Injection mould and degating method thereof

A technology for injection molds and nozzles, applied in the field of injection molds, can solve problems such as high production costs, a large amount of labor and trimming time, and low production efficiency, and achieve the effects of long service life, saving production time, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

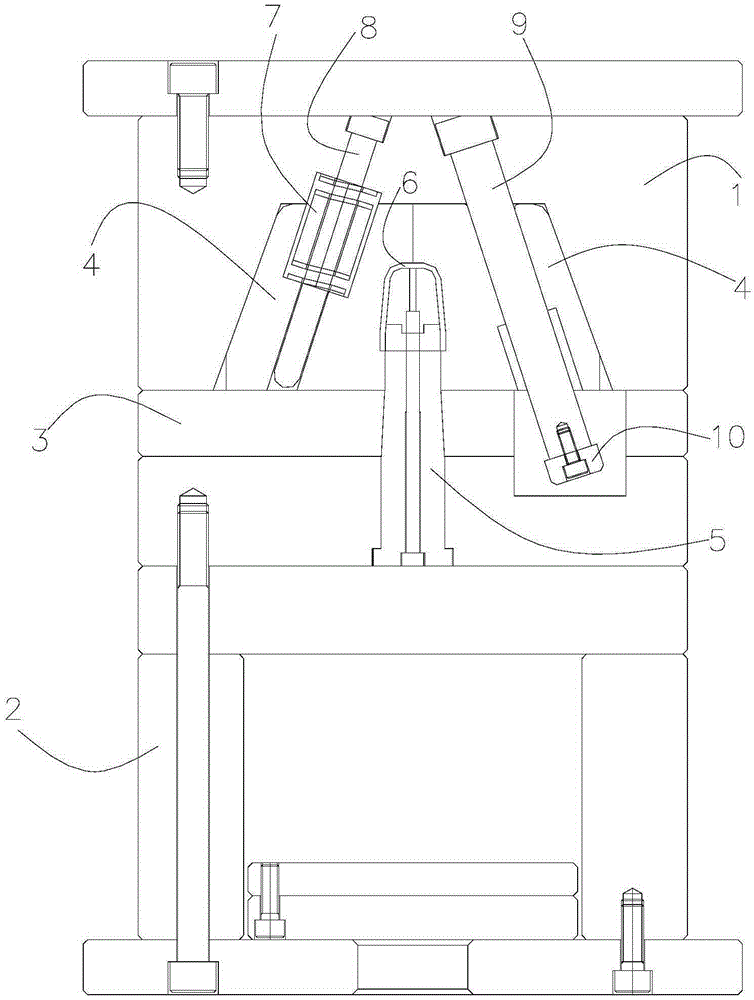

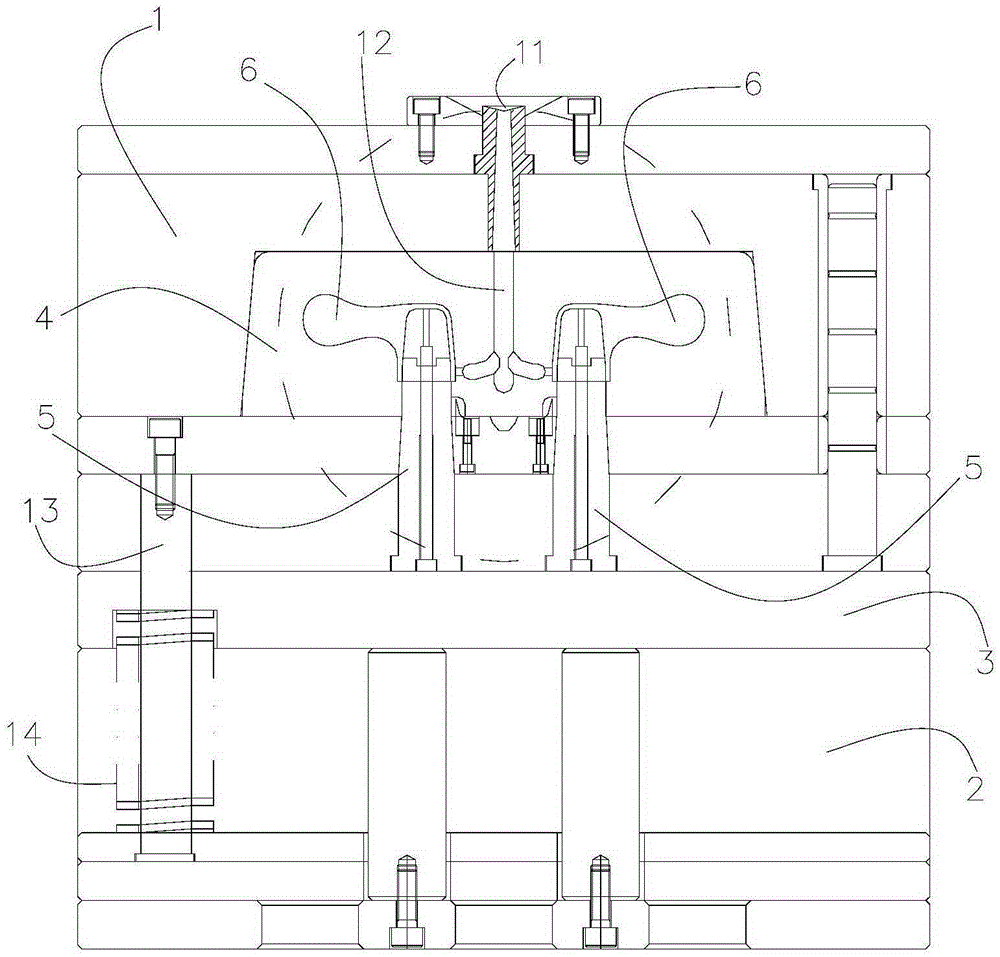

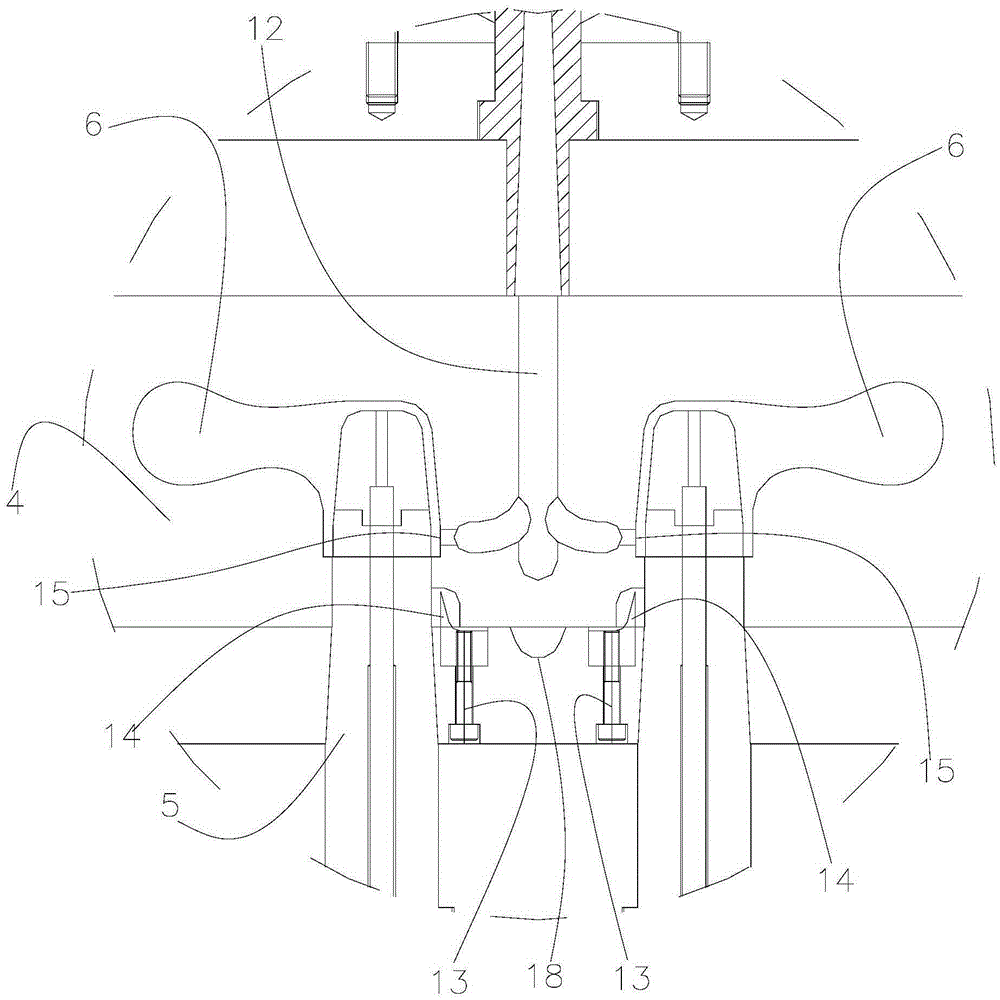

[0029] Such as Figure 1-6 As shown, an injection mold includes a front mold 1, a rear mold 2, a push plate 3 located between the front mold 1 and the rear mold 2, and two pieces are embedded on the side of the front mold 1 facing the push plate 3. Slider 4, along the direction of the front and rear die 2, the slide block 4 is slidably connected with the front die 1 through an elastic device, and the rear die 2 is provided with a rear mold core 5 that passes through the push plate 3 and protrudes from the front die 1, and the front and rear dies 2. When the mold is closed, the elastic device is in a compressed state, and a mold cavity 6 is formed between the two slide blocks 4 and the rear mold core 5, and a nozzle 11 is opened on the outer surface of the front mold 1. There is a flow channel 12 connecting the nozzle 11 and the mold cavity 6, the flow channel 12 is provided with a flow channel opening 15 leading to the mold cavity 6, and a nozzle cutter is provided on the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com