A detachable sample cage for a device for testing the expansion coefficient of explosives

A technology of volume expansion coefficient and testing equipment, which is applied in the direction of measuring equipment, fuel oil testing, and material inspection products. Avoid cumbersome test process, facilitate volume calibration, and simplify the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

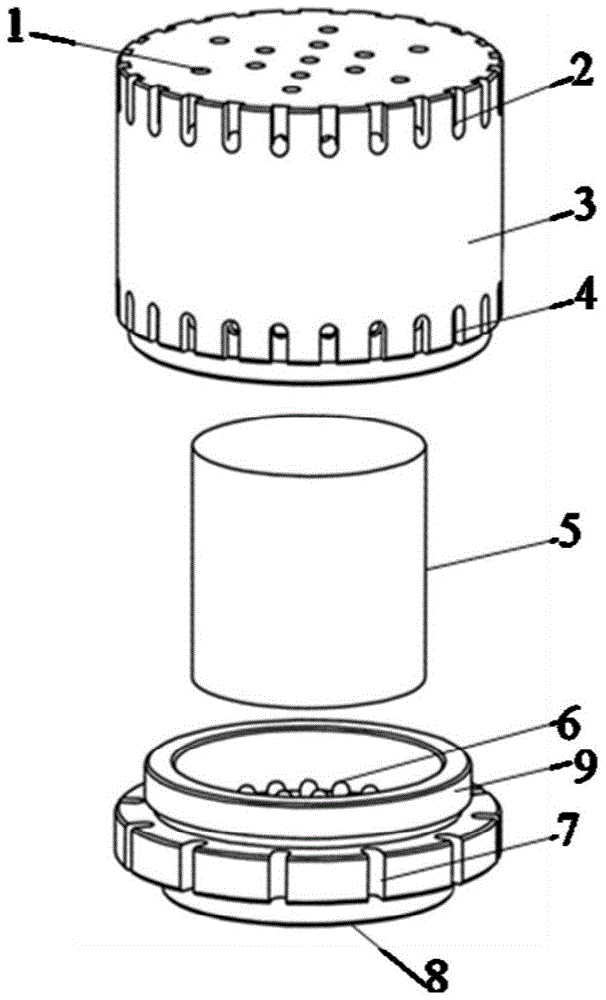

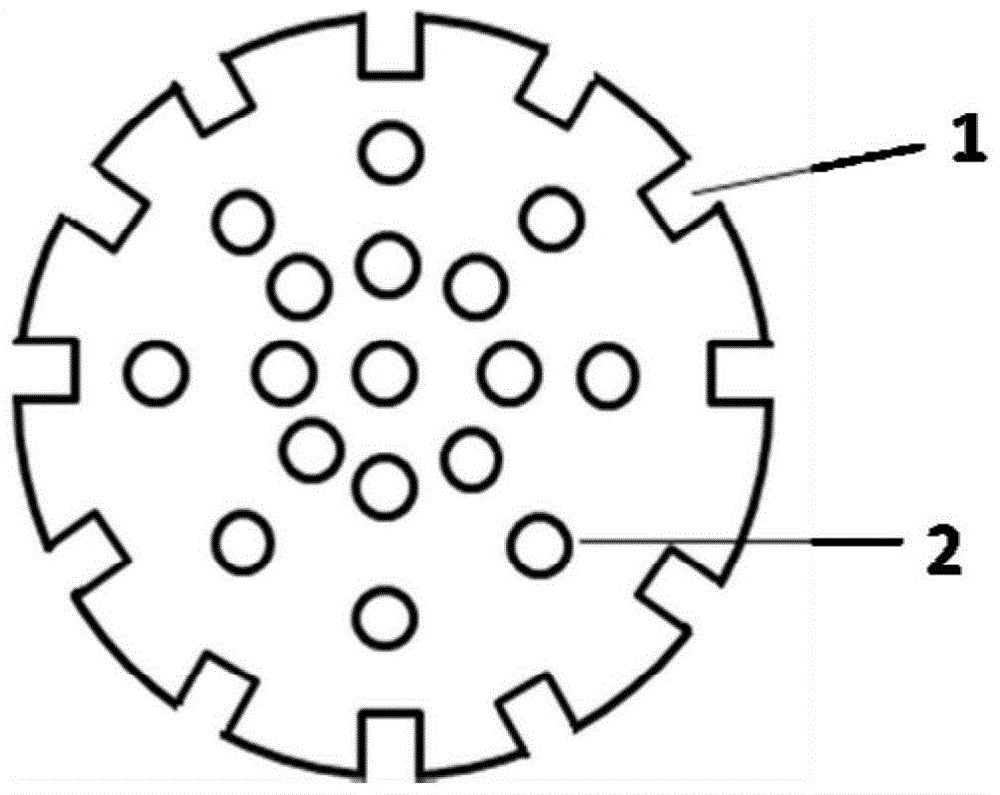

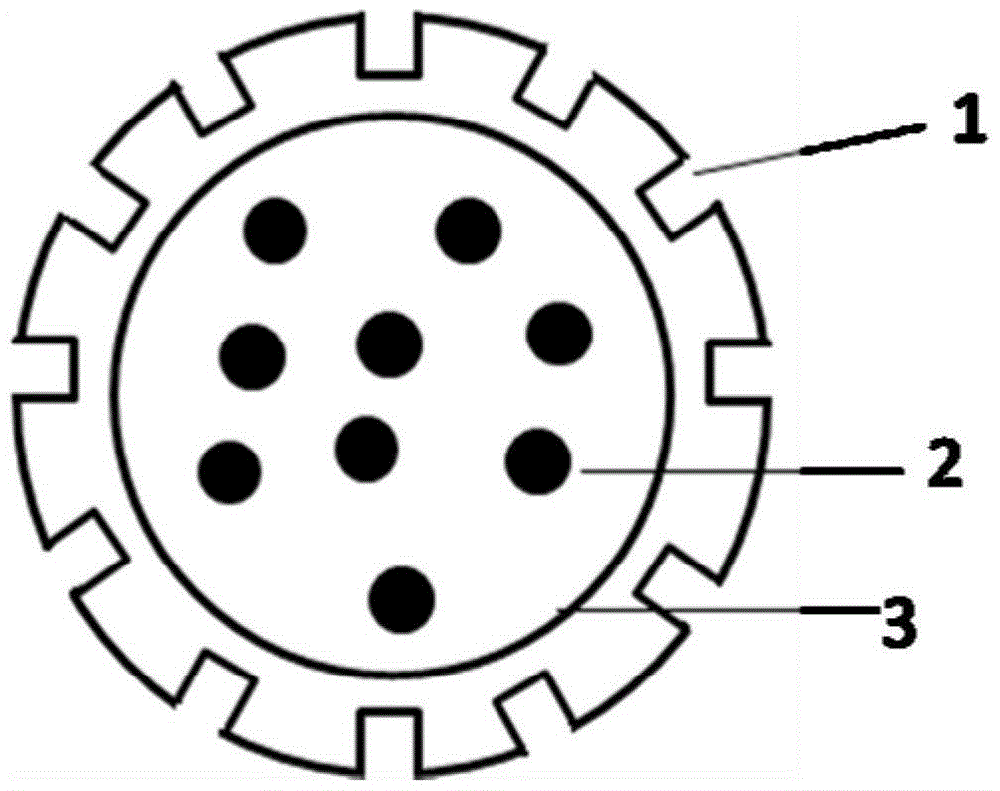

[0015] Such as figure 1 As shown, the experiment is carried out by using a propellant body expansion coefficient test device with an inner cavity size of φ41mm*H 41mm, and a detachable sample cage with a diameter of φ21mm*H 21mm and a wall thickness of 5mm is selected (wherein, φ is the inner diameter of the base, and H is the inner height ). During the test, first separate the cover plate 3 from the base 8, and place the sample 5 (the sample size is φ20mm*H 20mm) on the base to ensure that the surface of the sample does not contact the inner wall of the sample cage when the sample is fully expanded. Then place the cover plate 3 on the base, use the connection grooves 4 and 7 to fix the two together, then use the guide post cover plate connection groove 2 to fix the sample cage and the propellant body expansion coefficient testing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com