TPV (Thermoplastic Vulcanizate) used in automobile antenna material and preparation method of TPV

A technology for automotive antennas and compounds, applied in the field of TPV for automotive antenna materials and its preparation, can solve the problems of poor UV absorber effect and unstable system

Inactive Publication Date: 2016-02-10

ANHUI XIONGYA PLASTIC TECH

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the effect of the UV absorber added in this simple blending method is not good. Due to the existence of phase separation, there is a big problem in compatibility, and the UV absorber will slowly polymerize after a long time precipitated in the substance, causing the instability of the system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0156]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

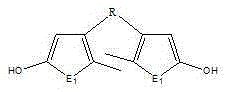

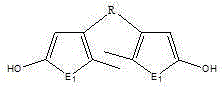

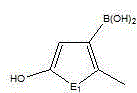

TPV (Thermoplastic Vulcanizate) used in an automobile antenna material is prepared by conducting dynamic vulcanization on a vulcanization mixture. The vulcanization mixture at least comprises the following raw materials in parts by weight: 0.1 to 3 parts of grafted thermoplastic polymer, 100 parts of vulcanizable elastomer, 50 to 200 parts of thermoplastic polyolefin, 0.01 to 10 parts of a cross-linking agent, and 10 to 100 parts of filling oil, wherein the grafted thermoplastic polymer is obtained by modifying a diarylethene compound. The invention relates to the field of TPV, in particular to the TPV used in the automobile antenna material and a preparation method of the TPV.

Description

technical field [0001] The invention relates to the field of thermoplastic vulcanizate (TPV), in particular to TPV for automotive antenna materials and a preparation method thereof. Background technique [0002] TPV (thermoplastic vulcanizate) is a new green chemical material, which has the elasticity of rubber and the strength of engineering plastics. Compared with rubber, it has better processing performance and longer service life; compared with engineering plastics, it also has High strength, better flexibility and dynamic mechanical properties. The processing of traditional rubber materials consumes a lot of energy and cannot be recycled. TPV materials do not require two energy-intensive processes of mixing and vulcanization, and can be directly heated and formed to manufacture rubber products. TPV material has high plasticity and elasticity, and can be processed, used and recycled repeatedly. [0003] The automobile industry and machinery industry are the pillar ind...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/16C08L91/00C08L35/00C08L33/02

CPCC08L23/12C08L23/16C08L91/00C08L2205/03C08L2205/035C08L2312/00C08L35/00C08L33/02

Inventor 葛军

Owner ANHUI XIONGYA PLASTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com