Oil paint rolling brush shell

A paint roller and paint technology, applied in coating, packaging, and devices for coating liquid on the surface, can solve the problems of paint drying and unfavorable blister sealing, etc., and achieve the effect of increasing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

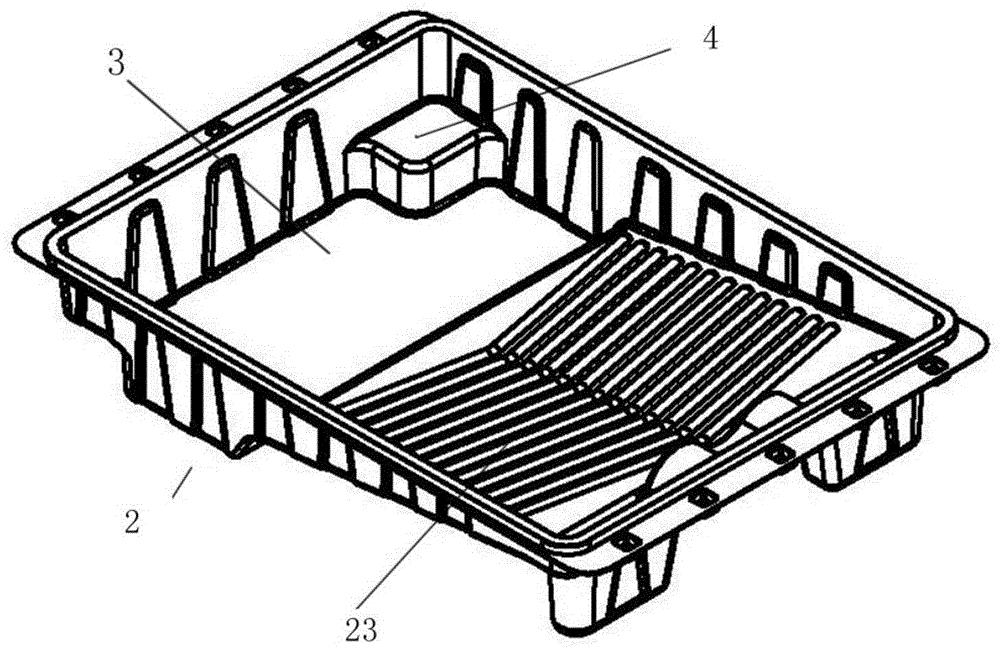

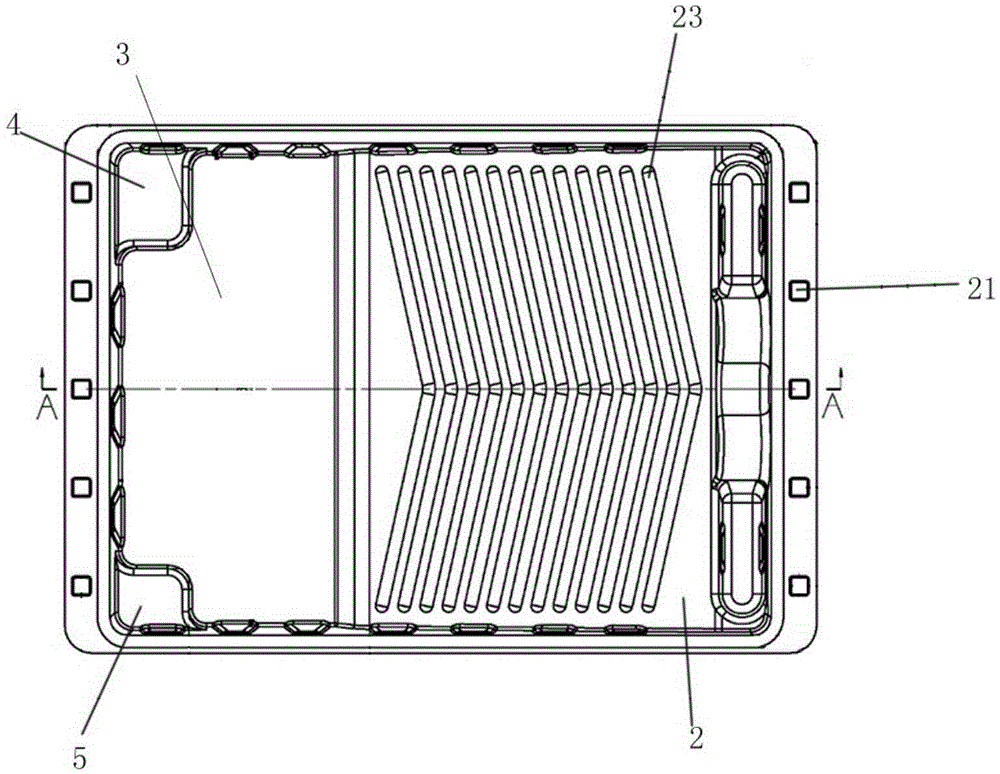

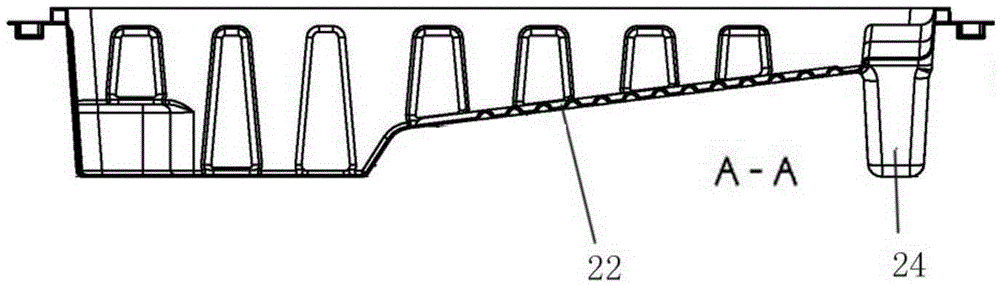

[0021] The present invention comprises bulb 2, and described bulb 2 is provided with paint storage pit, and in described paint storage pit is paint storage space 3, and described storage space 3 stores the redundant paint from roller brush, and described roller brush is not in use , rest on two protrusions, which are respectively formed on both sides of the bulb 2, and which are higher than the paint storage space 3 in the paint storage pit.

[0022] The two protrusions are the right protrusion 4 and the left protrusion 5, and the right protrusion 4 and the left protrusion 5 jointly form a part of the shelf supporting the roller brush, that is, the right protrusion 4 and the left protrusion 5 are the left and right sides of the shelf respectively. The two ends, the two ends of the rolling brush can rest on the right protrusion 4 and the left protrusion 5 respectively, and the middle is suspended. There is a larger space between the right protrusion 4 and the left protrusion 5,...

Embodiment 2

[0039] Present embodiment 2 is similar to embodiment 1, also comprises bulb shell 2, is provided with paint storage pit in described bulb shell 2, is paint storage space 3 in the described paint storage pit, and described storage space 3 stores the excess oil from the roller brush. The paint, when the roller brush is not in use, rests on two protrusions, the protrusions are respectively formed on both sides of the bulb shell 2, and the protrusions are higher than the paint storage space 3 in the paint storage pit.

[0040] The two protrusions are the right protrusion 4 and the left protrusion 5. The difference from embodiment 1 is that the right protrusion 4 and the left protrusion 5 are provided with pits for supporting the roller brush. There is a larger space between the right protrusion 4 and the left protrusion 5, so that the roller brush can release excess paint, that is, the paint is released in the paint storage space 3 below.

[0041]The difference between this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com