Sealing tester of motor

A technology of sealing test and sealing test seat, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of motor parts such as corrosion, loss of efficacy, and high cost, and achieve production The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

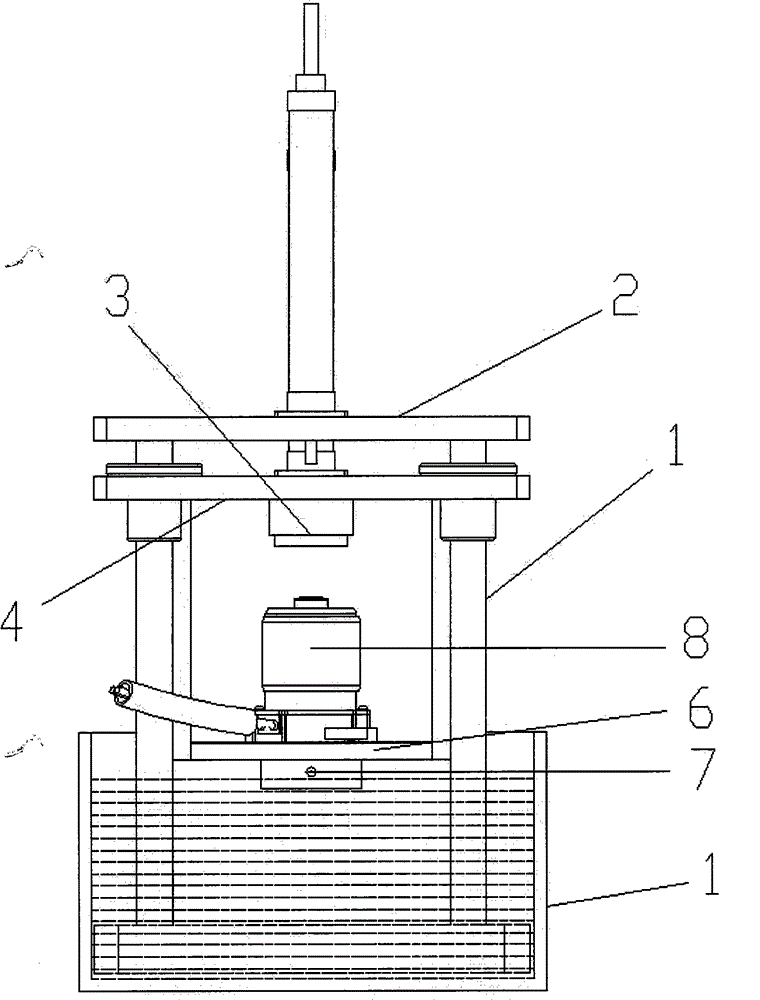

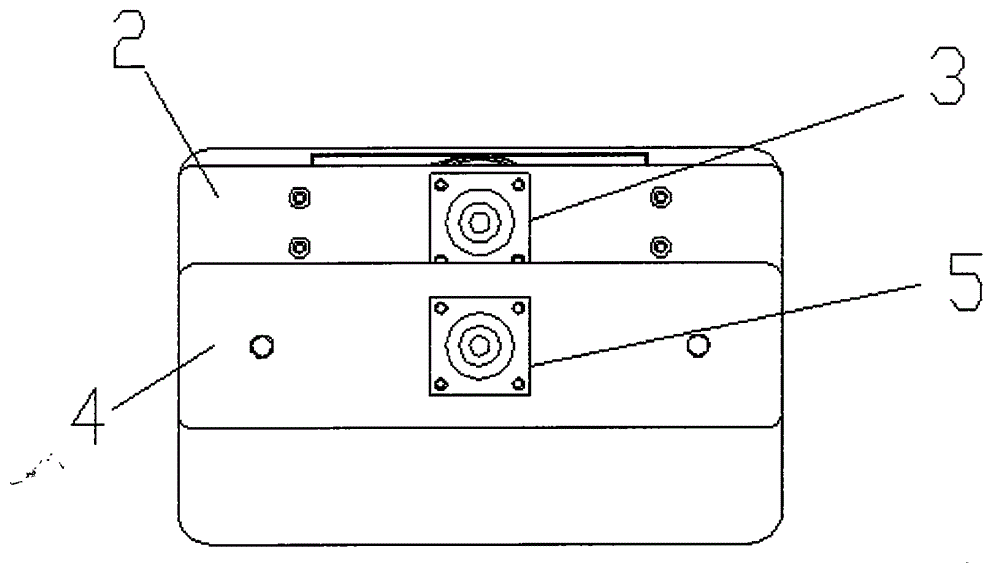

[0010] Such as figure 1 , figure 2 A motor sealing test machine shown includes a water tank 1 filled with water, two vertically parallel first hydraulic presses 2 and second hydraulic presses 4 are fixedly arranged in the water tank 1, and the end of the piston rod of the first hydraulic press 2 is provided with a press Tighten the motor pressure head 3, a sealing test seat 6 is arranged directly under the compression motor pressure head 3, and an air inlet 7 is arranged on the sealing test seat 6, and a vent pipe is connected on the air inlet 7, and the test motor 8 is fixed on the air inlet 7. On the sealing test seat 6, the compression motor pressure head 3 presses the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com