Tread pattern rigidity and friction characteristic testing platform

A technology of friction characteristics and tire pattern, which is applied in the field of tire performance testing devices, can solve problems such as large data errors, large performance gaps, and inability to truly reflect the performance of finished tires, and achieve long service life, uniform force, and high data accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

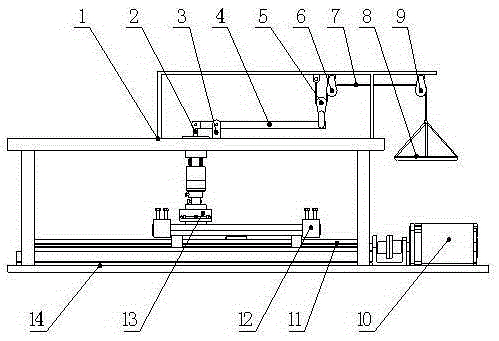

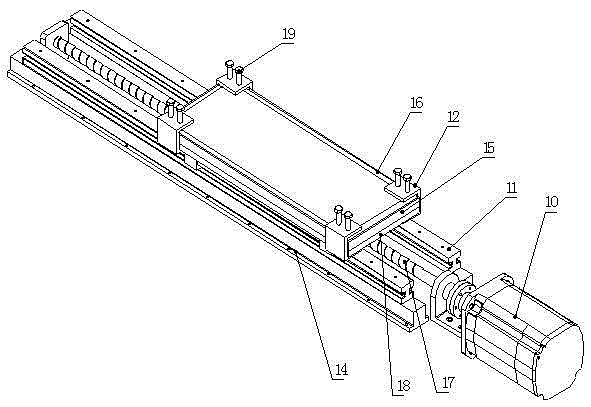

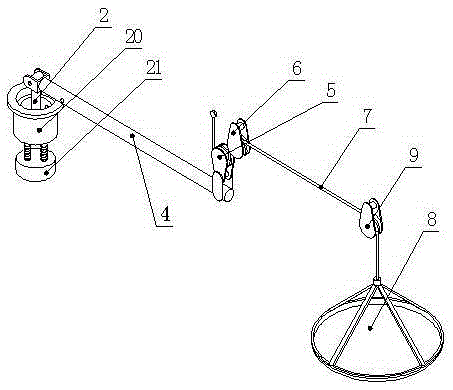

[0017] Such as Figure 1-4 A tire pattern stiffness and friction characteristic testing device shown includes a base 14, a support frame 1, a simulated road driving device, a sample fixture, a pressure detection device and a pressurizing device, and the supporting frame 1 and the simulated road driving device are located on On the base 14, the simulated road driving device is used to clamp the simulated road and drive its horizontal movement; figure 1 , figure 2 It can be seen from the figure that the simulated road surface driving device includes a linear guide rail 11, a simulated road surface holder and a drive motor 10, the simulated road surface holder is matched with the linear guide rail 11 and is installed on the linear guide rail, and the drive motor 10 is slidable along the linear guide rail. It is arranged at one end of the linear guide rail 11, and the simulated road clamp is connected with the driving motor through a ball screw. The nut of the ball screw is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com