Touch screen piece washing table

A technology of touch screen and film washing, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. It can solve the problems of waste of water resources, production efficiency, ground environmental pollution, and low work efficiency, so as to achieve no waste Water resources, good cleaning effect, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

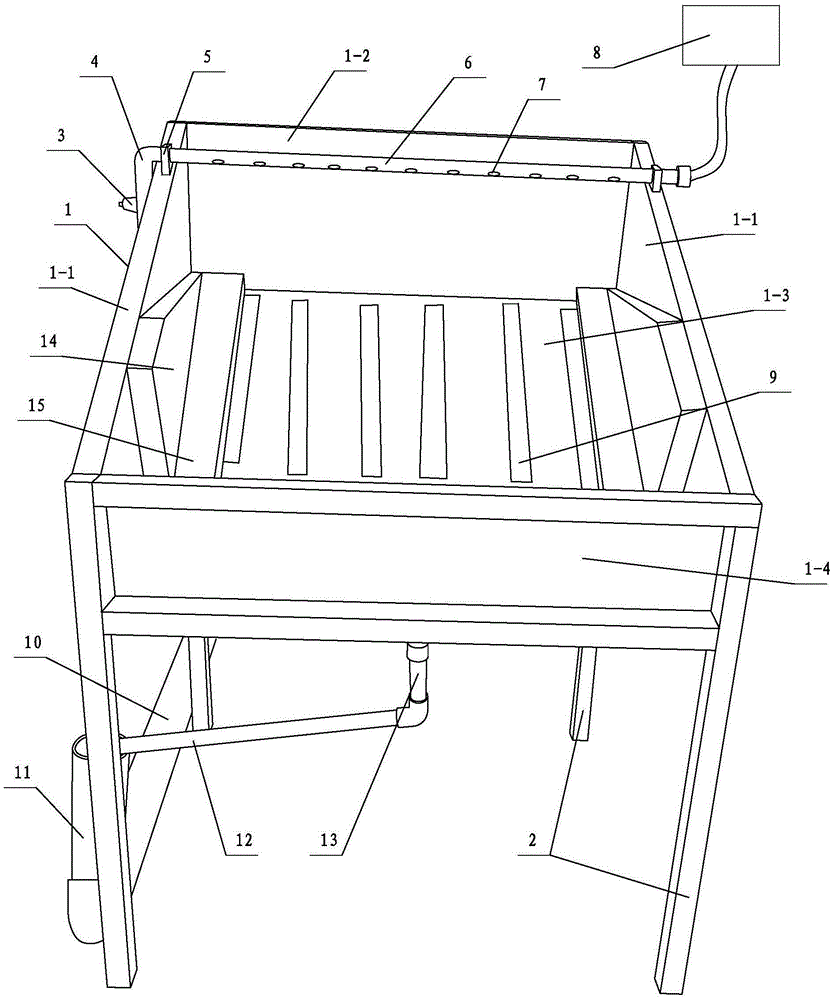

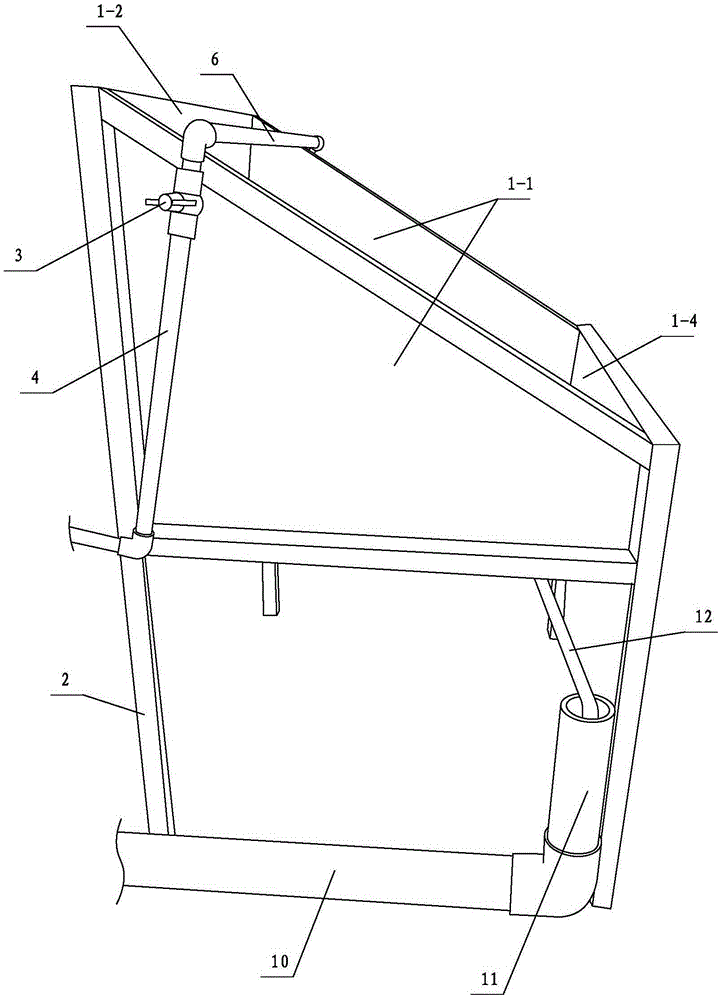

[0027] by figure 1 with figure 2 As shown in the schematic diagram of the structure of the touch screen raw film processing table of the present invention, it can be seen that it includes a storage box for placing the touch screen sheet, a spray device and a draining device, and a positioning device for positioning the touch screen sheet is provided in the storage box. The spray device is located above the accommodating box and communicates with an external water source, and the drainage device is located at the bottom of the accommodating box and communicates with the accommodating box.

[0028] The accommodating box includes a box body 1 and legs 2, and four legs 2 are fixedly connected to the four corners of the bottom of the box body 1 respectively. The box body 1 includes a front plate 1-4, a back plate 1-2, a bottom plate 1-3, and two side plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap