Shared oil smoke emission vertical pipe system and control method thereof

A technology of oil fume exhaust and oil fume exhaust fan, which is applied in the field of kitchen oil fume exhaust, and can solve problems such as waste of high-value space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

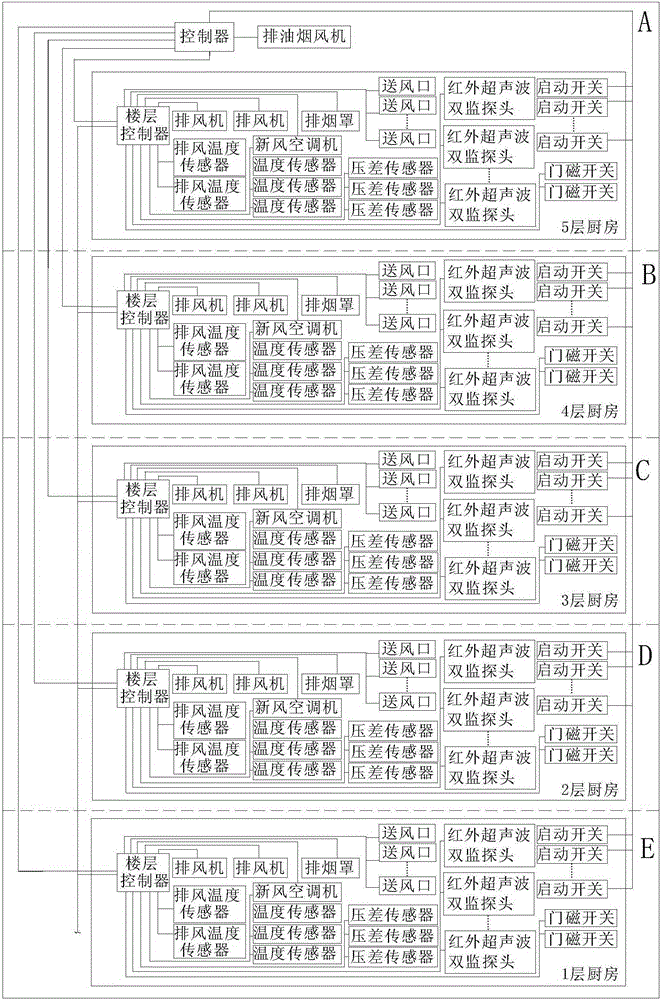

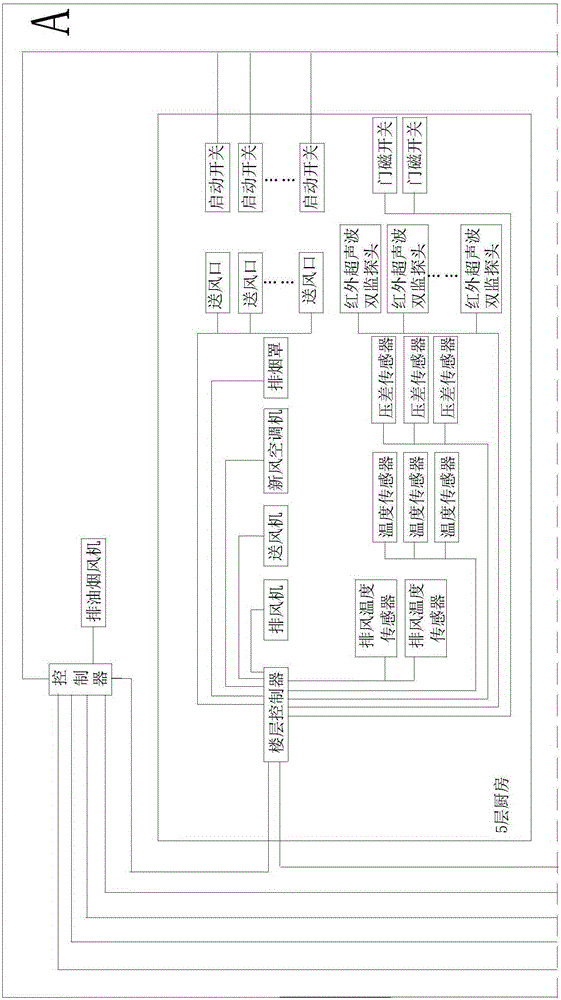

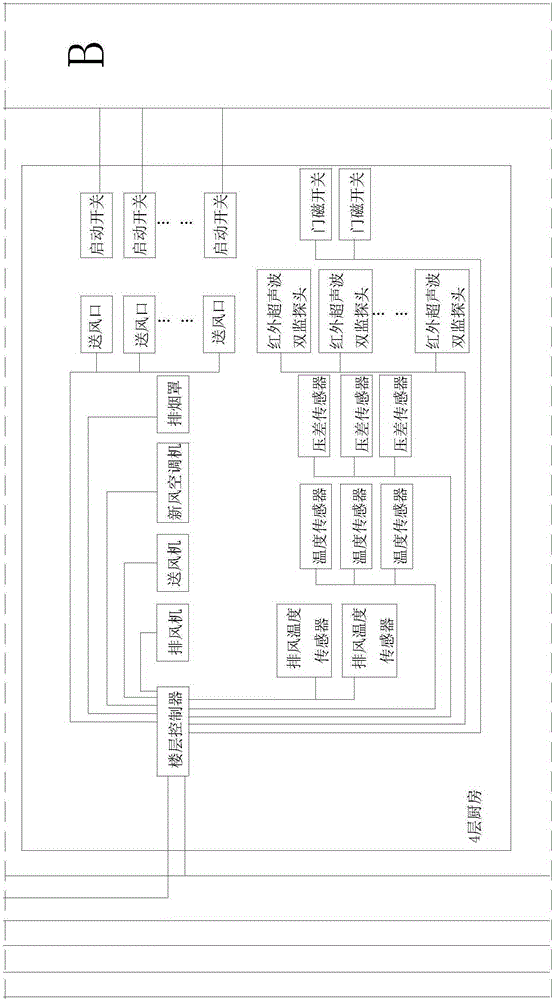

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0032] see figure 1 and figure 2 , the shared oil fume riser system provided by the embodiment of the present invention includes a controller, an oil fume blower, a frequency converter, an oil fume riser, and a plurality of oil fume horizontal pipe assemblies, and the oil fume horizontal pipe assembly includes a valve assembly and an oil fume exhaust pipe assembly. Horizontal Pipe. The oil fume exhaust horizontal pipe in each kitchen includes one or more sections. Among them, in figure 2 In , the oil fume exhaust standpipe is located on the right side of the figure, represented by the thick vertical line connected to the quantitative air valve and the electric valve on the right side of the figure.

[0033] The shared oil fume exhaust riser system of this embodiment can be applied to hotels and large commercial complexes with multiple kitchens. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com