An online detection method for the oblique guide sliding surface of the oblique wedge slider

A wedge slider and detection method technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of secondary alignment error, time-consuming and laborious, etc., and achieve accurate detection results and low cost of use Low, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

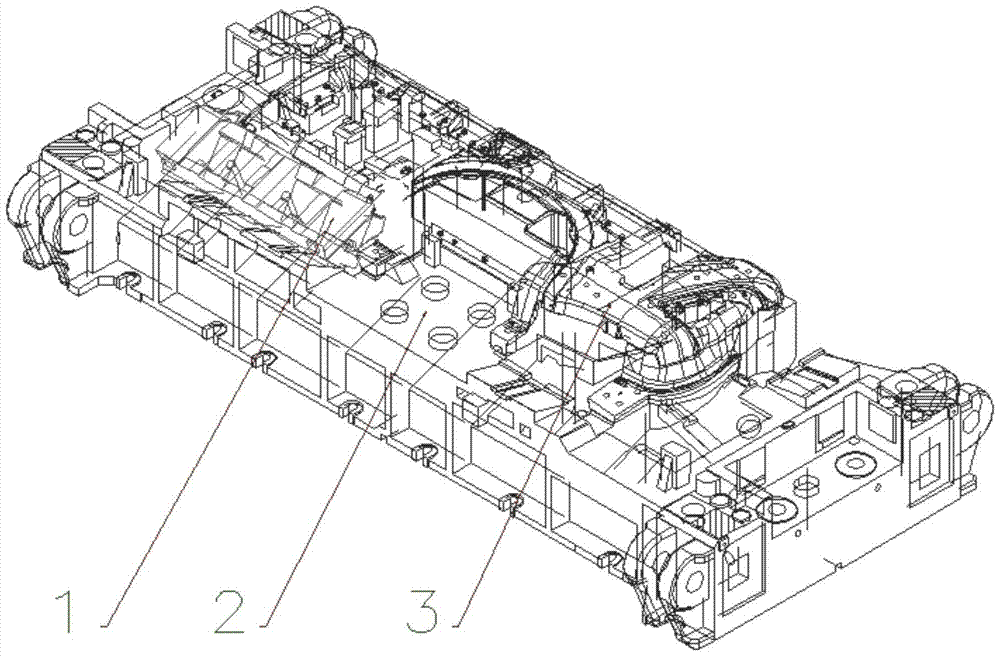

[0028] The online detection method of the oblique guide sliding surface of a wedge slider of the present invention is particularly suitable for detecting the oblique guide sliding surface of the oblique wedge slider installed in the mold, such as figure 1 The wedge slider in the trimming die of the cargo box side plate shown in . The following describes in detail the online detection method of the oblique guide sliding surface of the oblique wedge slider of the present invention.

