Optical film and display device

An optical film, bottom surface technology, applied in optics, optical components, instruments, etc., can solve the problems of wear resistance and high optical gain of optical films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

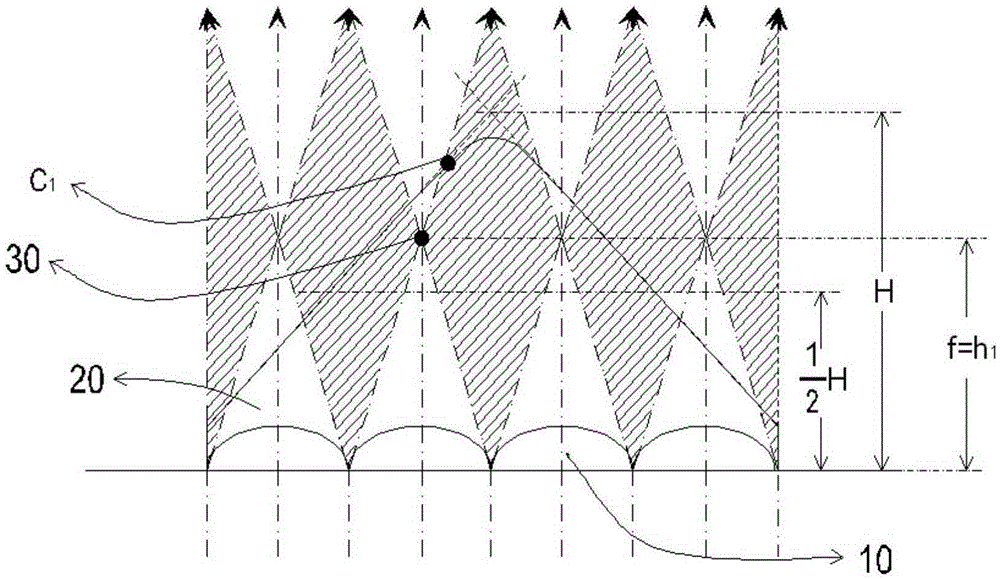

[0045] The optical film provided in this embodiment includes:

[0046] The lens layer has a bottom surface with a planar structure and is composed of a microlens array. The microlens array includes a plurality of lens structures arranged along the first direction. The lens structure is a plano-convex lens, the radius of curvature of the lens surface is r=15 μm, and the refractive index of the lens layer is n 1 =1.65, and the first direction is parallel to the bottom surface;

[0047] A prism layer, the prism layer is arranged on the lens layer away from the bottom surface, the prism layer is composed of a microprism array, the microprism array includes a plurality of prism structures arranged along the first direction, the refractive index of the prism layer is n 2 =1.35, the vertical distance H=28 μm between the intersection line of the extended surface of the side of the prism structure and the bottom surface, and the top angle of the prism structure is a rounded corner, and...

Embodiment 2

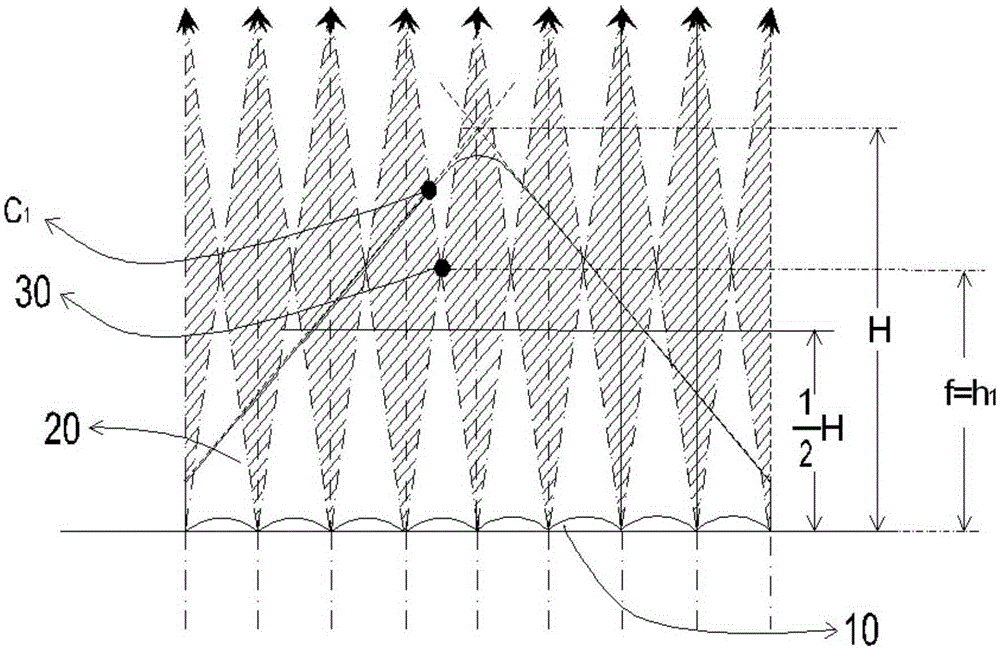

[0050] The optical film provided in this embodiment includes:

[0051] The lens layer has a bottom surface with a planar structure and is composed of a microlens array. The microlens array includes a plurality of lens structures arranged along the first direction. The lens structure is a plano-convex lens, the radius of curvature of the lens surface is r=9 μm, and the refractive index of the lens layer is n 1 =1.65, and the first direction is parallel to the bottom surface;

[0052] A prism layer, the prism layer is arranged on the lens layer away from the bottom surface, the prism layer is composed of a microprism array, the microprism array includes a plurality of prism structures arranged along the first direction, the refractive index of the prism layer is n 2 =1.35, the vertical distance H=28 μm between the intersection line of the extended surface of the side of the prism structure and the bottom surface, and the top angle of the prism structure is a rounded corner, and ...

Embodiment 3

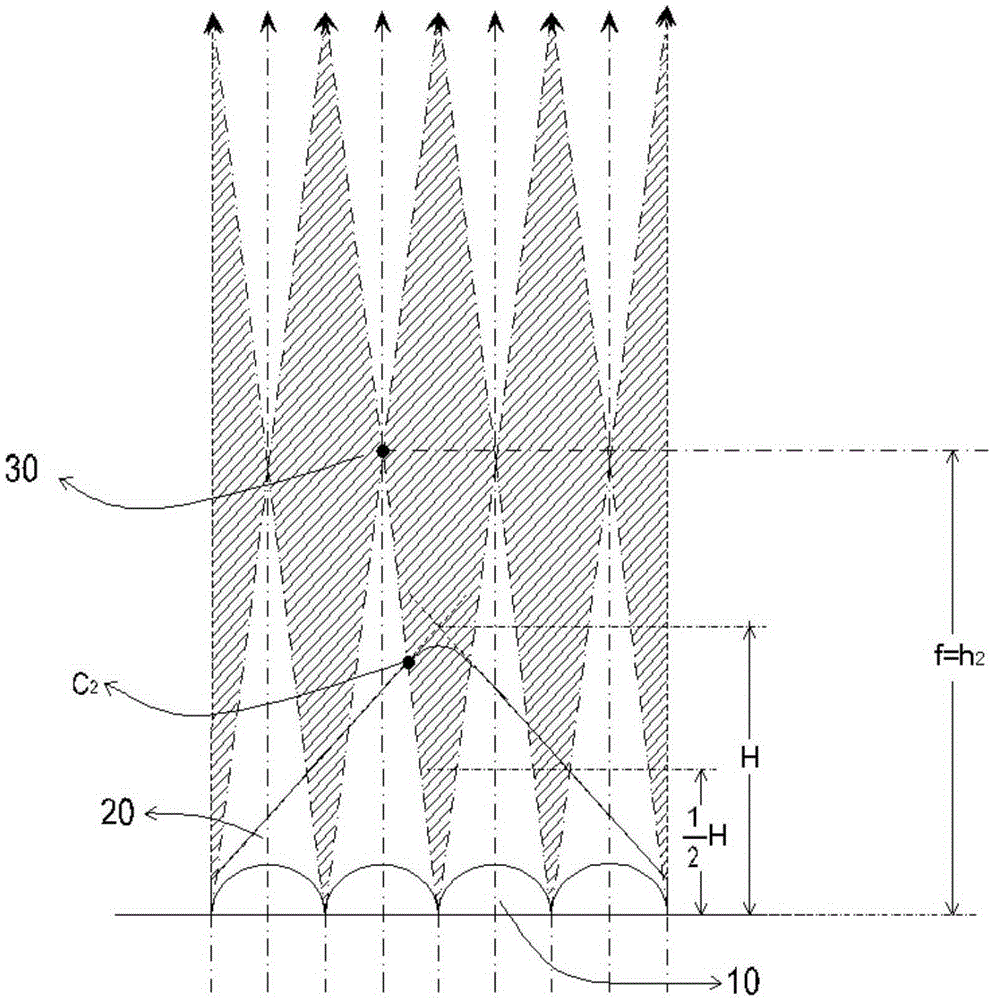

[0055] The optical film provided in this embodiment includes:

[0056] The lens layer has a bottom surface with a planar structure and is composed of a microlens array. The microlens array includes a plurality of lens structures arranged along the first direction. The lens structure is a plano-convex lens, the radius of curvature of the lens surface is r=6 μm, and the refractive index of the lens layer is n 1 =1.65, and the first direction is parallel to the bottom surface;

[0057] A prism layer, the prism layer is arranged on the lens layer away from the bottom surface, the prism layer is composed of a microprism array, the microprism array includes a plurality of prism structures arranged along the first direction, the refractive index of the prism layer is n 2 =1.35, the vertical distance H=28 μm between the intersection line of the extended surface of the side of the prism structure and the bottom surface, and the top angle of the prism structure is a rounded corner, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com