Pin bending fixture for CQFJ product

A product and pin technology, which is applied in the field of pin bending fixtures, can solve the problems of left and right asymmetry of finished products, unsightly work efficiency, etc., and achieve the effect of reducing requirements, improving work efficiency, and facilitating pin bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

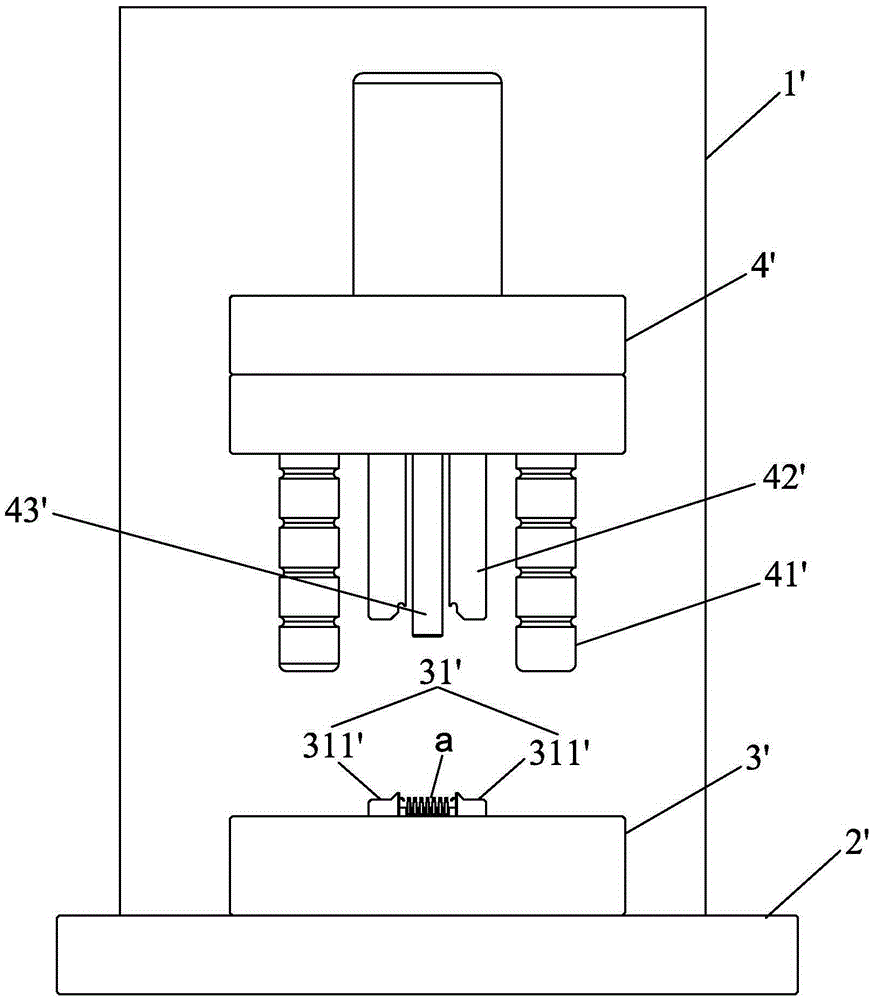

[0009] Such as figure 1 As shown, the pin bending fixture used for CQFJ products of the present invention includes a frame 1 ', a horizontal workbench 2' installed on the frame 1', a lower mold 3' placed on the workbench, and a lower mold 3' above the upper mold 4' that slides up and down along the frame 1' and the transmission device (not shown) that drives the upper mold. The upper mold 4' is provided with four guide posts 41' and four punches. 42' and a movable thimble 43', the movable thimble 43' is set at the center of the upper mold 4', the four punches 42' form a quadrilateral around the movable thimble 43', the four The guide post 41' surrounds the movable thimble 43' and is located outside the punch 42'. The lower mold 3' is provided with a movable stopper mechanism 31', and the movable stopper mechanism 31' is located on the Below the punch 42', the movable stop mechanism 31' is used to fix the CQFJ product a, and make the punch 42' directly above the pin of the CQF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com