Temperature control device for electric vehicle and electric vehicle

A temperature control device, electric vehicle technology, applied in electric vehicles, battery/fuel cell control devices, vehicle energy storage, etc. Thermal runaway problem, small difference in heating power, and the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

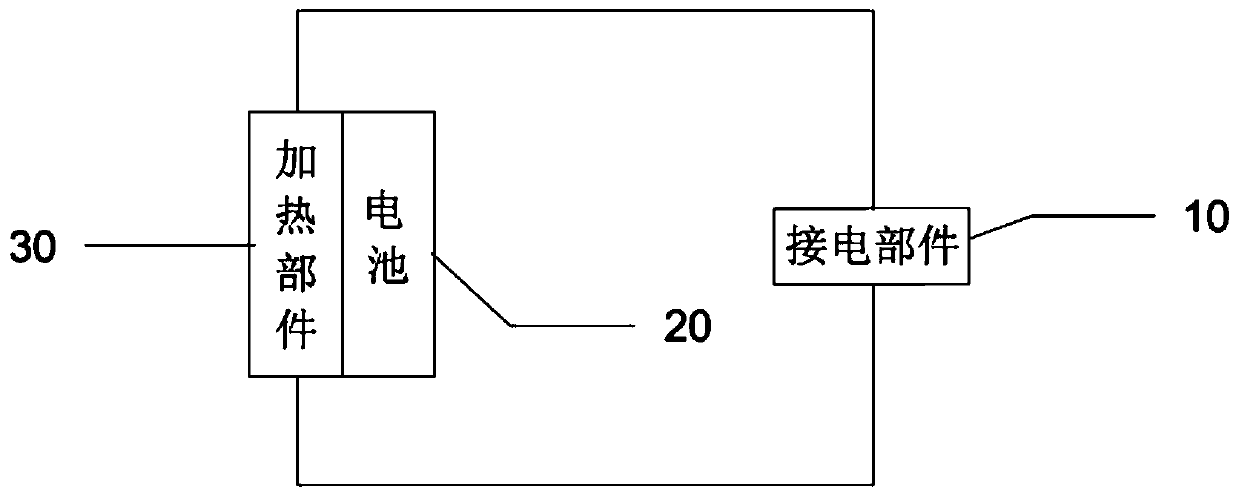

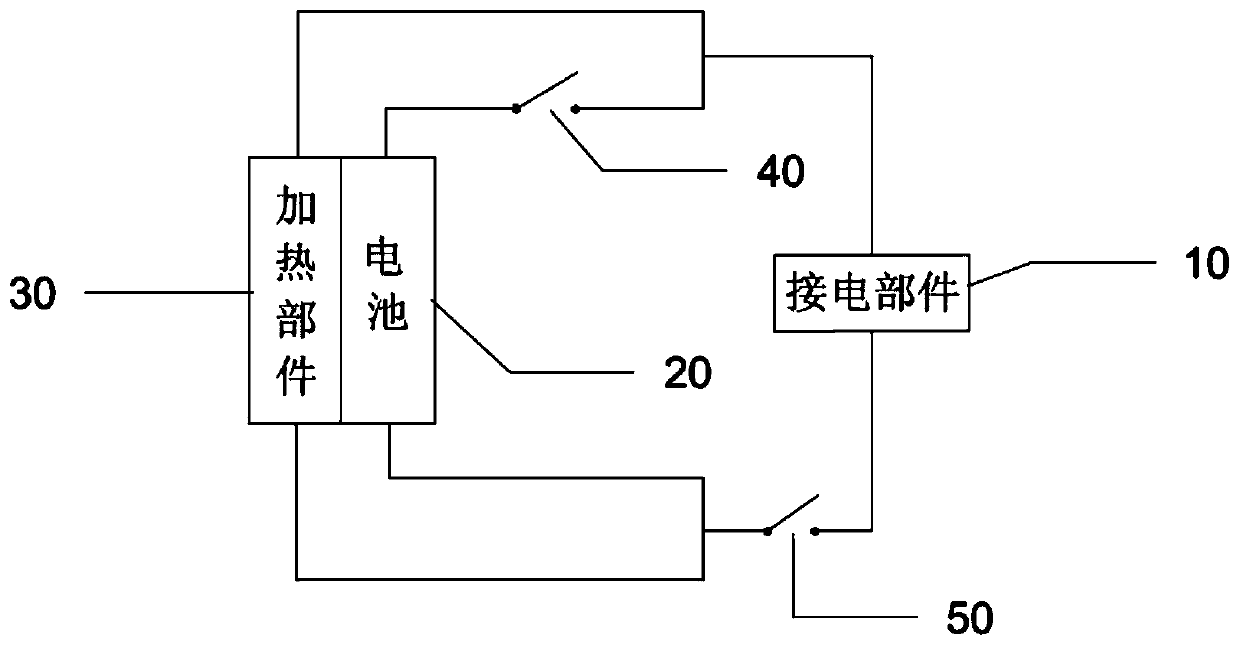

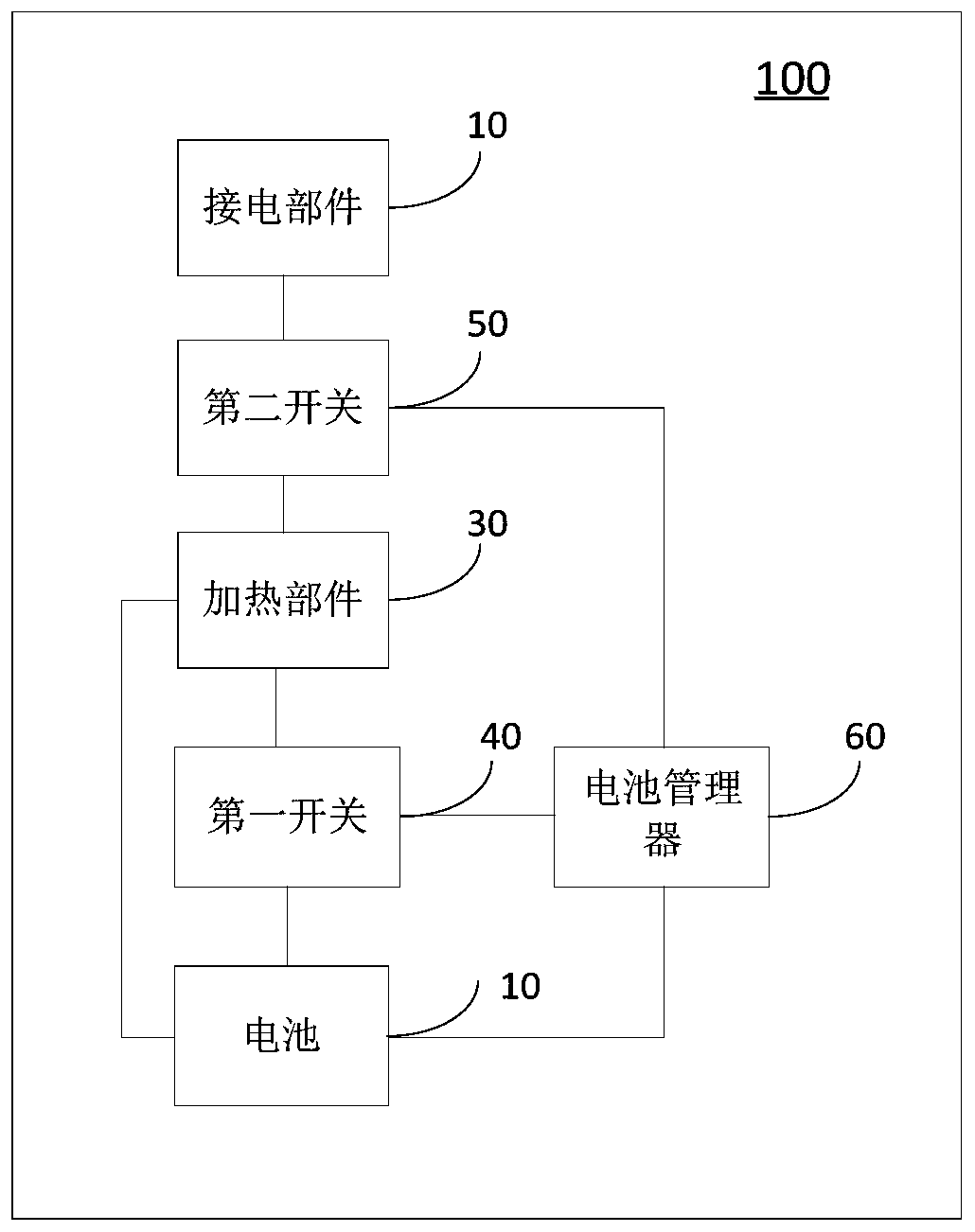

[0031] see figure 1 A temperature control device 100 for an electric vehicle of the present invention includes: a power connection part 10, a battery 20 and a heating part 30, the battery 20 is installed in the electric vehicle and constitutes its power source; the power connection part 10 is used To connect to an external power supply other than the battery 20; several heating components 30 connected in parallel are attached to the battery 20 and electrically connected to the electrical connection component 10, which can provide heat to the battery 20 when the external power supply supplies power to the heating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com