Stone thicknessing machine

A stone and casing technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of easy offset, unstable thickness-determining mechanism, and small cutting area of the thickness-determining plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

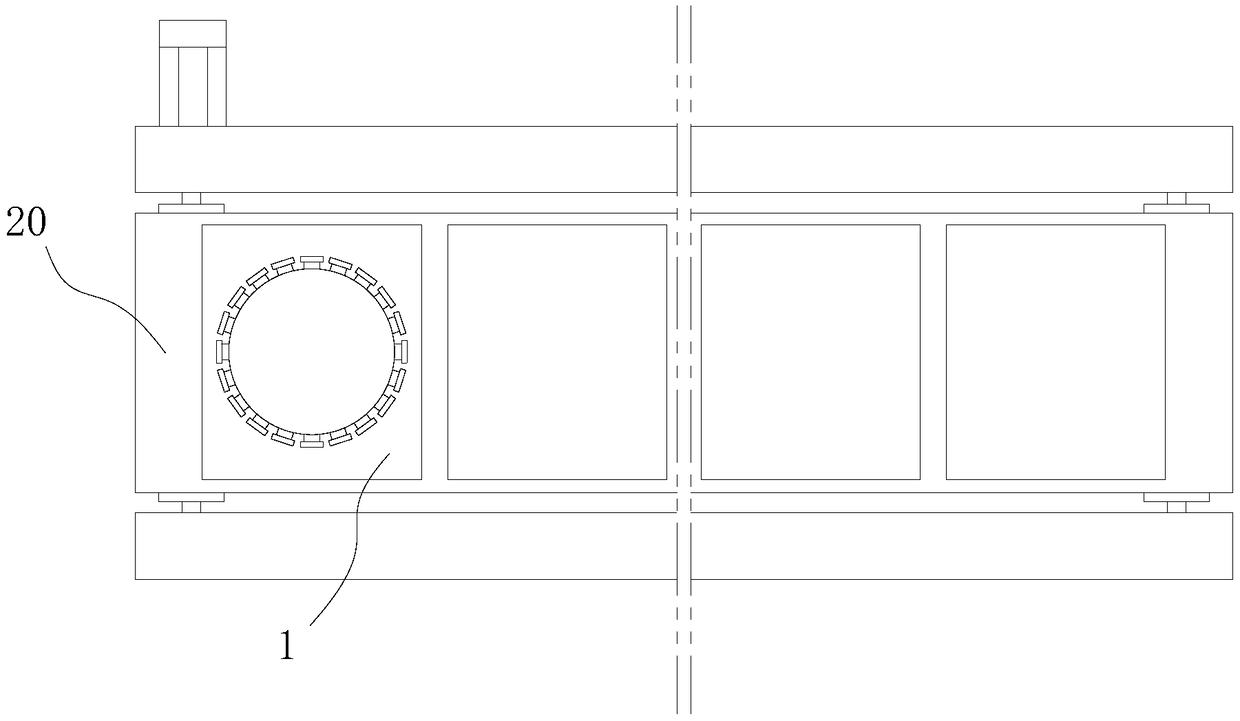

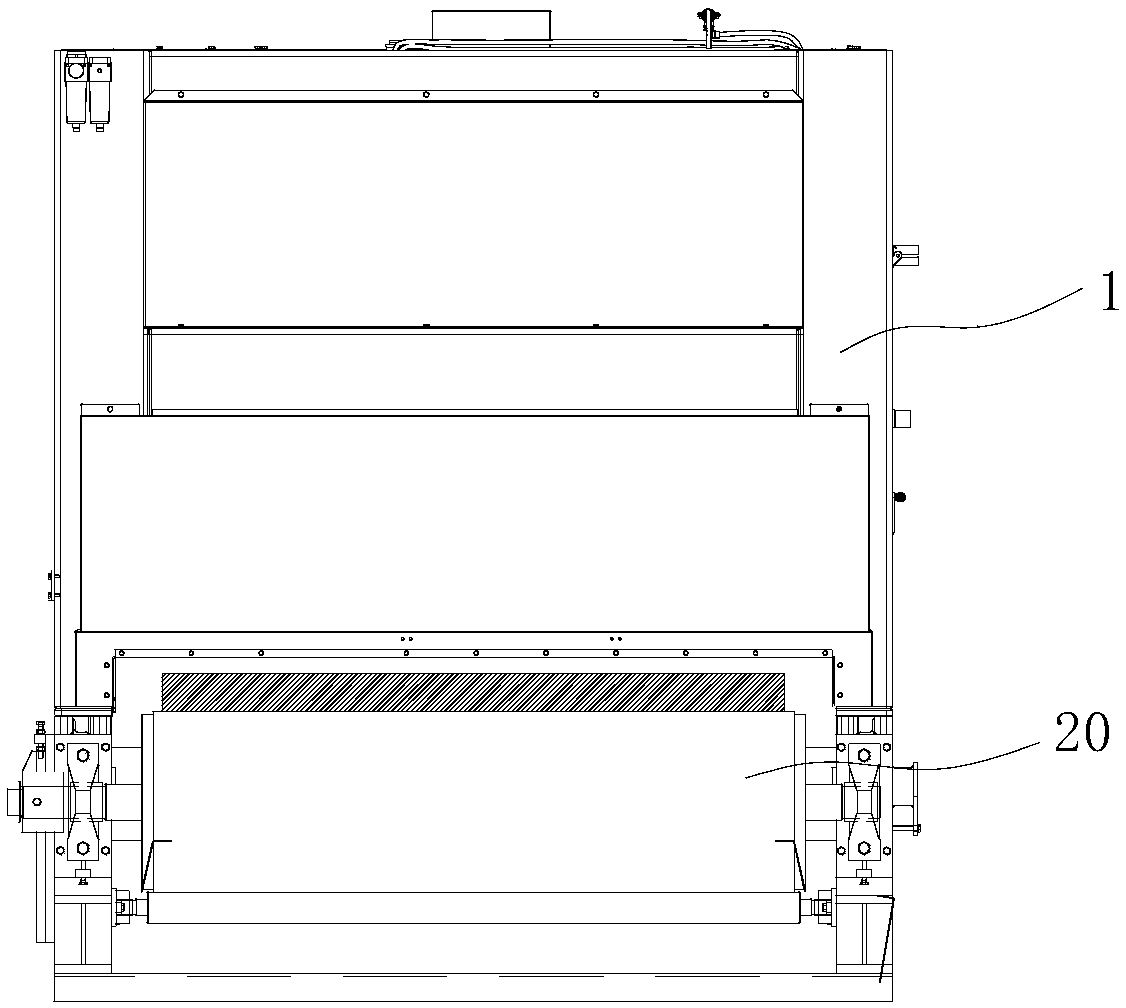

[0027] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a stone thickness-calibrating machine, which is installed on the stone milling and grinding production line. The stone milling and grinding production line mainly realizes the transshipment of stones through the conveyor belt 20. on the conveyor belt 20.

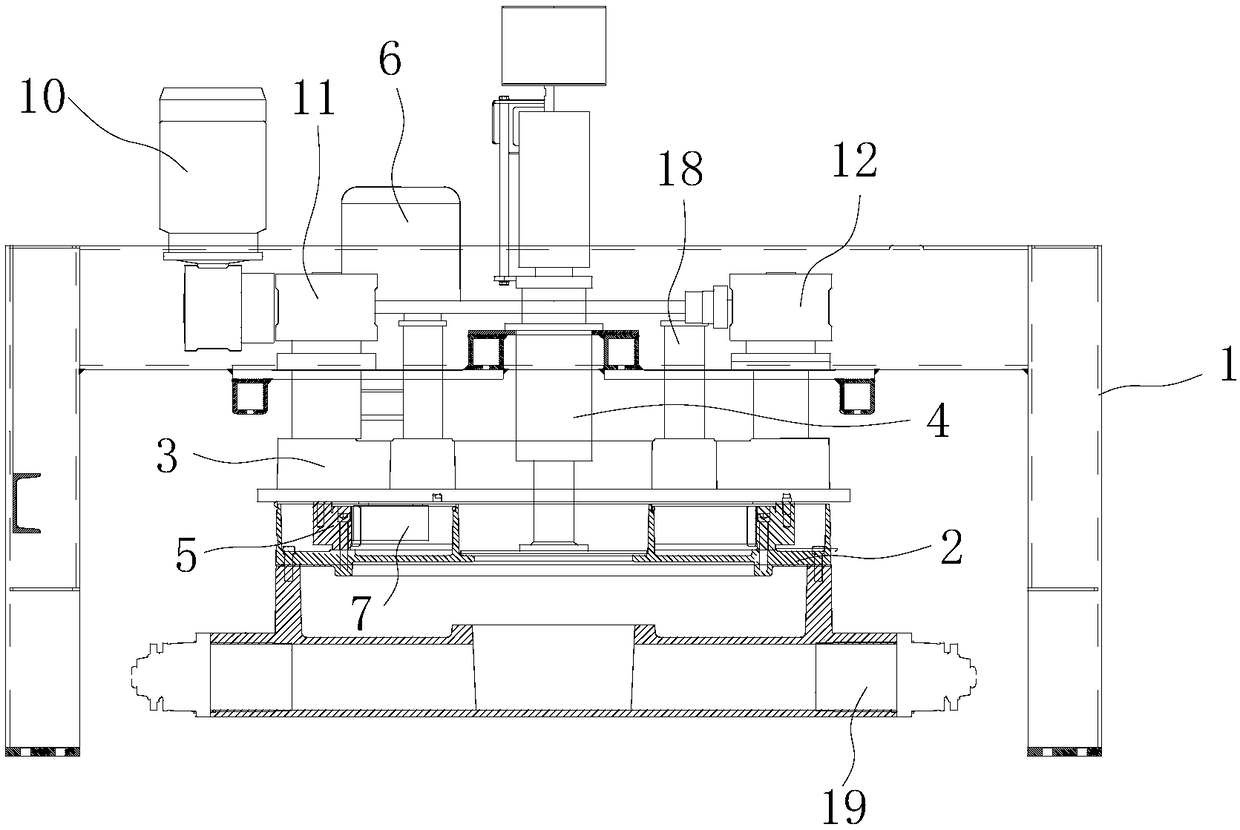

[0028] A single stone thickness gauge machine includes a casing 1, a turntable 2, a lifting platform 3, a lifting assembly, a grinding wheel motor 19 and a grinding wheel. The casing 1 is covered on the conveyor belt 20. It can play the role of isolating water mist and dust.

[0029] The turntable 2, the lifting platform 3, the lifting assembly, the grinding wheel motor 19 and the grinding wheel are all arranged in the casing 1, the lifting assembly is connected with the lifting platform 3, the lifting assembly is used to drive the lifting platform 3 to move up and down, and the turntable 2 is installed at the lower end of the lifting platform 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com