Tunnel supporting structure stress monitoring device and method

A force monitoring and supporting structure technology, applied in mining equipment, earthwork drilling, mining equipment, etc., can solve problems affecting the accuracy of calculation results, increasing deviation, and limited calculation and analysis level of monitoring results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

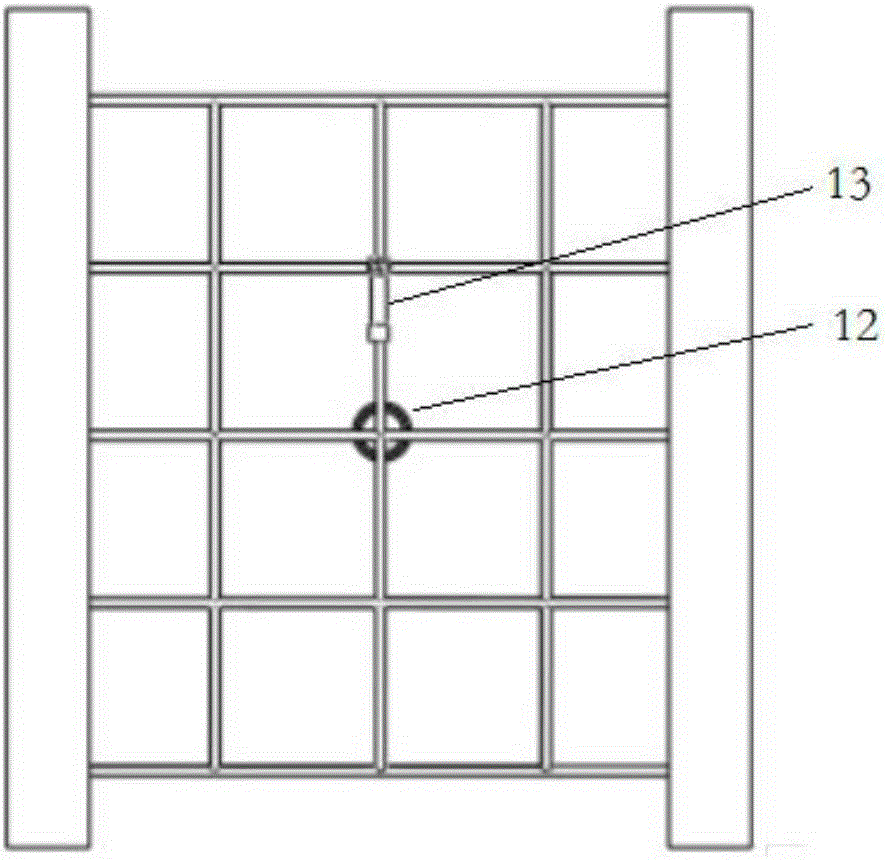

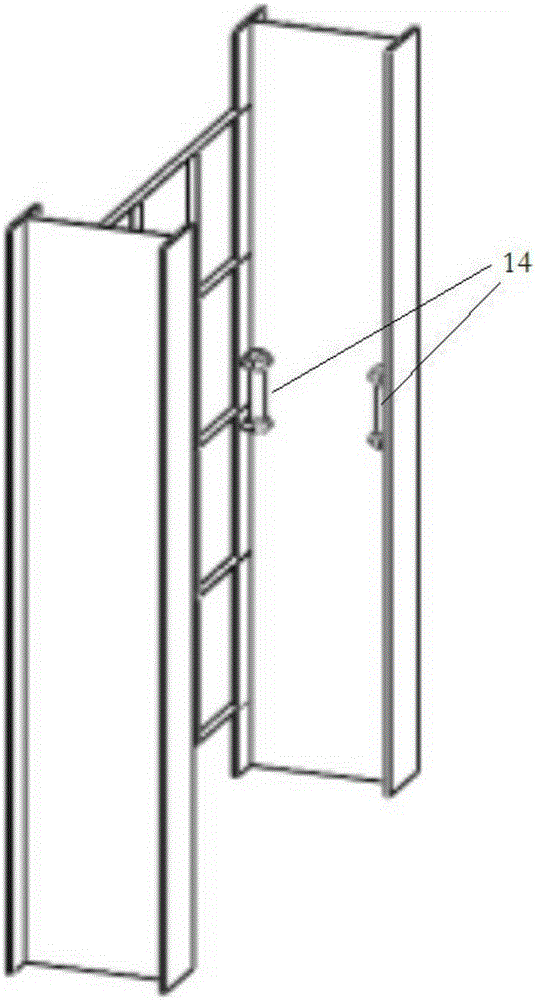

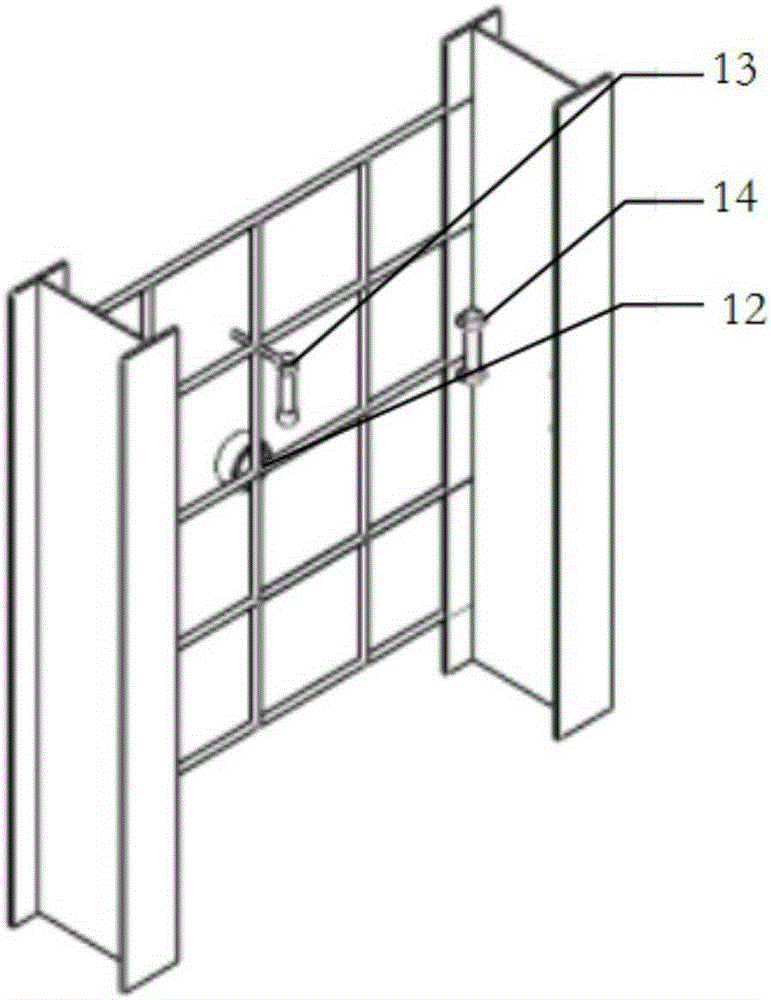

[0046] Such as Figure 1~5 As shown, a tunnel support structure force monitoring device includes a primary support force monitoring unit and a secondary lining force monitoring unit.

[0047] The primary support force monitoring unit includes a steel bar strain gauge 11 , a first earth pressure gauge 12 , a first concrete strain gauge 13 and a surface strain gauge 14 . Such as figure 2As shown, the section steel for the initial support is "I" type, and two surface strain gauges 14 are arranged on each section steel, and the two surface strain gauges 14 are symmetrically arranged inside the two wing plates of the section steel for monitoring the shape of the section steel wing plate. Tangential strain of the tunnel ring. There are three steel bar strain gauges 11, which are respectively arranged at 1 / 4, 1 / 2, and 3 / 4 of the anchor rods. The first earth pressure gauge 12 is arranged between the primary support and the surrounding rock, buried in the surrounding rock, and perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com