production system

A production system and product technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problem of complex change operation and achieve the effect of easy change operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0033] (Structure of production system)

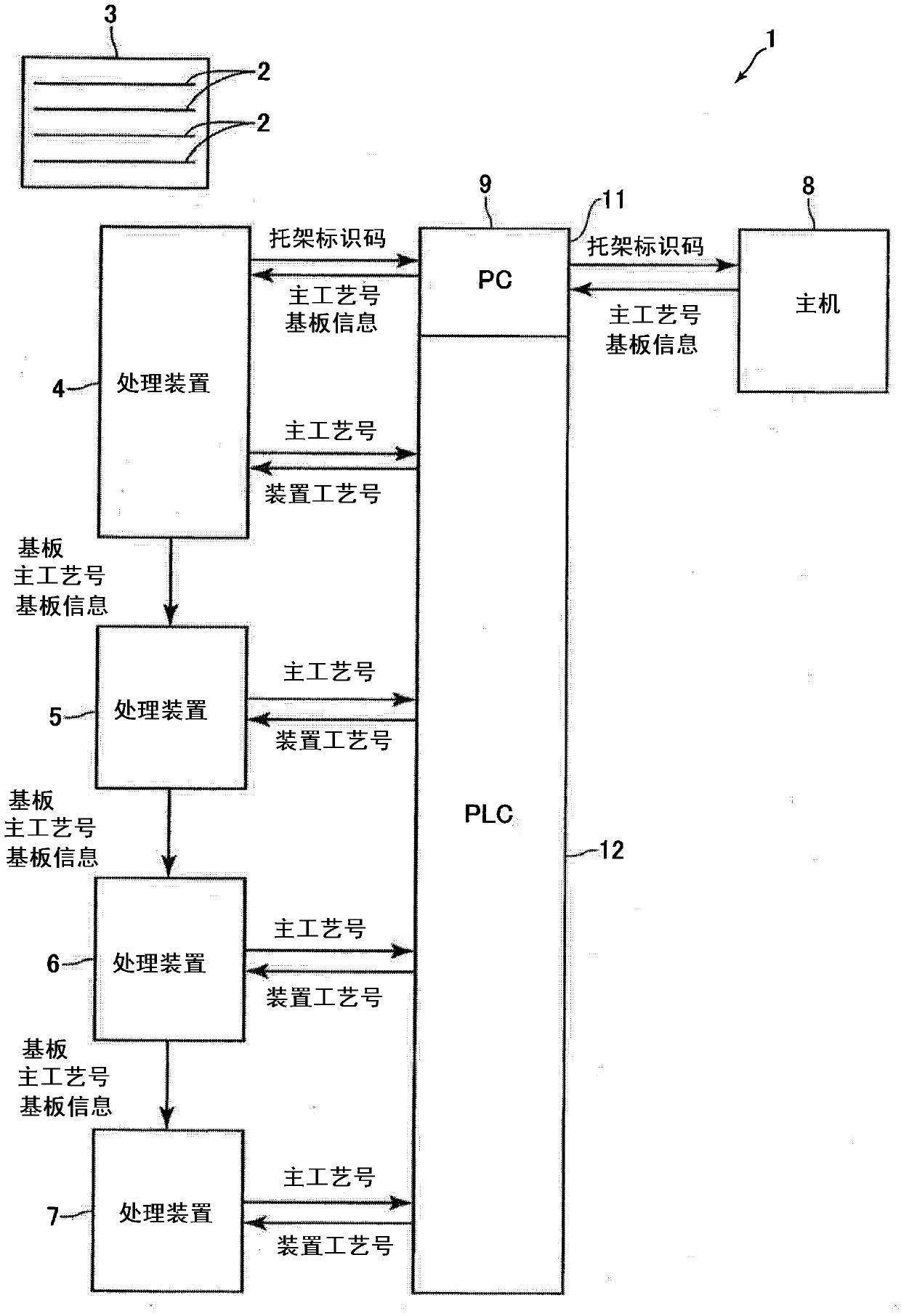

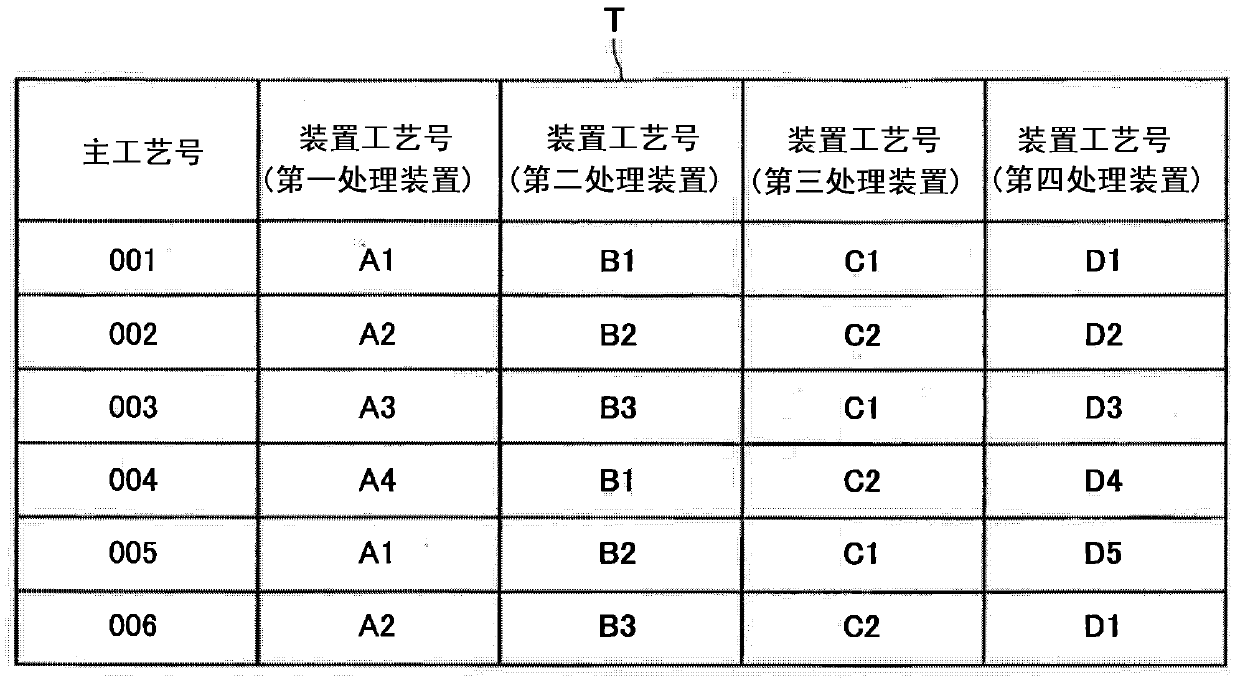

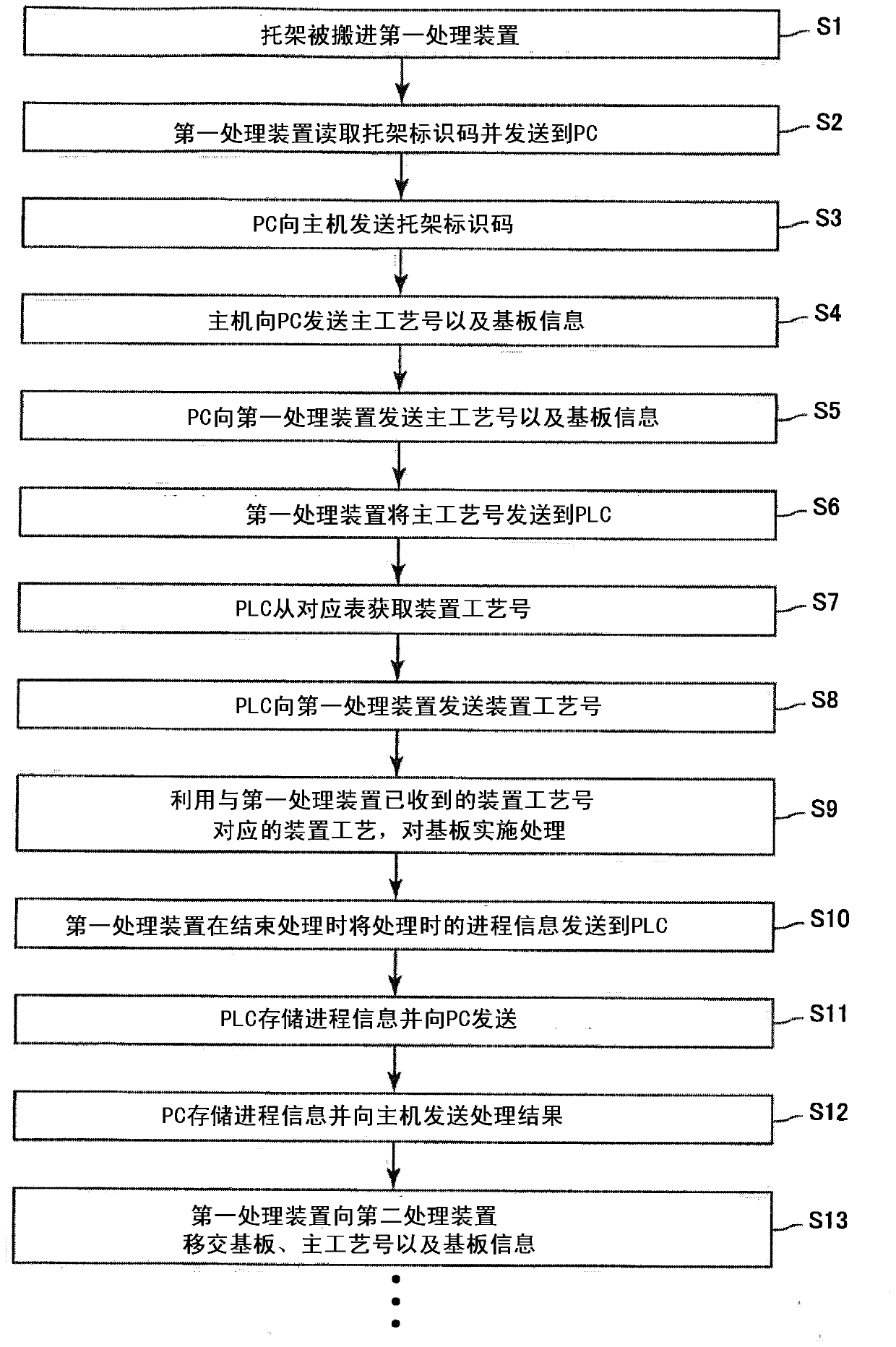

[0034] figure 1 It is a block diagram for explaining the schematic structure of the production system 1 which concerns on embodiment of this invention. figure 2 For description stored in figure 1 A diagram of the correspondence table T of the programmable logic controller 12 shown.

[0035] The production system 1 of the present embodiment is a system for producing various products by performing predetermined processing on objects to be processed. Specifically, the production system 1 of this embodiment is a system for performing predetermined processing on a substrate 2 as an object to be processed to produce various types of semiconductors as products. The production system 1 has: a bracket 3 for storing a plurality of substrates 2; a plurality of processing devices 4 to 7 for performing prescribed processing on the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com