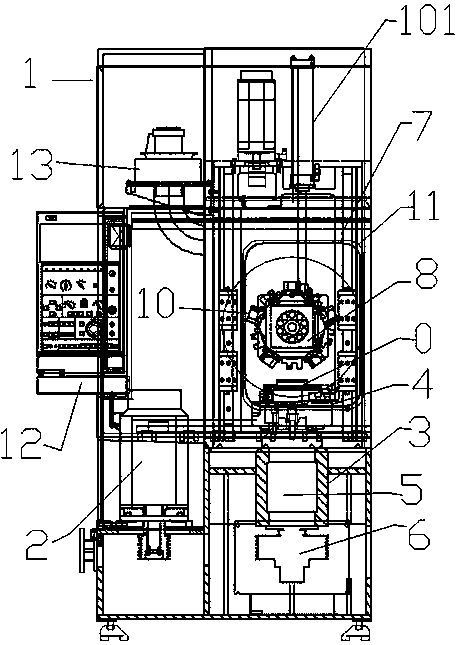

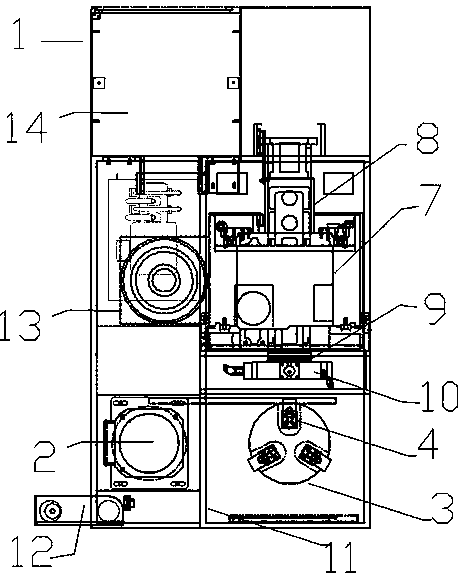

[0017] Such as figure 1 and figure 2 Shown, the present invention provides miniature vertical lathe:

[0018] Including chassis 1, servo motor 2, spindle 3, three-jaw chuck 4, oil tank 5, rotary cylinder 6, column 7, slide table 8, configuration seat 9, turret 10, protective device 11, limit switch 101, control panel 12. Dust collector 13, characterized in that:

[0019] A servo motor 2 is installed at the inner bottom of the chassis 1, the servo motor 2 is connected to the main shaft 3 through a transmission device, the servo motor 2 drives the main shaft 3, and a hydraulic three-jaw chuck 4 is installed on the working surface of the main shaft 3, The hydraulic three-jaw chuck 4 is connected to the fuel tank 5 and the rotary cylinder 6, and the fuel tank 5 and the rotary cylinder 6 are installed inside the main shaft 3 to save space. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com