A shell centrifuge for lithium battery production

A centrifuge and lithium battery technology, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problem that the efficiency of battery cores entering the shell needs to be improved, affecting the working efficiency of the centrifugal turntable, and the efficiency of battery cores entering the shell is low To achieve the effect of improving the transfer speed and utilization rate, improving the efficiency of entering the shell, and saving the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

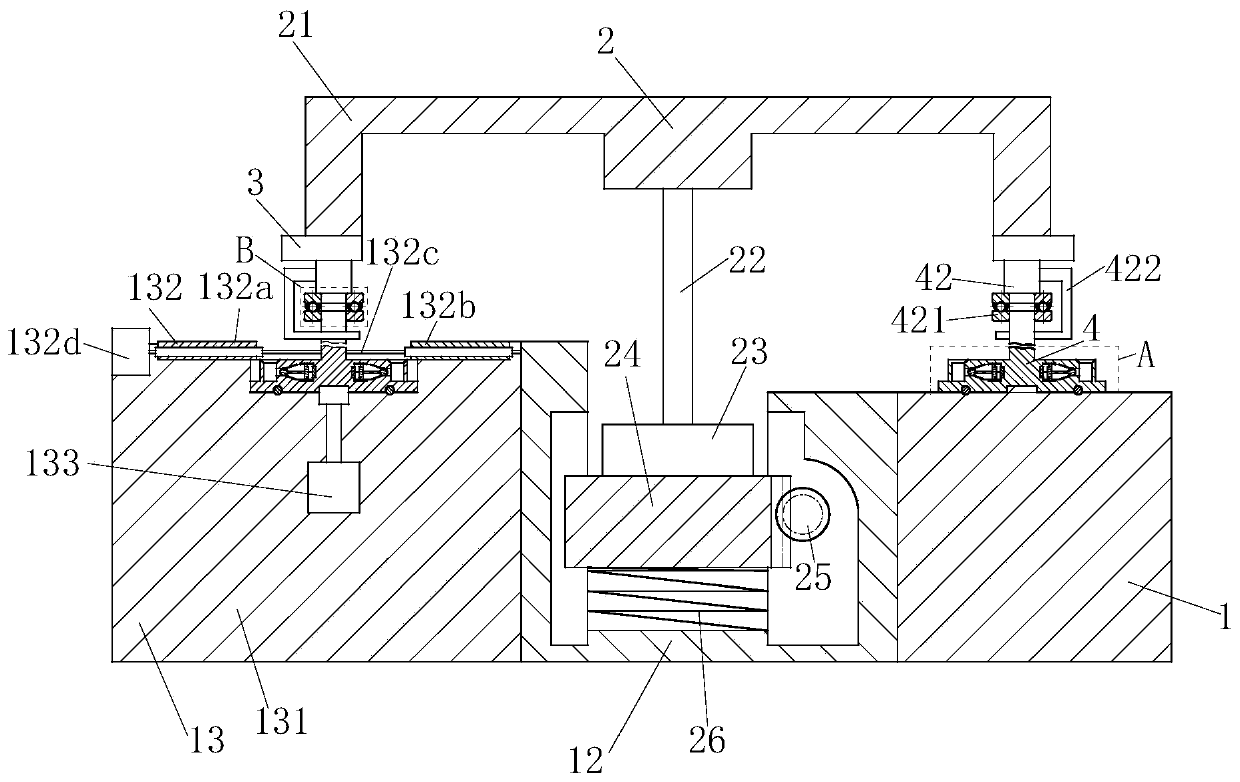

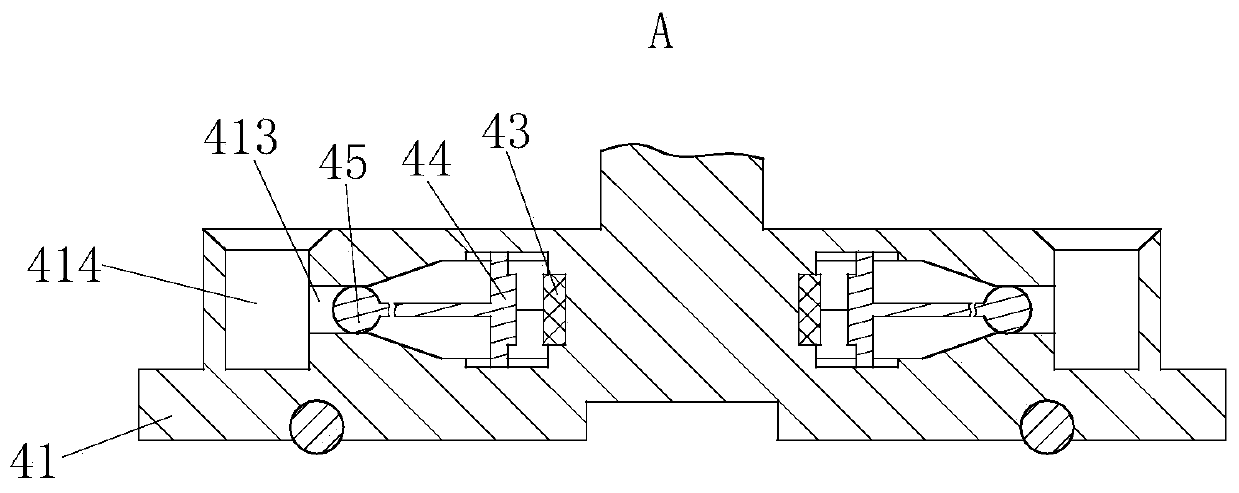

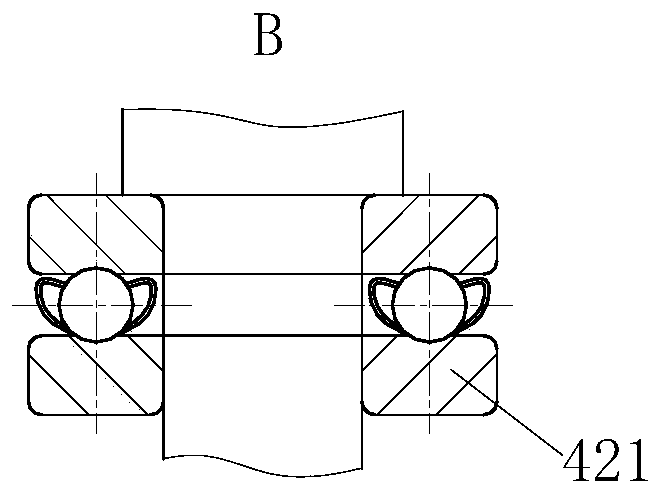

[0028] Such as Figure 1 to Figure 9 As shown, a shell centrifuge for lithium battery production includes a worktable 1, a rotating lifting unit 2, a clamping unit 3 and a centrifugal disc 4. The working table 1 includes an arc-shaped flow table 11, a lifting table 12 and a rotating Table 13, the rotating table 13 is located at the arc gap of the arc-shaped flow table 11, the rotating table 13 is used to drive the centrifugal disc 4 to rotate, the arc-shaped flow table 11 includes the input end 111 and the take-out end 112 at the two ends of the arc-shaped flow table 11, The arc-shaped flow table 11 is used to move the empty centrifugal disc 4 from the take-out end 112 to the put-in end 111, the lifting table 12 is located between the arc-shaped f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap