Micro resistor measurement gripper of damage detection of metal materials and usage method thereof

A technology for measuring fixtures and metal materials, used in measuring devices, measuring device casings, measuring resistance/reactance/impedance, etc. Problems such as low accuracy, to achieve the effect of improving accuracy, avoiding jitter, and avoiding negligent errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

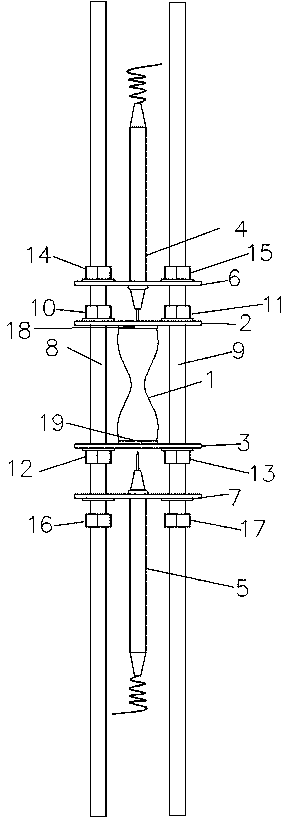

[0031] The invention discloses a micro-resistance measuring jig device for detecting metal material damage and a use method thereof, which are used for measuring the resistance change of a test piece in a fatigue damage test and characterizing the damage evolution process of the test piece.

[0032] Step 1. Place the test piece axially between the upper test piece fixing piece 2 and the lower test piece fixing piece 3. The centers of the two ends of the test piece are respectively aligned with the center positions of the upper insulating gasket 18 and the lower insulating gasket 19, Rotate the nuts 10, 11, 12, and 13 of the specimen fixing piece, so that the upper specimen fixing piece 2 and the lower specimen fixing piece 3 slowly move closer until the upper specimen fixing piece 2 and the lower specimen fixing piece 3 clamp the specimen. Hold and fix, and ensure that the central axis of the test piece 1, the connection line of the center through hole of the upper test piece f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com