Toilet with functions of pressure conduction and force-combined replacement

A technology of toilets and water guiding rings, applied in water supply devices, flushing toilets, buildings, etc., can solve problems such as troublesome operation, and achieve the effect of enhanced washing function, enhanced washing function, and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

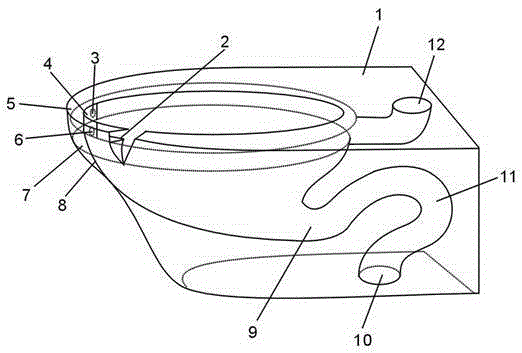

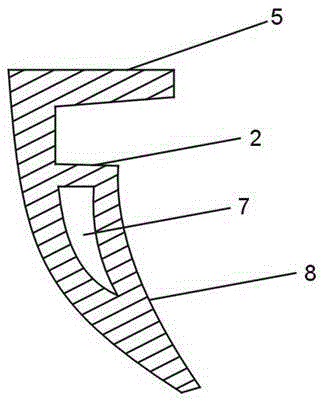

[0016] figure 1 and figure 2 The schematic diagram of the overall structure and the schematic diagram of the cross-sectional structure of the pressure-guiding combined force displacement toilet of the present invention are respectively shown.

[0017] figure 1 Middle: panel 1 and seat ring 5 are on the same plane. The rear portion of the panel 1 is provided with a water outlet 12 , and a left water outlet 6 and a right water outlet 3 are provided under the seat ring 5 at the front of the panel 1 . The connecting plate between the left water outlet hole 6 and the right water outlet hole 3 is a water retaining plate 4, and a water dividing platform 2 is arranged below it. A water guide ring 7 is provided under the water platform 2 . The bedpan 8 smoothly connects the water guiding ring 7 and the sewage pipe inlet 9 . The end of the sewage pipe 10 is the sewage pipe outlet 11 .

[0018] figure 1 Middle: the bedpan 8 is structured together with the water guiding ring 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com