Structure and assembly method of lithium polymer battery

A lithium polymer battery and cell technology, which is applied to battery pack components, structural parts, non-aqueous electrolyte storage batteries, etc., can solve the performance and safety hazards of the cell, damage the sealing area of the cell, and easily break the cell pole. ear and other problems, to achieve the effect of being conducive to manual operation, avoiding excessive contact, and increasing the probability of damaging the battery core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

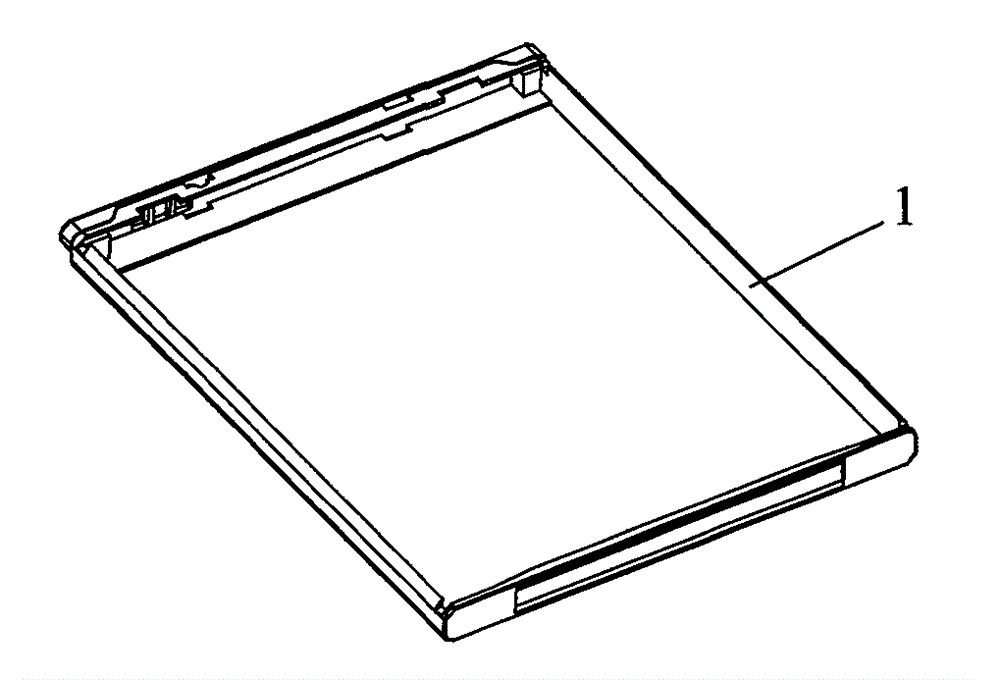

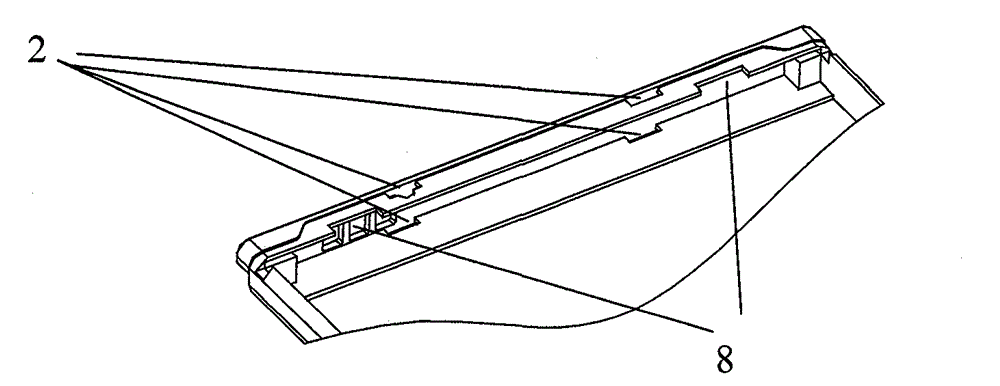

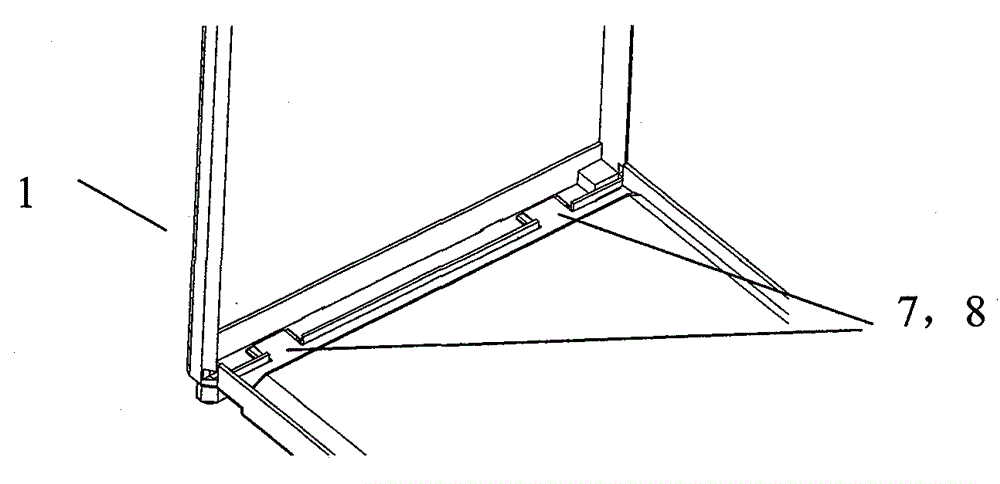

[0025] The structure of lithium polymer battery of the present invention is referring to appendix Figure 1-7 , including the plastic frame housing 1 (see figure 1 ), protective plate 3 (see Figure 4 ) and cell 6 (see Figure 5 ); the shape of the shell 1 is a frame structure with four-sided glue positions, and the effect of the shell is to fix the electric core 6 and the protective plate, insulate and form the main frame of the battery; the end seal of the electric core is provided with Positive and negative pole ears 7, said protective plate is a strip-shaped protective plate, and its width direction is provided with four trapezoidal buckles 4 protruding outwards for fixing to the plastic shell, and its surface is provided with for connecting with the electric The core realizes two rectangular nickel blocks 5 connected by spot welding; the end of the pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap