Detection device used for direct measuring of engine tail gas particulate matter number concentration

A detection device and tail gas particle technology, which is applied in the direction of measurement device, particle suspension analysis, suspension and porous material analysis, etc., to achieve the effect of facilitating flow parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

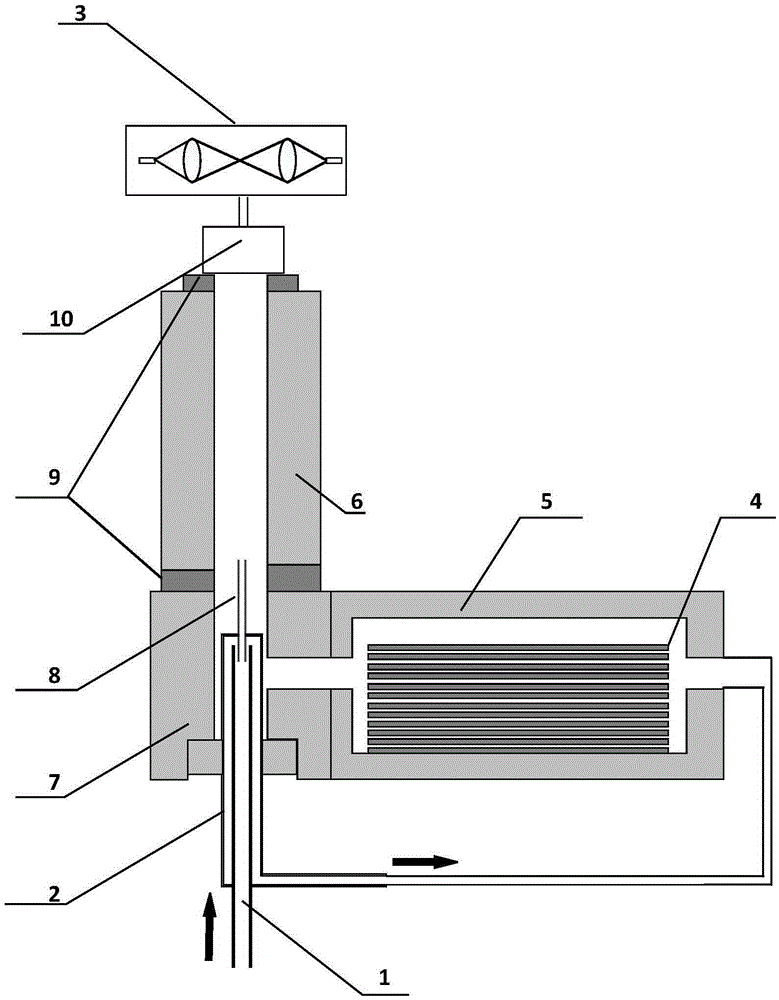

[0023] The detection device for measuring the number concentration of engine exhaust particulate matter, its structure schematic diagram is as follows figure 1 As shown, it includes an intake pipe 1, a capillary tube 8, a connecting pipe 2, a saturator 5, a condenser 6, an intermediate connecting piece 7, a mixing chamber 10, an optical particle counter 3 and a diesel particulate filter 4, wherein one end of the connecting pipe 2 Connect the intermediate connecting piece 7, one end of the connecting pipe 7 is inserted into the intermediate connecting piece 7, but not communicated with the connecting piece, at this end, the air inlet pipe 1 is inserted into the connecting pipe 2, and one end of the air inlet pipe 1 is provided with a capillary 8, The capillary 8 passes through the connecting pipe, and the length of the capillary 8 can reach the condenser, that is, the capillary 8 communicates with the condenser 6, and the other end of the connecting pipe 2 communicates with the ...

Embodiment 2

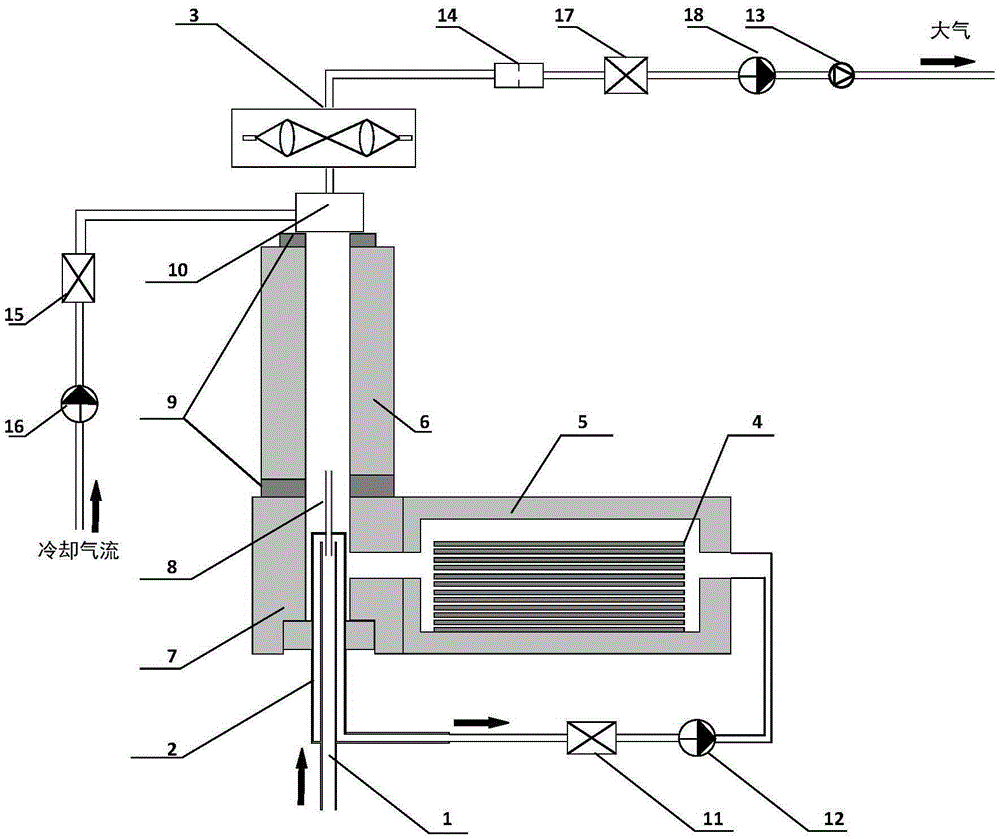

[0032] On the basis of Example 1, in order to make a part of the detected gas into clean air so that it serves as sheath gas, a first high-efficiency filter is set in the connecting pipe; in order to effectively control the airflow into the device for detection, in The connecting pipe is provided with a first rotameter. The first rotameter can be arranged on the connecting pipe connected to the saturator after the first high-efficiency filter.

[0033] In order to reduce the temperature of the gas outlet from the condenser, so as to ensure that the outlet airflow does not damage the photoelectric unit, an inlet is set at the other end of the mixing chamber, and the front end of the inlet is connected to a second high-efficiency filter to provide clean airflow for it at the same time. airflow. The second high-efficiency filter and the mixing chamber can be connected by pipelines; in order to effectively control the diluent gas flow rate to select suitable working conditions to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com