Anti-clogging trommel screen with secondary screening device

A technology of drum sieve and secondary sieve, which is applied in the direction of filtration, solid separation, and separation of solids from solids with airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

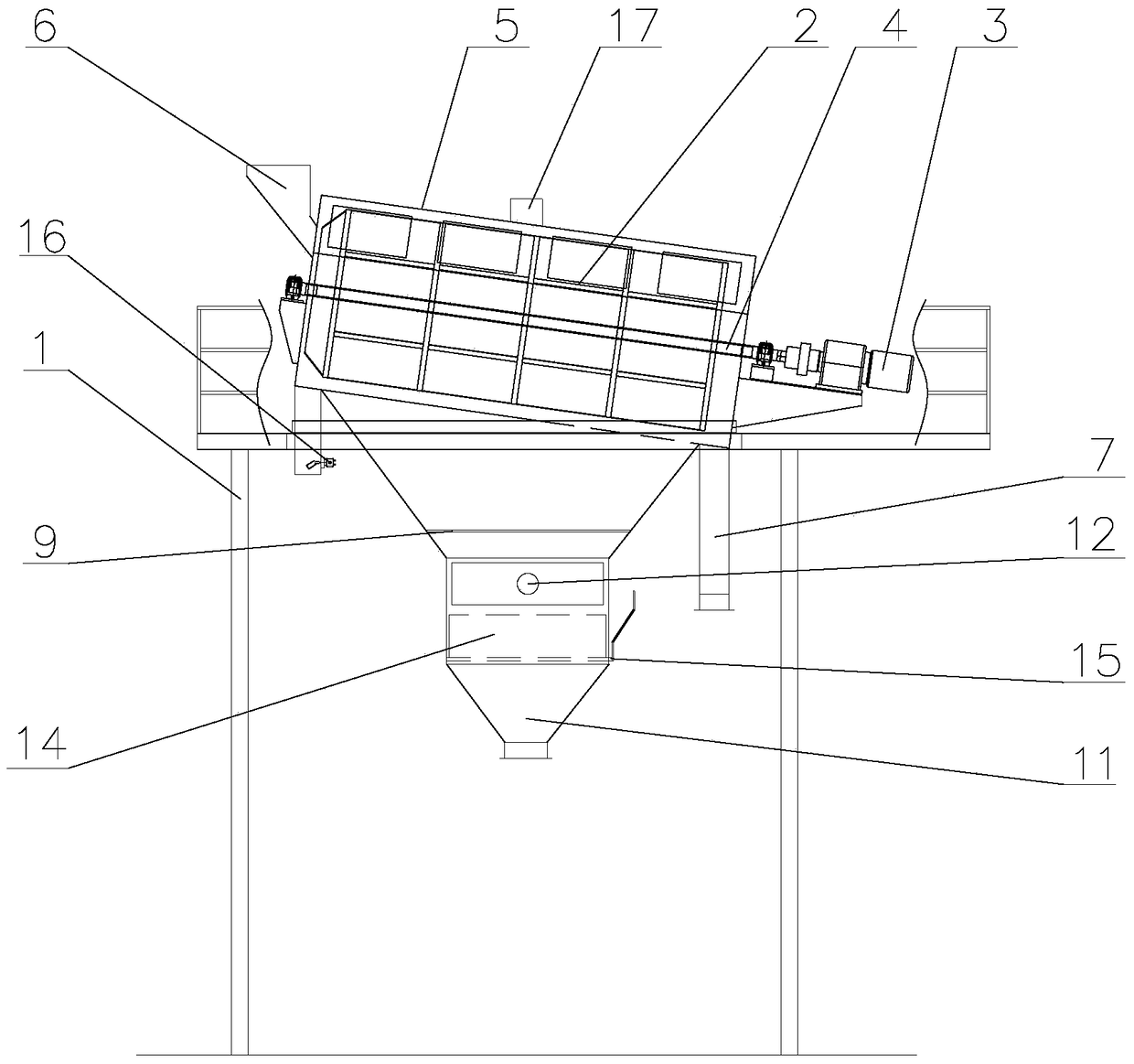

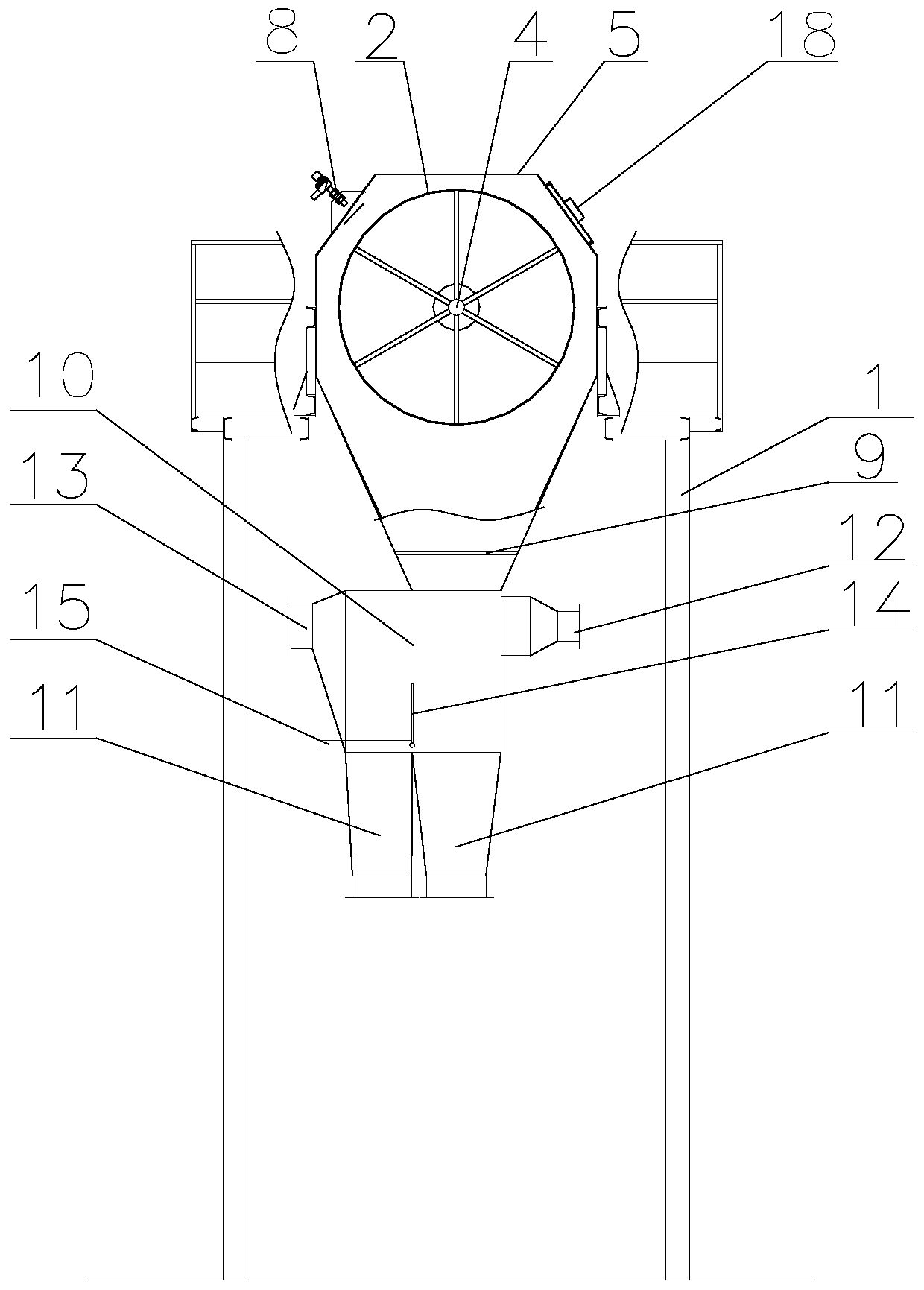

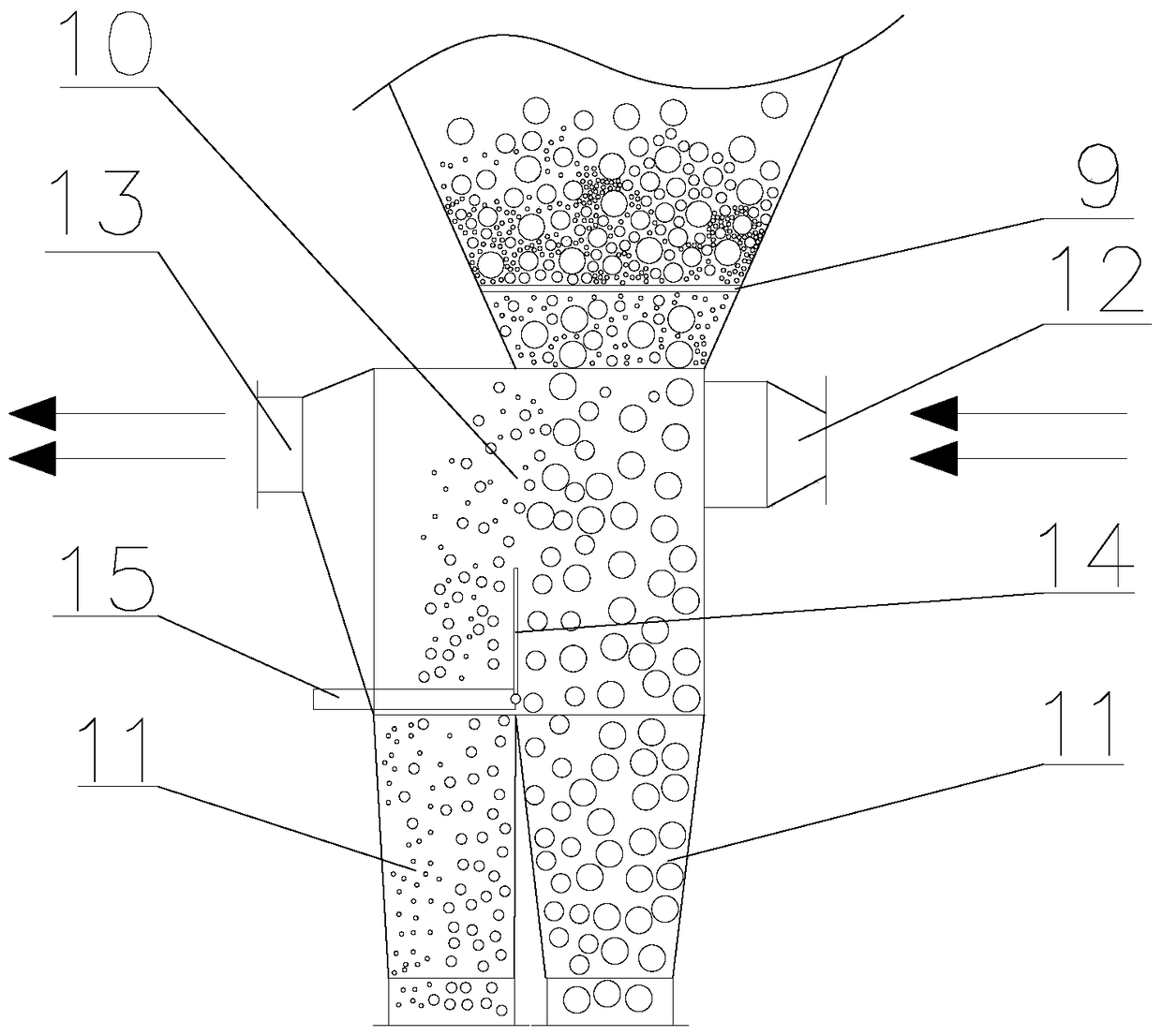

[0020] like Figure 1~3 The shown anti-blocking trommel screen with a secondary screening device is mainly composed of a frame 1, a trommel screen 2, a rotating motor 3, a rotating shaft 4, an outer cover 5, a feed inlet 6 arranged at one end of the outer cover 5, and a The waste material outlet 7 at the other end of the outer cover 5, the anti-blocking device 8 and the secondary screening device located at the lower end of the outer cover 5; the trommel 2 is arranged on the frame 1 at 5° to 10° with the horizontal plane; such a design can It is convenient for the clogged material blown off by the air cannon to be discharged from the waste material outlet 7. A rotating shaft 4 is inserted inside the trommel 2, and one end of the rotating shaft 4 passes through the trommel 2 to connect to the rotating motor 3, and the outer cover 5 is surrounded and arranged on the outside of the trommel 2, and a plurality of anti-corrosion The blocking device 8; the anti-blocking device 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com