Water drain device for top buffer layer of karst tunnel

A technology of drainage device and buffer layer, applied in drainage, safety device, mining equipment and other directions, can solve the problems of tunnel water seepage, hidden danger of tunnel safety, serious harm, etc., and achieve the effect of convenient installation and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

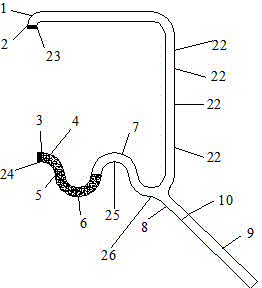

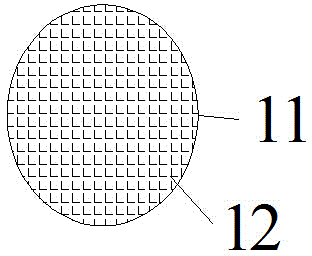

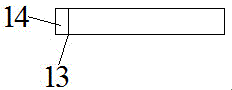

[0018] figure 1 Among them, a buffer layer drainage device at the top of a karst tunnel, which consists of an upper water inlet filter 2, a lower water inlet filter 3, an upper water inlet 1, a right-angle rod body 22, a lower water inlet 4, a connector 6, and activated carbon 5 , "S"-shaped connecting part 7, the main drain pipe 8 and the extended drain pipe 9. First, activated carbon is added into the connector 6 through the lower water inlet 4, and then the upper water inlet filter 2 and the lower water inlet filter 3 are connected to the upper water inlet 1 and the lower water inlet 4 respectively through screw connections, and then The extended drainage pipe 9 is connected with the main body drainage pipe 8 by thread to form the whole drainage device. The water in the buffer layer can be filtered from the lower water inlet 4 through the activated carbon 5 in the connector 6 to filter the fine sand in the buffer layer 15, and then through the "S"-shaped connection 7 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com