Roller nosing machine

A technology of closing machine and roller, which is applied in the direction of feeding device, positioning device, storage device, etc., which can solve the problems of unguaranteed accuracy, difficult processing, and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

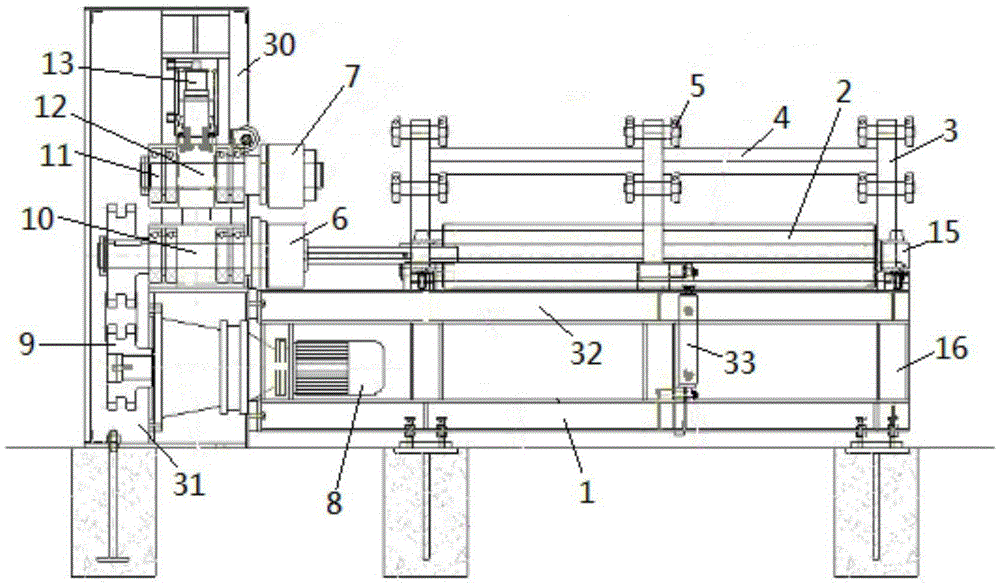

[0028] See figure 2 and Figure 4 , a roller closing machine, including a frame 1, a roller support part fixed on the frame 1, a pressure applying mechanism and a driving part, the roller support part includes a pressure receiving mechanism, a movable end table 15 and an end table fixed at one end of the frame A slide bar is provided at the bottom of the movable end table 15, and the end table mobile seat is provided with a chute for the slide bar to pass through.

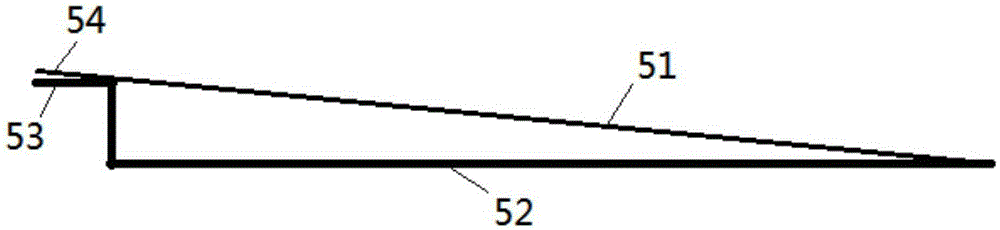

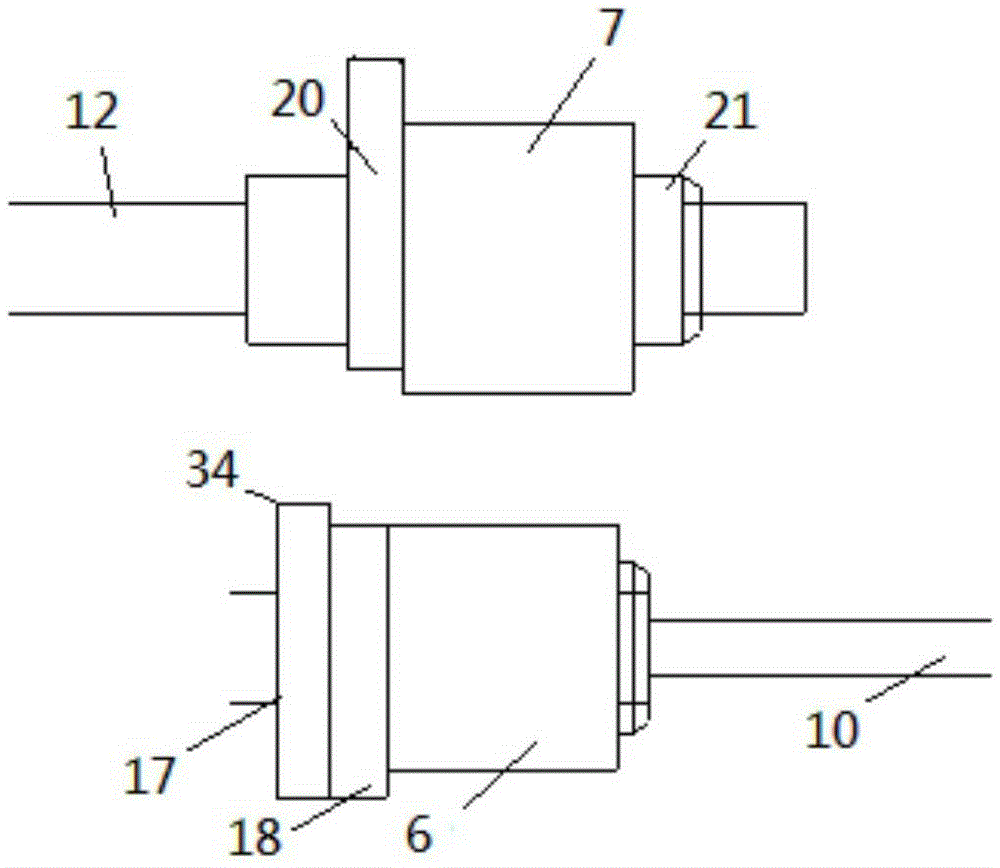

[0029] The first molding roller includes a first molding roller body 10 and a first molding roller 6 sleeved on the first molding roller body 10 . The pressurized mechanism includes a die roller shaft seat 30 fixed at one end of the frame 1, a first die roller body 10, a first die roller 6 and a fixed ring, and the die roller shaft seat 30 is set There is a shaft hole through which the first molding roller body 10 passes, and the fixed ring includes a first spinning ring 18 and a retaining ring 17, and the retai...

Embodiment 2

[0037] Embodiment 2 is basically the same as the roller closing machine described in Embodiment 1, the difference is:

[0038] The first spinning ring 18 includes a fixed inner ring and a rolling outer ring rolling on the fixed inner ring, the retaining ring 17 includes a resisting protrusion 34 protruding from the edge of the rolling outer ring, and the second die roller body 12 A second spinning ring 20 corresponding to the rolling outer ring is sleeved, and those skilled in the art can replace the width of the second spinning ring 20 according to different thicknesses of the rollers.

Embodiment 3

[0040] Embodiment 3 is basically the same as the drum closing machine described in Embodiment 1, the difference is:

[0041] The roller supporting part does not include an end table moving seat and a movable end table. The first die roller shaft seat 30 is provided with an elongated shaft hole for the first die roller body 10 to slide, and the pressure receiving end of the pressure cylinder is provided with a There is a shaft hole for the first molding roller body 10 to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com