Preparation method of fracturing physical model sample of coal-bearing production layer group

A technology of coal production layer and physical model, which is applied in the preparation of test samples, etc., can solve the problems of inability to effectively simulate the properties of natural fractures and the inability to accurately simulate the difference in physical properties between layered samples, and achieve a reduction in borehole wall The risk of instability, the prevention of coal rock being crushed, and the effect of ensuring uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

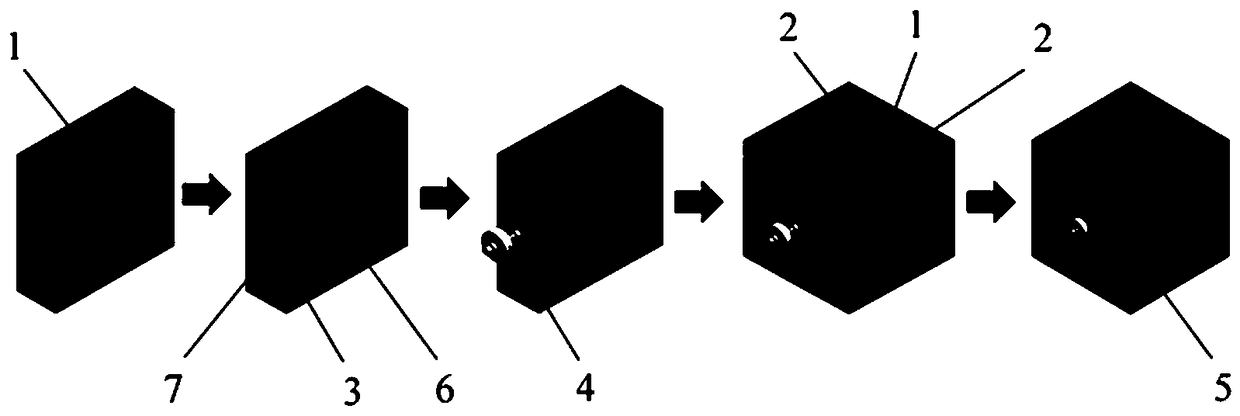

[0037] Such as figure 1 As shown, according to an embodiment of the preparation method of the coal-bearing formation group fracturing model sample of the present invention, it comprises the following steps in order:

[0038] Step 1: Analyze the characteristics of the coal-bearing formations to be simulated, select the coal and rocks for the preparation of phantom samples, and according to the lithological characteristics of each rock sample in the actual coal-bearing formations, extract the outcropped coal and rocks Processed into cuboid thin plates of the same size;

[0039] Step 2: Drilling a simulated wellbore 3 on the rock sheet 1, and cementing the simulated wellbore 4 in the simulated wellbore 3;

[0040] Step 3: taking the rock sheet 1 cemented with the simulated shaft 4 as the middle layer, and respectively cementing the coal and rock sheets 2 on both sides of the rock sheet 1 to form a coal-bearing production layer combination;

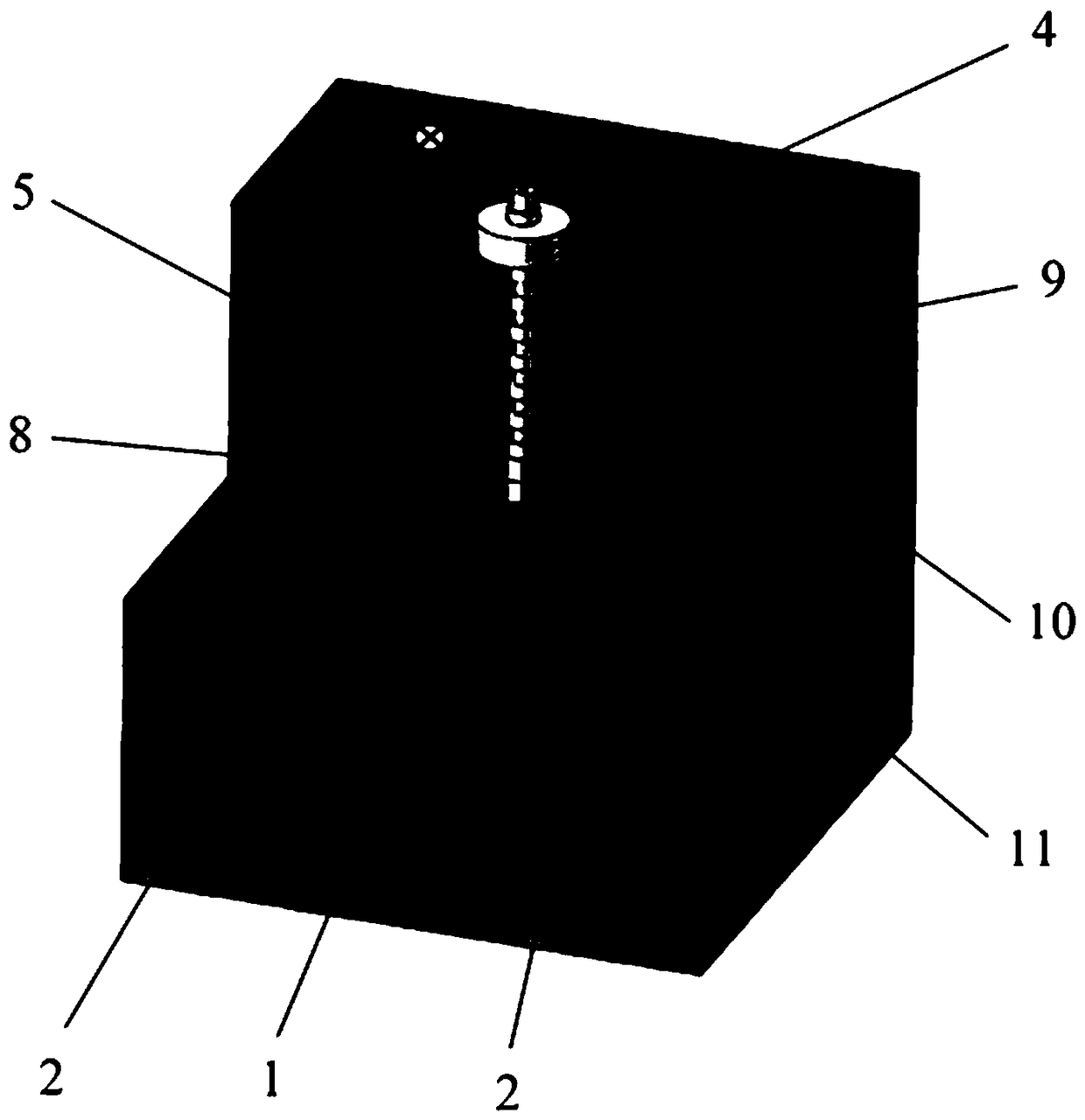

[0041] Step 4: Select the wrapping l...

Embodiment 2

[0051] According to another embodiment of the preparation method of the coal-bearing formation group fracturing model sample of the present invention, its preparation steps, principle and beneficial effect etc. are all the same as Embodiment 1, the difference is:

