Battery cell structure wrapped with inner insulating film and preparation method of battery cell structure

A technology of internal insulation and batteries, applied in structural parts, electrolyte battery manufacturing, circuits, etc., can solve problems such as poor contact and side reactions, achieve the effects of reducing expansion force, reducing thickness, and improving shell entry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] In order to clearly and completely describe the technical solution of the present invention and its specific working process, with reference to the accompanying drawings, the specific embodiments of the present invention are as follows:

[0031] In the description of this specification, description with reference to the terms "one embodiment," "some embodiments," "example," "specific example," or "some examples", etc., mean specific features described in connection with the embodiment or example , structure, material or feature is included in at least one embodiment or example of the present invention. In this specification, schematic representations of the above terms are not necessarily directed to the same embodiment or example. Furthermore, the particular features, structures, materials or characteristics described may be combined in any suitable manner in any one or more embodiments or examples. Furthermore, those skilled in the art may combine and combine the dif...

Embodiment 1

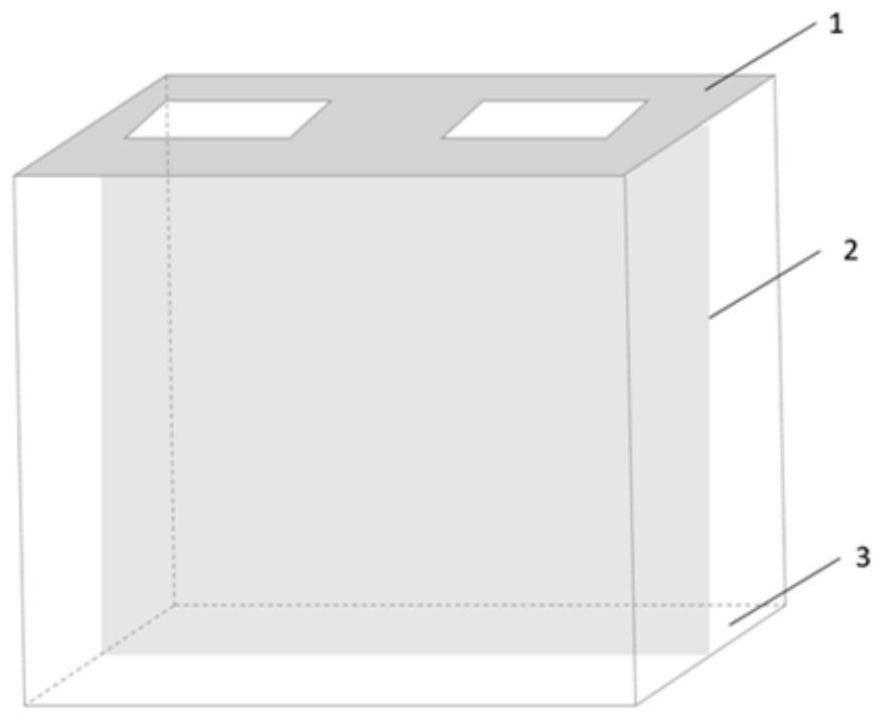

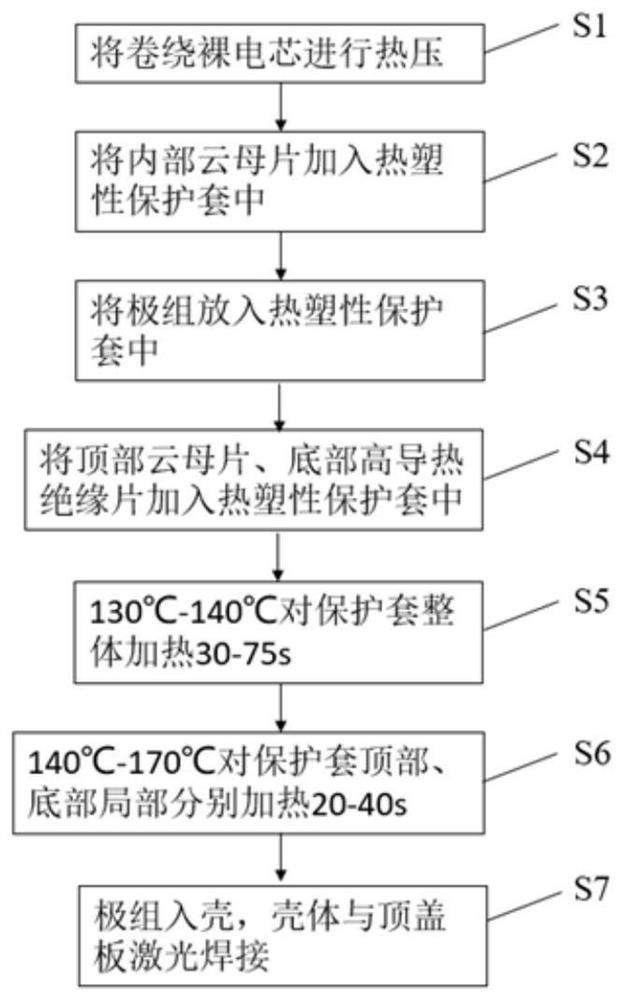

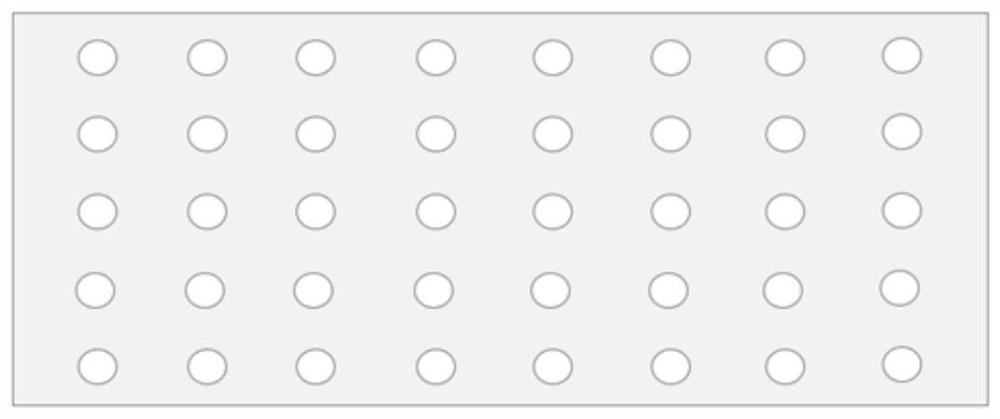

[0050] In this embodiment, a cell structure wrapped with an inner insulating film includes a bare cell and an inner insulating film protective cover wrapped thereon. The thickness of the bare cell is 14.40mm; after the two bare cells are connected in parallel, they are welded together with the battery cover by ultrasonic welding and fixed with tape; A flame-retardant mica patch is arranged between the thermoplastic inner insulating film protective sleeve and the bare cell, and the flame-retardant mica patch is in contact with the bottom and side of the thermoplastic inner insulating film protective sleeve, and is bonded by glue; The thickness of the flame-retardant mica patch on the side of the cell is 0.2mm, the thickness of the flame-retardant mica patch at the top of the bare cell is 0.5mm, and the thickness of the flame-retardant mica patch at the bottom of the cell is 1mm; The number of flame-retardant mica patches located on the side of the bare cell is determined accord...

Embodiment 2

[0058] In this embodiment, a cell structure wrapped with an inner insulating film includes a bare cell and an inner insulating film protective cover wrapped thereon. The thickness of the bare cell is 14.40mm; after the two bare cells are connected in parallel, they are welded together with the battery cover by ultrasonic welding and fixed with tape; A flame-retardant mica patch is arranged between the thermoplastic inner insulating film protective sleeve and the bare cell, and the flame-retardant mica patch is in contact with the bottom and side of the thermoplastic inner insulating film protective sleeve, and is bonded by glue; The thickness of the flame-retardant mica patch on the side of the cell is 0.2mm, the thickness of the flame-retardant mica patch at the top of the bare cell is 0.5mm, and the thickness of the flame-retardant mica patch at the bottom of the cell is 1mm; The number of flame-retardant mica patches located on the side of the bare cell is determined accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap