Chopping board edge milling and sanding production line and method

A production method and technology for a production line, which are applied to a cutting board edge milling and sanding production line and its production field, can solve the problems of scrapped cutting boards, cracked edges of bamboo cutting boards, low efficiency, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

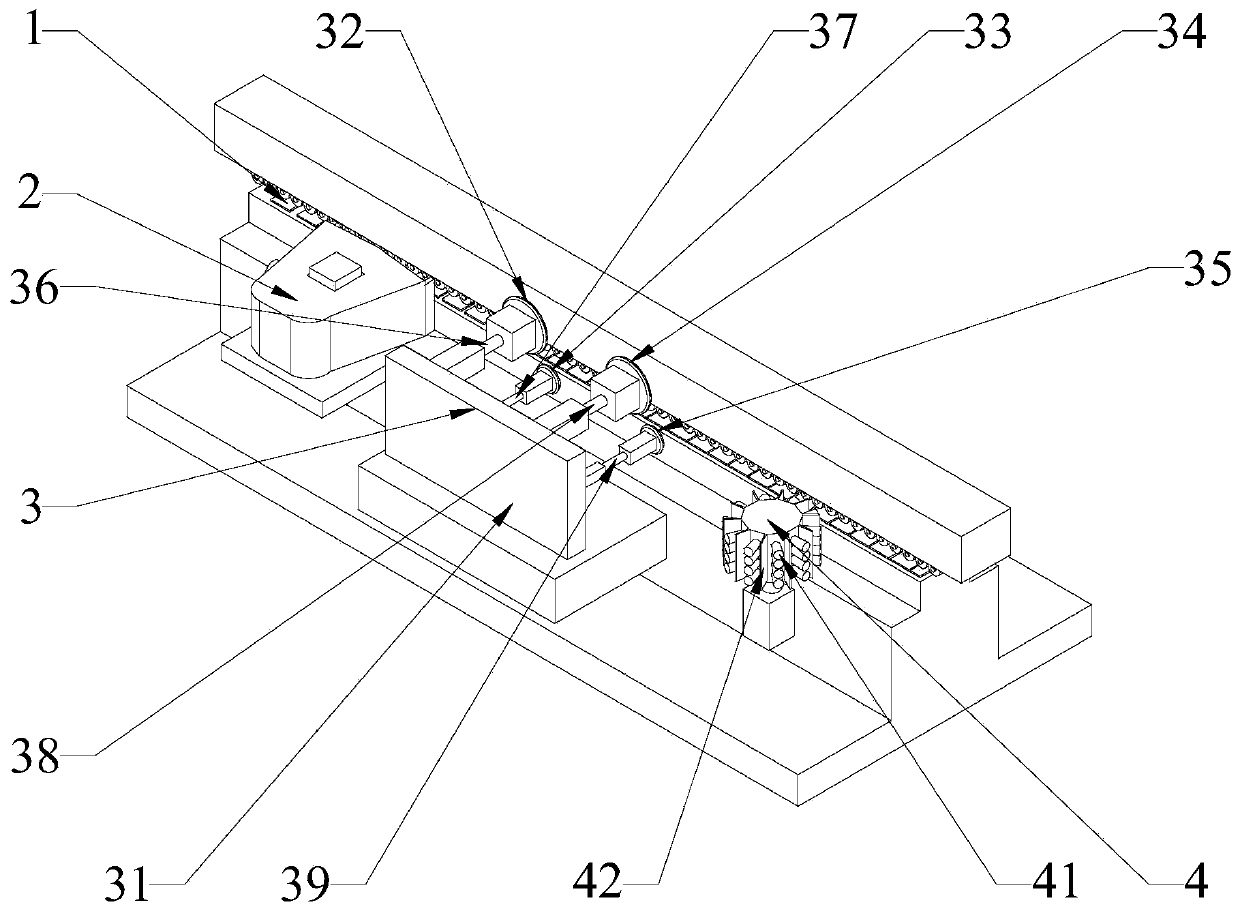

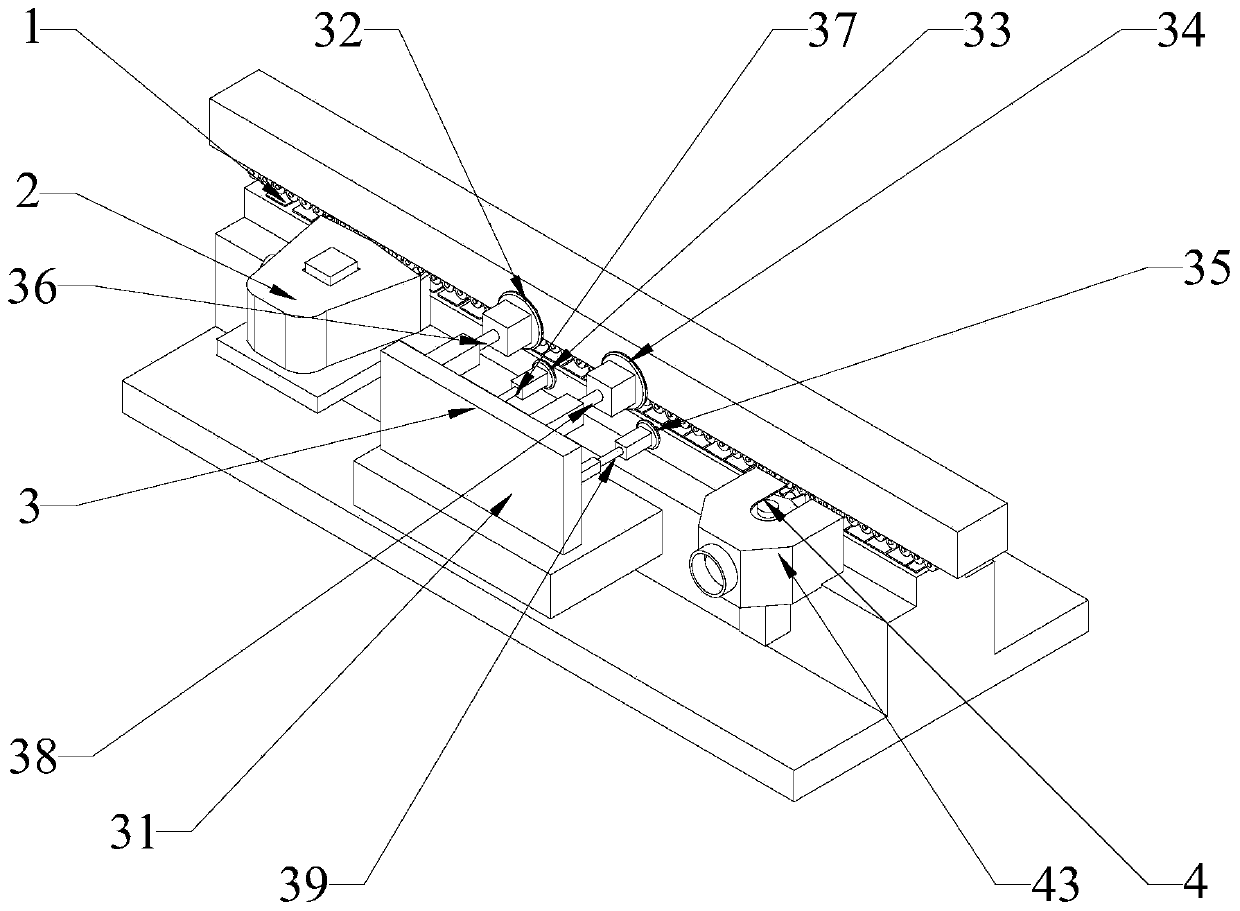

Embodiment 1

[0056] A cutting board edge milling and sanding production line, comprising a conveyor belt 1, a first sanding device 2, and an edge milling device 3; The first sanding device 2 includes a rolling abrasive belt, and the first sanding is performed by the rolling abrasive belt contacting the edge of the cutting board passing through the conveyor belt 1; the milling device 3 includes a base 31, a first Upper cutter wheel 32, the first cylinder 36, the first lower cutter wheel 33, the second cylinder 37, the second upper cutter wheel 34, the third cylinder 38 and the second upper cutter wheel 34 and the fourth cylinder 39; The upper cutter wheel 32 is connected to the base 31 through the first cylinder 36, the first lower cutter wheel 33 is connected to the base 31 through the second cylinder 37, and the second upper cutter wheel 34 is connected to the base 38 through the third cylinder 38. Seat 31, the second lower cutter wheel 35 is connected to the base 31 through the fourth cy...

Embodiment 2

[0059] A production method for edge milling and sanding of cutting boards, comprising the following steps:

[0060] Step 1: The conveyor belt 1 drives the cutting board to move forward, so that one side of the cutting board contacts the abrasive belt of the first sanding device 2, and removes the burrs on the edge of the cutting board through the friction of the abrasive belt;

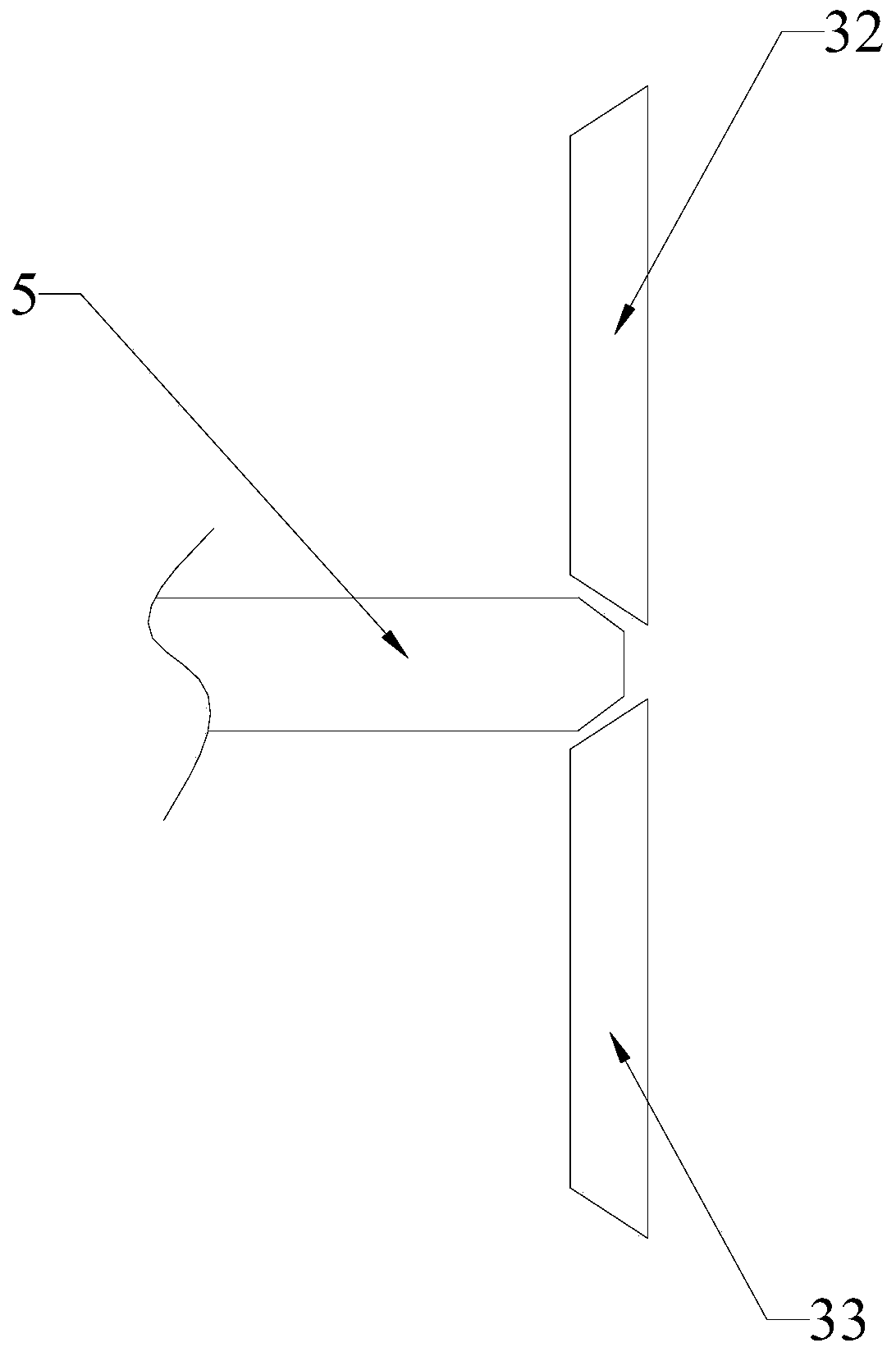

[0061] Step 2: The conveyor belt 1 continues to drive the cutting board to move forward, milling the first two-thirds of the upper edge of one side of the cutting board through the first upper cutter wheel 32; The first two-thirds of the lower edge of one side are milled;

[0062] Step 3: The conveyor belt 1 continues to drive the cutting board to move forward, and mills the rear two-thirds of the upper edge of one side of the cutting board through the second upper cutter wheel 34 in a direction opposite to that of the first upper cutter wheel 32; Carry out edge milling to the rear two-thirds of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com