Water-based anticorrosive paint

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of long film-forming time, difficulty in uniform dispersion, and difficulty in exerting anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

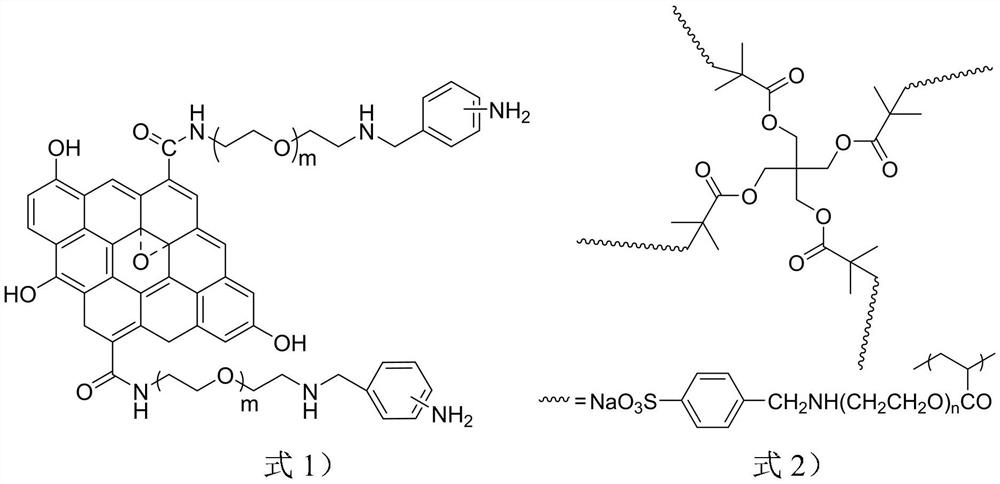

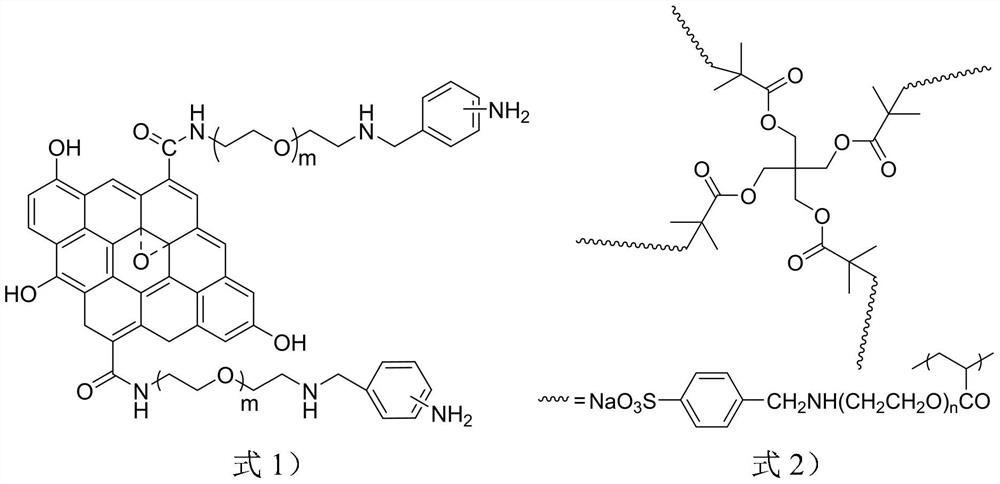

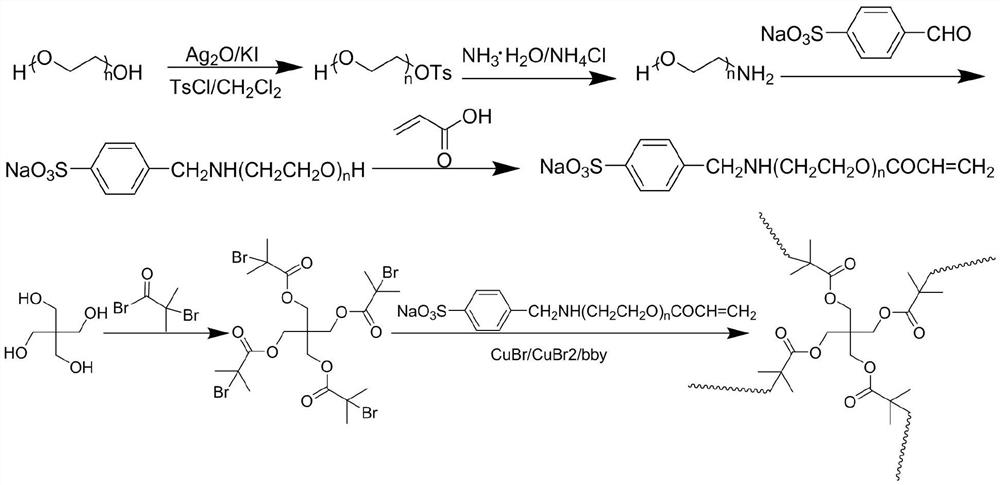

[0028] Wherein the preparation method of auxiliary dispersant comprises the following steps:

[0029] S1: Add polyethylene glycol (PEG-600) and dichloromethane into the reaction bottle and stir to mix evenly, add a catalytic amount of silver oxide / potassium iodide catalyst, and then add p-toluenesulfonate in an equimolar amount to polyethylene glycol Acyl chloride, stirred and reacted at room temperature for 2-3 hours, then filtered and washed to obtain TsO-PEG-OH;

[0030] S2: Dissolve TsO-PEG-OH in 25% ammonia water, add an equimolar amount of ammonium chloride, stir and react at 30°C for 3 days, extract with dichloromethane, and separate the collected organic layer by column chromatography Purify to NH 2 -PEG-OH;

[0031] S3: NH to be obtained 2 -Dissolve PEG-OH in deionized water, add an equimolar amount of benzaldehyde-4-sodium sulfonate, adjust the pH to 6.5 to obtain a mixed solution, take sodium aminoborohydride drop by drop into the mixed solution, and stir for 12 ...

Embodiment 1

[0045] Preparation of multifunctional auxiliary agent: according to the above preparation process, wherein the molecular weight of polyethylene glycol diamine is 400g / mol, and modified graphene is obtained; 15g of modified graphene and 10g of auxiliary dispersant are dispersed in 100g of water to obtain a Multifunctional additives containing graphene nanomaterials.

[0046] Weigh 40g water-based polyurethane emulsion, 15g pigments and fillers (10g talcum powder, 5g aluminum tripolyphosphate), 5g multifunctional additives, 0.2g carboxymethylcellulose thickener, 1g diethylenetriamine curing agent and 5g water to mix uniform.

Embodiment 2

[0048] Preparation of multifunctional auxiliary agent: according to the above preparation process, wherein the molecular weight of polyethylene glycol diamine is 1000g / mol, and modified graphene is obtained; 10g of modified graphene and 8g of auxiliary dispersant are dispersed in 100g of water to obtain a Multifunctional additives containing graphene nanomaterials.

[0049] Weigh 20g of water-based styrene-acrylic emulsion, 30g of water-based epoxy emulsion, 15g of pigments and fillers (15g of titanium dioxide), 8g of multifunctional additives, 0.2g of methyl cellulose thickener, 6g of diethylenetriamine curing agent and 5g of water to mix uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com