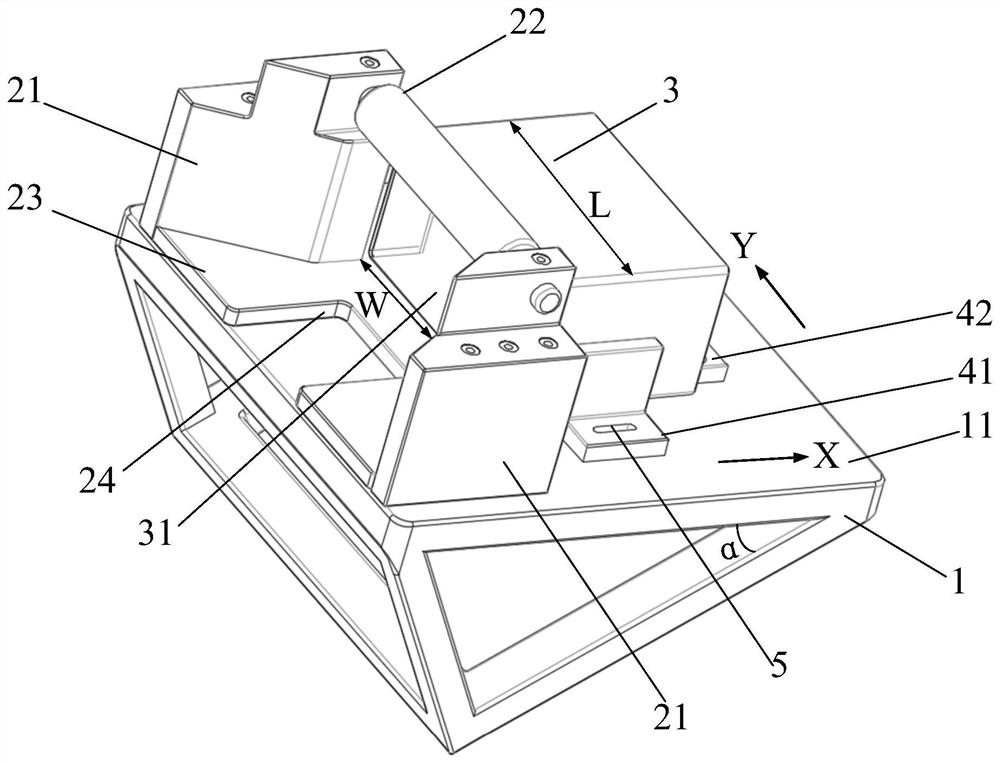

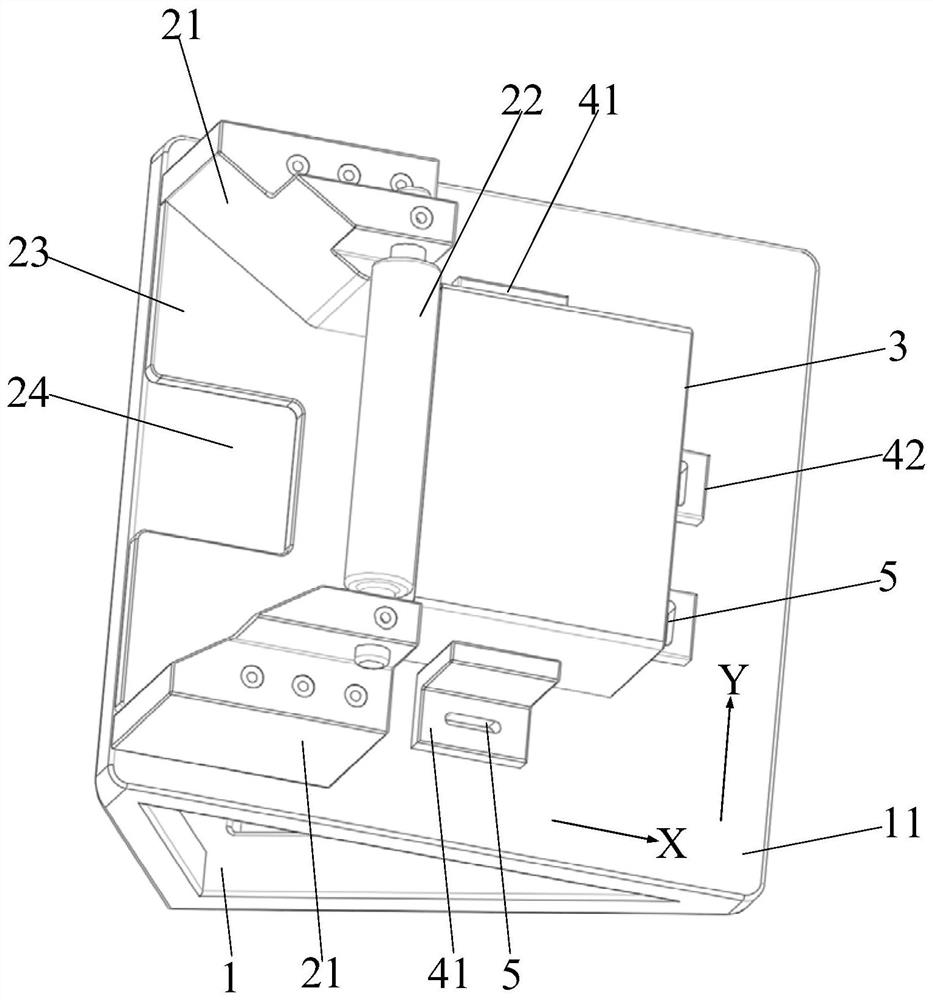

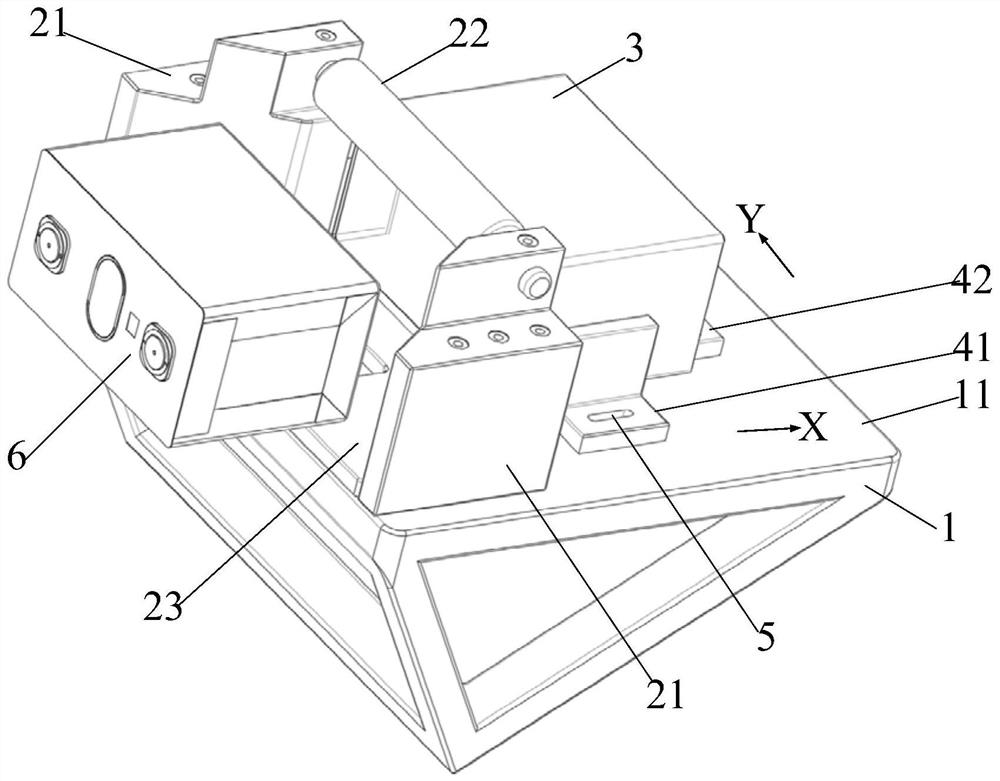

Battery cell in-shell tool jig

A technology of tooling fixtures and battery cells, which is applied to lithium batteries, battery assembly machines, and secondary battery manufacturing. It can solve the problems of Mylar being easily scratched at the mouth of the shell, manual insertion of batteries into the shell, and high cost of automation equipment. Reduce the difficulty of entering the shell, reduce the number of manual touches on the battery cell, and make the shelling operation simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description provides specific application scenarios and requirements of the application, with the purpose of enabling those skilled in the art to manufacture and use the contents of the application. Various local modifications to the disclosed embodiments will be readily apparent to those skilled in the art, and the general principles defined herein may be applied to other embodiments and embodiments without departing from the spirit and scope of the application. application. Thus, the application is not limited to the embodiments shown, but is to be accorded the widest scope consistent with the claims.

[0025] The terminology used herein is for the purpose of describing particular example embodiments only and is not intended to be limiting. For example, as used herein, the singular forms "a", "an" and "the" may also include the plural forms unless the context clearly dictates otherwise. When used in the embodiments of the present application, the terms...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap