Drag plate of knife grinder

A knife grinder and carriage technology, which is applied in the direction of grinding frame, grinding slide, grinding bed, etc., can solve the problems of poor lubrication effect, low feeding efficiency, complex structure, etc., and achieve high feeding efficiency , good lubricating performance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

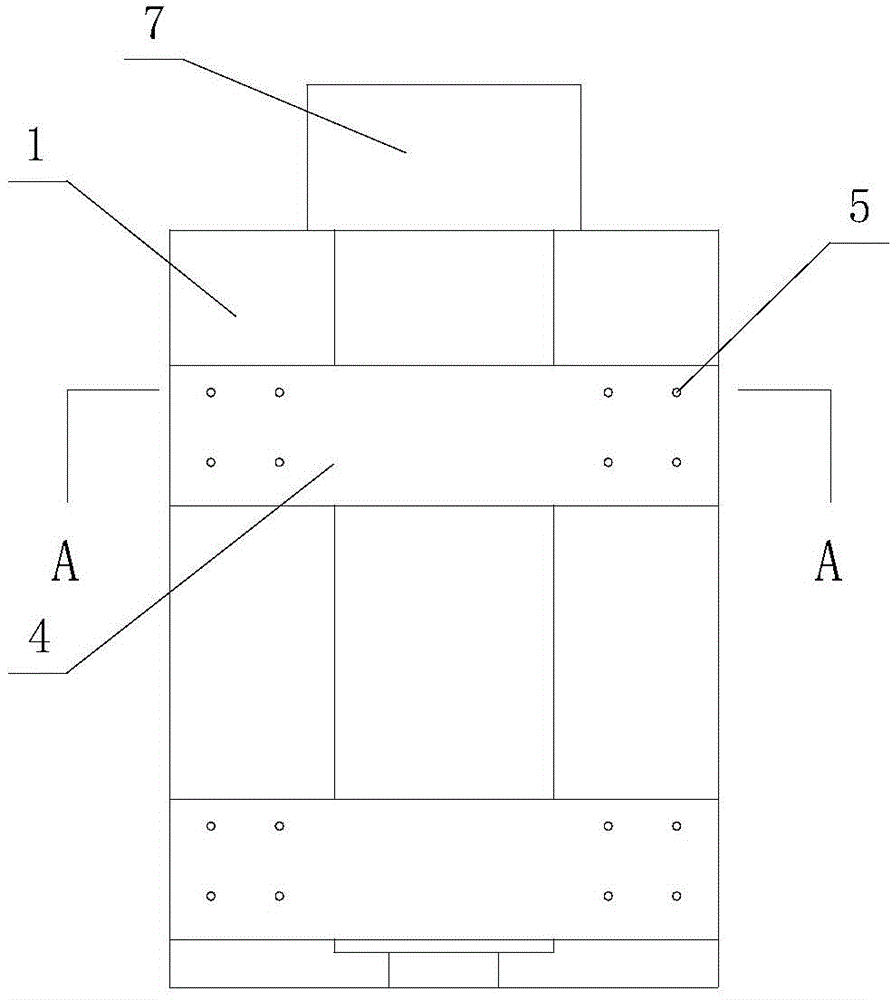

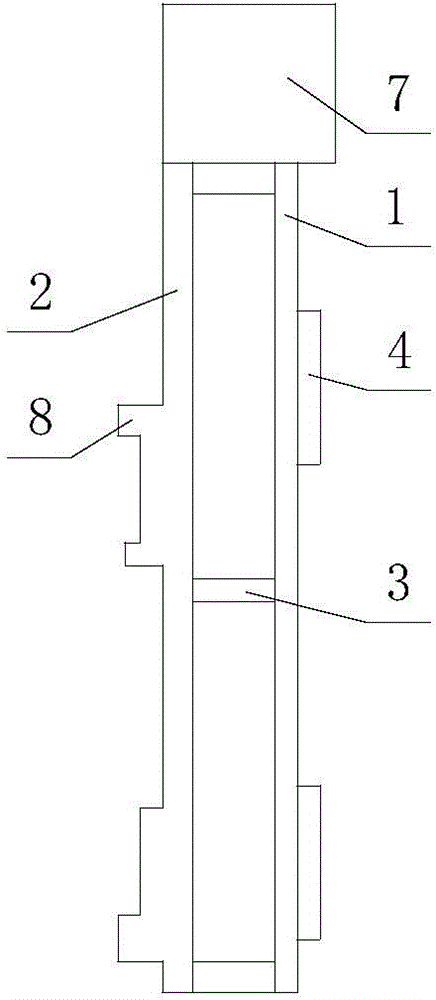

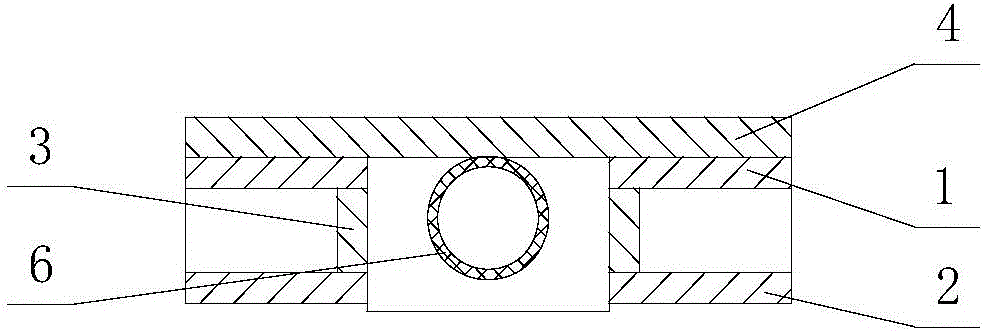

[0016] Such as figure 1 , figure 2 with image 3 A knife grinder carriage shown includes an upper plate 1 and a lower plate 2, a vertical plate 3 is connected between the upper plate 1 and the lower plate 2, and the upper plate 1 and the lower plate 2 are respectively arranged in parallel by two plates, In the cavity formed between the upper plate 1 and the vertical plate 3, there is a screw casing 6 which is sleeved on the screw and is slidably connected with the screw; The connected mounting plate 4 is provided with a motor box 7 at one end of the upper plate 1; the lower plate 2 is provided with a foot 8 connected with the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com