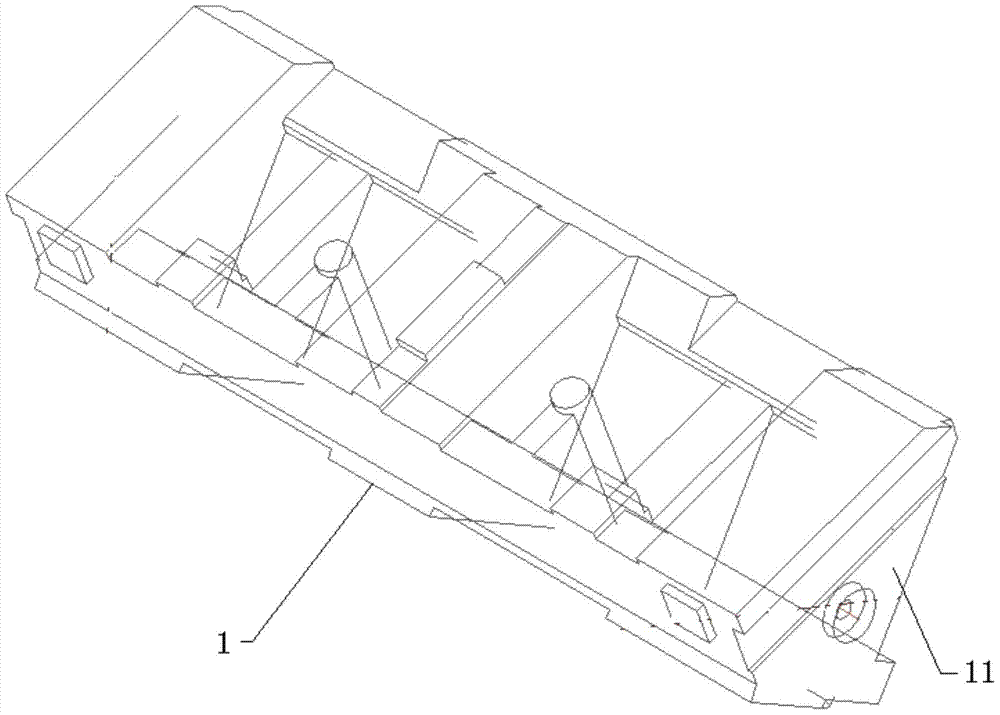

[0029] Such as Figure 2-3 As shown, the online detection method of the inclined guide sliding surface of a kind of wedge slider in this embodiment includes the following steps:

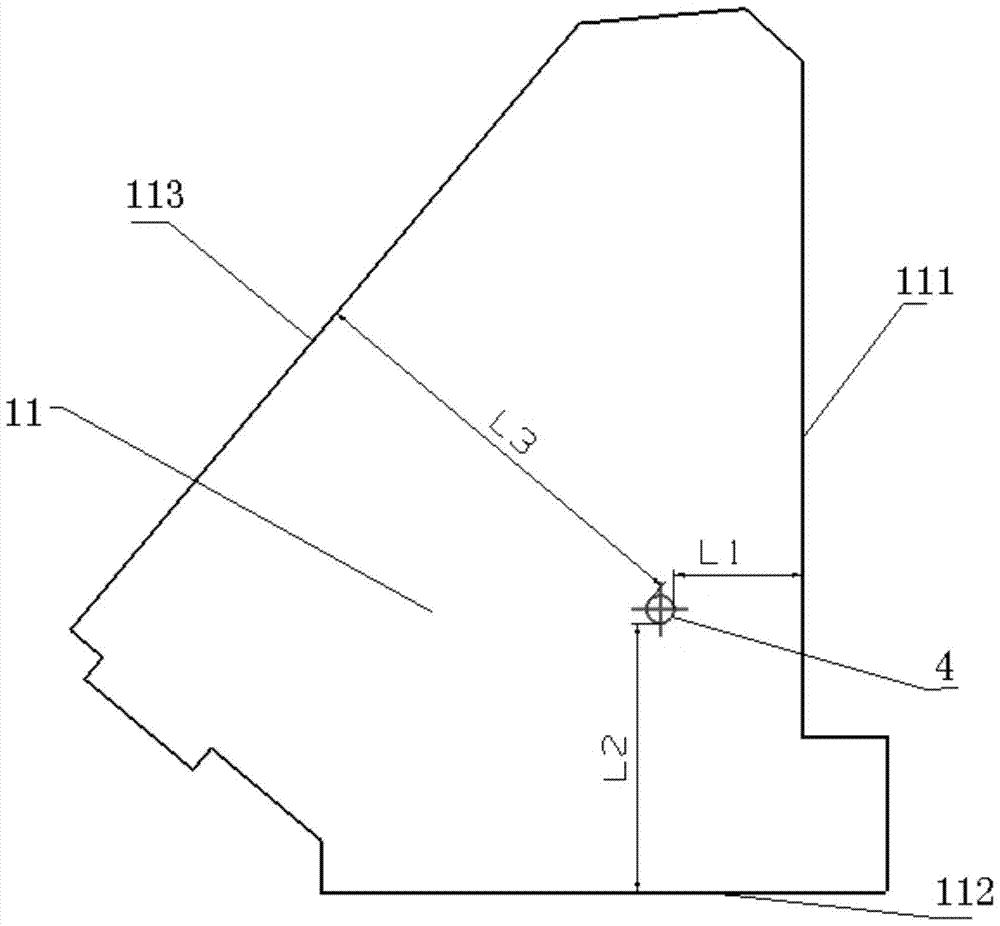

[0030] Step 1: Set a cylindrical datum on the wedge side of the wedge slider;

[0031] Step 2: Measure the distance L1 from the outer circumference of the cylindrical datum to the vertical side of the wedge-shaped side, the distance L2 to the horizontal side of the wedge-shaped side, the distance L3 to the hypotenuse of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com