Liquid fuel cooking range

A technology of liquid fuel and stove, applied in the field of stove, to achieve the effects of precise control, simple structure and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

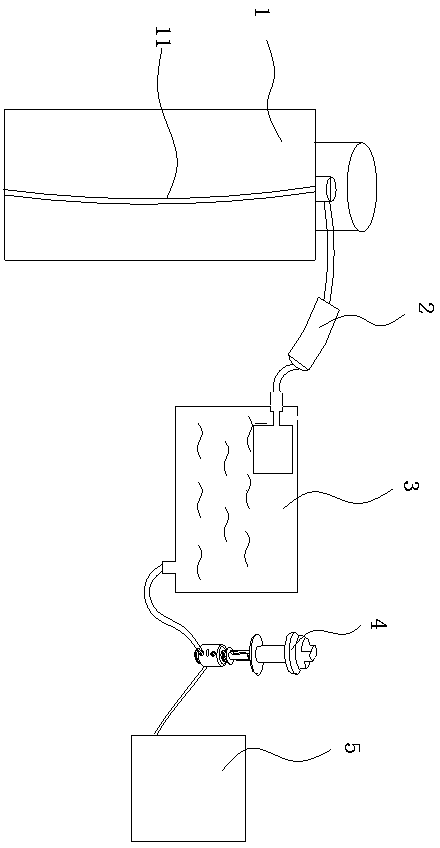

[0038] refer to figure 1 , the liquid fuel stove of the present invention includes a steel cylinder 1 , a filter 2 , a voltage regulator 3 , a switch 4 and a burner 5 . Wherein the valve of steel cylinder 1 is connected with a liquid pipe 11, and the end of liquid pipe 11 goes straight to the bottom of steel cylinder 1, and 1~2 atmospheric pressure is filled in steel cylinder 1, to ensure that the atmospheric pressure can continuously press liquid into liquid pipe 11. The valve thread port of the cylinder 1 is connected with the inlet of the filter 2, and the liquid flowing out from the liquid pipe 11 flows into the filter 2. The outlet of the filter 2 is connected with the inlet of the voltage stabilizer 3 , the outlet of the voltage stabilizer 3 is connected with the switch 4 , and the switch 4 is connected with the burner 5 to control the combustion of fuel in the burner 5 .

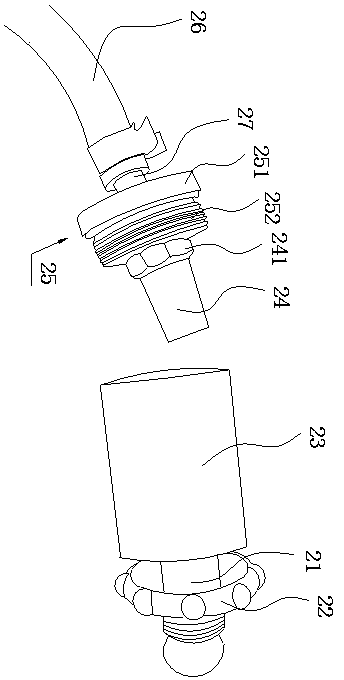

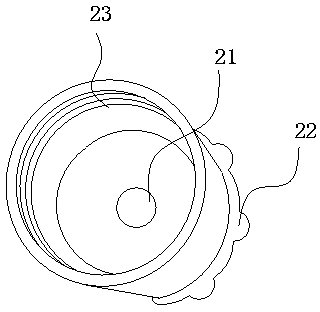

[0039] refer to figure 2, The filter 2 includes an outlet pipe 21, a valve 22, a filter outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com