Moving safety stop door

A door-blocking and safety technology, which is applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of safety impact on scaffolding personnel, low safety factor of scaffolding, and loss of construction units, etc., so as to save physical exertion, Reduce security, use solid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

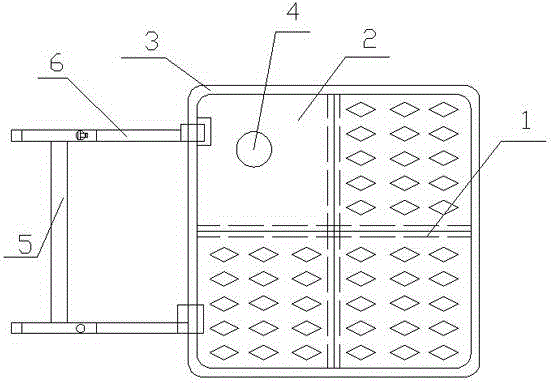

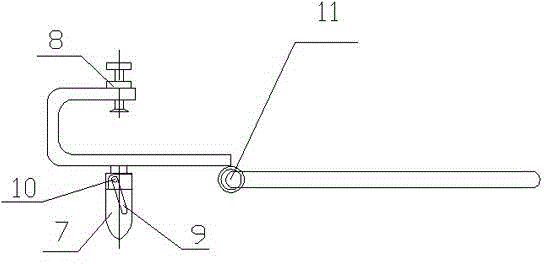

[0012] A movable safety door, including a skeleton 1 and a baffle 2, the skeleton 1 adopts a cross-shaped skeleton, the skeleton 1 is welded by vertical and horizontal square hollow tubes, the skeleton 1 is surrounded by a fixed bracket 3, and the fixed bracket 3 surrounds the cross skeleton , the fixed bracket 3 is spliced by circular hollow tubes, the fixed bracket 3 fixes the cross frame by welding, and the baffle plate 2 is laid on the cross frame, the baffle plate 2 is spliced by four steel plates, the steel plate has three hollow steel plates and a It is composed of hollowed out steel plates, the non-hollowed out steel plate is a rhombic pattern steel plate, the hollowed out steel plate is made of mesh, the non-hollowed out steel plate is provided with mounting holes 4, and the fixing bracket 3 is provided with a supporting device, which is composed of a balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com