Datum plane and hole processing clamp for tricone bit legs

A technology of three-cone and hole processing, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems such as the difficulty of ensuring the consistency of the reference hole and the uneven milling amount of the tooth palm reference surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

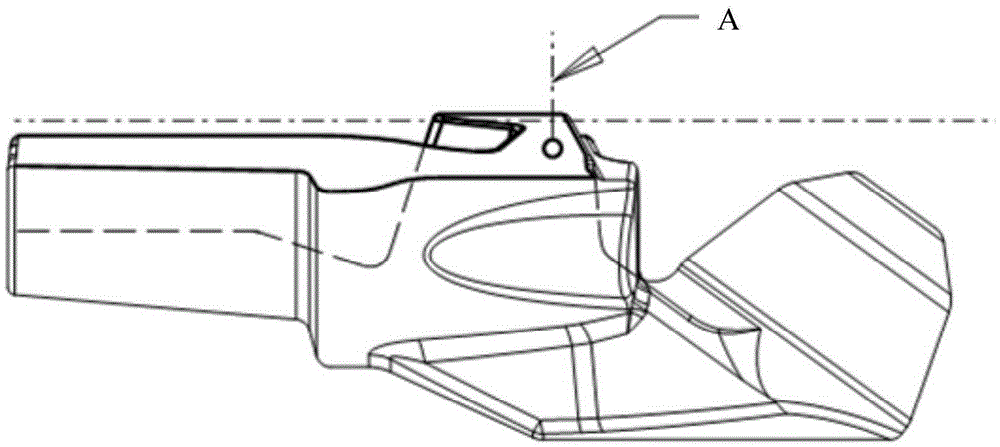

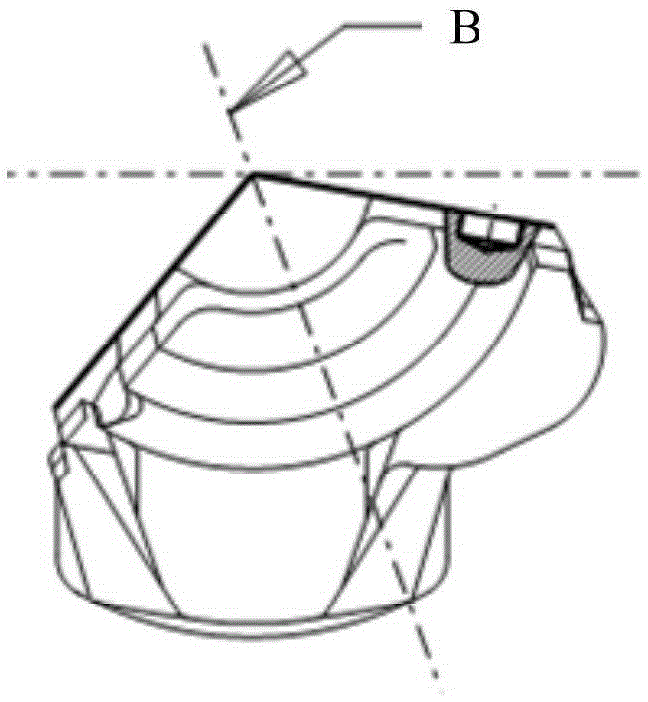

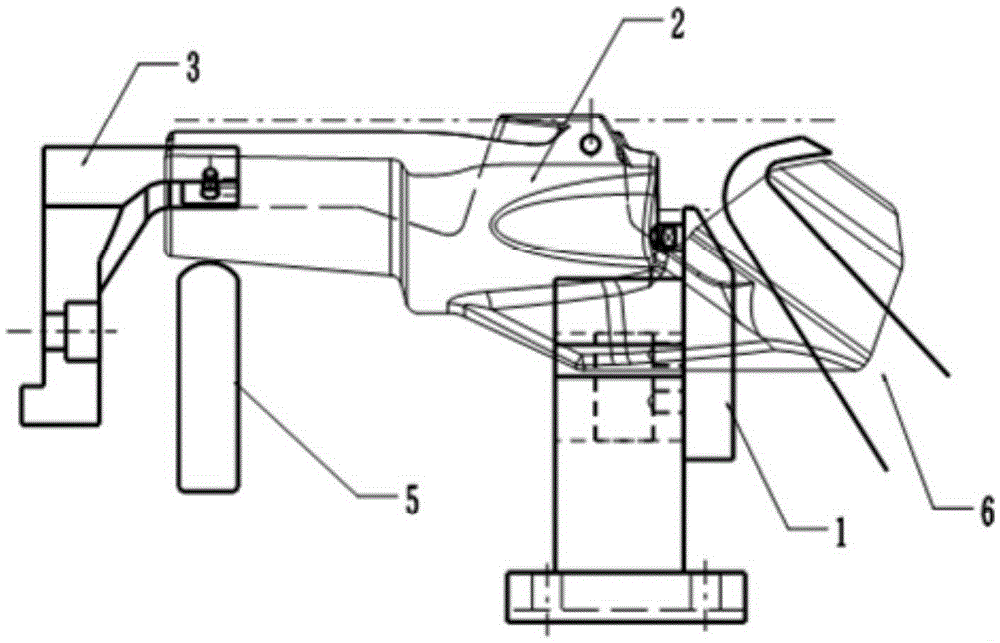

[0016] Such as Figure 2~3 As shown, the palm reference plane of the tricone bit and the hole processing fixture include the palm tip support and positioning part 4, the air jet hole positioning seat 1, the pressing block 3, the support screw 5 and the clamping arm 6, and the air jet hole positioning seat 1 and the palm tip support and positioning part 4 are arranged in front and rear relative to each other, the clamping arm 6 is set on the right side of the air jet hole positioning seat 1, the support screw 5 is set on the left side of the air jet hole positioning seat 1, and the compression block is set on the left side of the support screw 5 3. The pressure head of the compression block 3 is located above the support screw 5, and the tooth palm 2 is positioned on the support screw 5, the air jet hole positioning seat 1 and the palm tip support positioning part 4, and the air jet hole positioning seat 1 is formed to limit the tooth palm The palm tip support positioning point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com