Color grade determination method for defect in roller through airborne flaw detector

A flaw detector and technology for rolls, which are applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems affecting the efficiency of roll defect detection and the inability to make intuitive and correct determinations of defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for determining the color progression of roll defects by the airborne flaw detector of the present invention comprises the following steps:

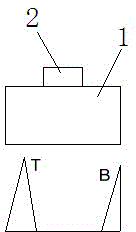

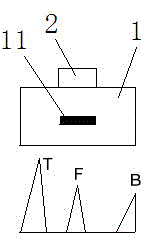

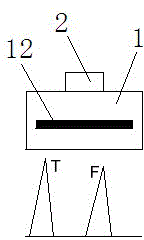

[0031] Step 1. Use A-type pulse reflection ultrasonic flaw detector to detect flaws in the working layer and bonding layer of the roll. It is set that there must be no defects greater than Ф2 equivalent in the roll. The sensitivity of the flaw detector is set to adjust the primary wave height to 60% of the full screen. Then increase 6dB as the benchmark sensitivity;

[0032] Step 2. The flaw detector uses four sets of dual-crystal straight probes, and the height of the ultrasonic wave amplitude is used as the evaluation index value. The measured value is the echo value received by the conventional probe, and the displayed value is expressed after conversion;

[0033] Step 3. Set the measured value and displayed value to satisfy the following formula,

[0034] y=1.8x+0.1

[0035] In the formula, y is the displayed valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com