Arrangement device and arrangement method for pin electrodes in high-voltage electrostatic separator

A technology of high-voltage electrostatics and needle electrodes, which is applied to the separation of electrostatic effects, chemical instruments and methods, and solid separation, can solve the problems that the research methods of needle electrode arrangement cannot be implemented, and the position of needle electrodes cannot be adjusted freely. Low cost, good effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A needle electrode arrangement device for a high-voltage electrostatic separator.

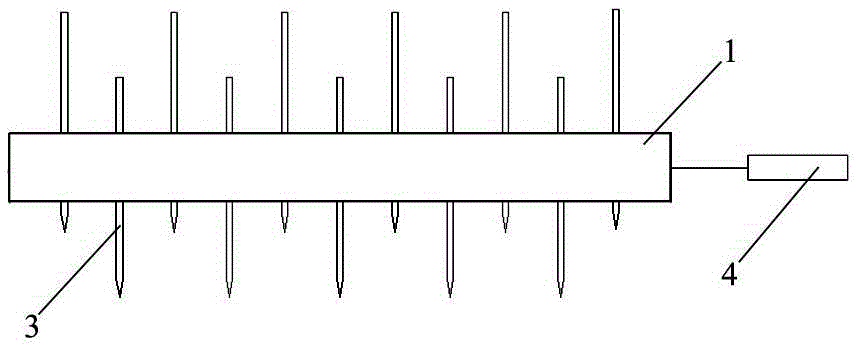

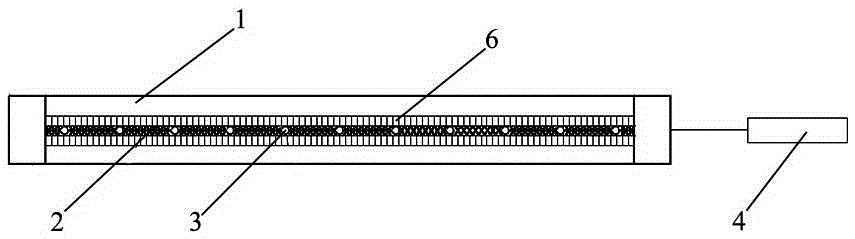

[0024] Such as Figure 1~Figure 3 As shown, the device of the present invention includes a circular tubular shell 1, a metal mesh filled column 2, a needle electrode 3 and a negative high-voltage power supply 4 and other parts.

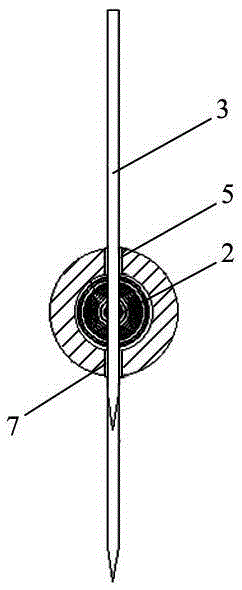

[0025] The shell 1 is an insulated hollow tubular structure made of polytetrafluoroethylene material with good high-voltage insulation performance. It is arranged inside the sorting machine and arranged parallel to its rotating roller to carry the needle electrode 3 . Two axial long holes are opened on the tube wall of the shell 1, which are respectively the first long hole 5 and the second long hole 7, and the first long hole 5 and the second long hole 7 are related to the shell 1. The central axis is symmetrical to form an insertion opening through which the needle electrodes 3 are arranged. The length of the long hole is slightly shorter than ...

Embodiment 2

[0027] Embodiment 2: A needle electrode arrangement method of a high-voltage electrostatic separator.

[0028] The inventive method comprises the following steps:

[0029] a. Set the needle electrode arrangement device of the high-voltage electrostatic separator described in Example 1.

[0030] b. Insert the needle electrodes 3 vertically from the long holes on the housing 1 so that they penetrate the metal mesh filled column 2, and make the tip of each needle electrode 3 point vertically to the roller shaft of the high-voltage electrostatic separator, and turn on the high-voltage power supply , all the needle electrodes 3 produce a discharge phenomenon for the roller, and the electric field intensity is measured and calculated.

[0031] c. Repeat step b according to the designed arrangement spacing of the needle electrodes and the distance between the tips of the needle electrodes and the surface of the roller.

[0032] d. According to the measured and calculated electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com