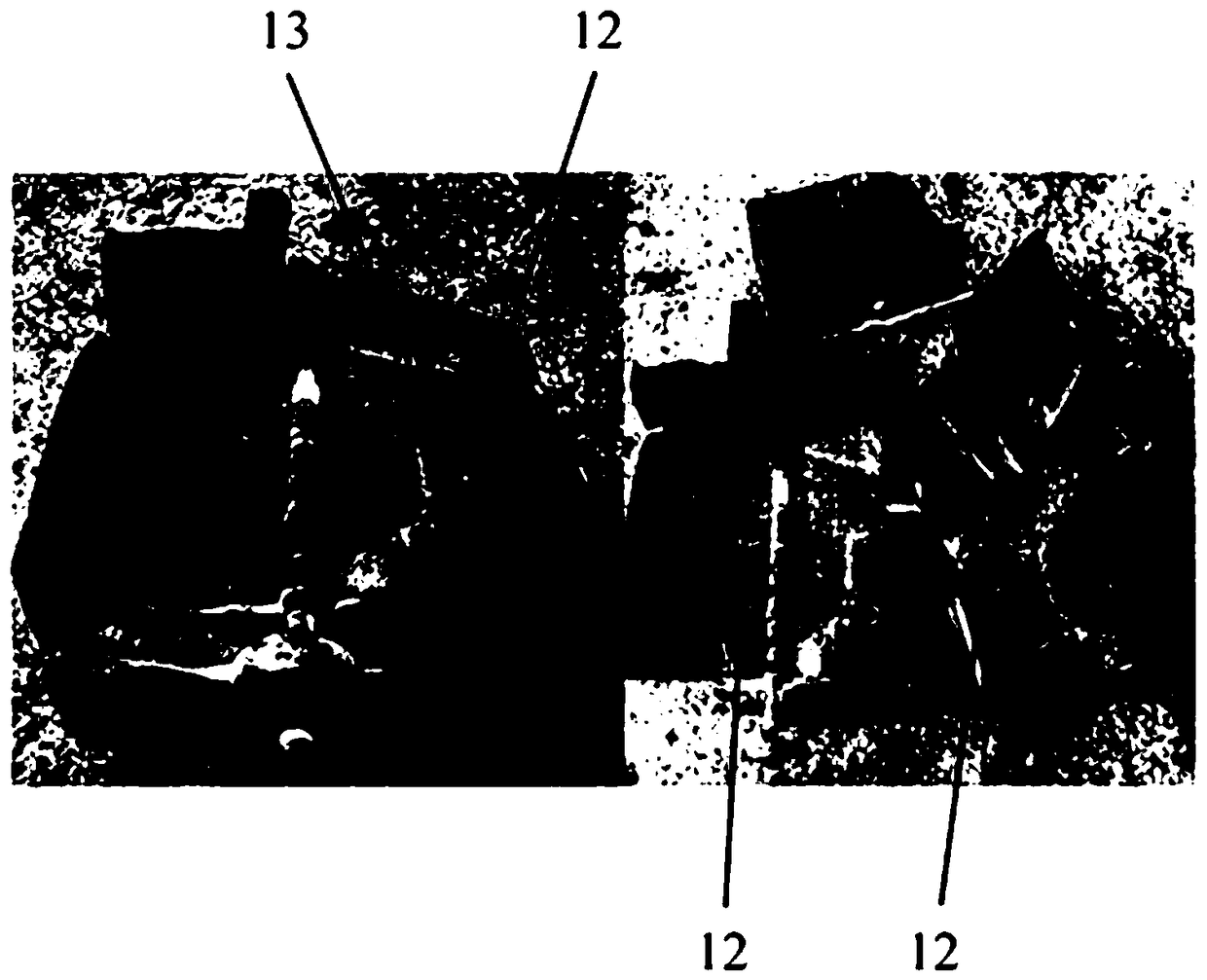

[0052] Natural coal outcrops and natural sandstone outcrops in the Linxing area on the eastern margin of the Ordos Basin, China were selected to prepare coal-sandstone-coal composite fracturing phantom samples. The diameter of the simulated wellbore is 20mm and the length is 170mm; the inner diameter of the simulated wellbore is 6mm, the outer diameter is 16mm, and the length is 190mm; the open hole section reserved at the lower end of the simulated wellbore is 40mm, and the simulated wellbore The uncemented simulated wellbore reserved at the upper end of the eye is 60mm. The simulated wellbore was cemented in the simulated wellbore with AB silica gel, and the cementing time was 9 hours. Use AB silica gel to glue t...

Embodiment 3

[0054] According to another embodiment of the preparation method of the coal-bearing formation group fracturing model sample of the present invention, its preparation steps, principle and beneficial effect etc. are all the same as Embodiment 1, the difference is:

[0055] The natural coal outcrops and natural limestone outcrops in the Linxing area on the eastern margin of the Ordos Basin, China were selected to prepare coal rock-limestone-coal rock composite fracturing phantom samples. The diameter of the simulated wellbore is 20mm, and the length is 180mm; the inner diameter of the simulated wellbore is 6mm, the outer diameter is 16mm, and the length is 200mm; The uncemented simulated wellbore reserved at the upper end of the eye is 70mm. The simulated wellbore was cemented in the simulated wellbore with AB silica gel, and the cementing time was 10 hours. Use AB silica gel to glue the coal rock sheet to the wide surfaces on both sides of the rock sheet, and the bonding time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com