Gas shield clamping machine

A gas protection, clamping machine technology, applied in the direction of the chuck, the manipulator, the program control manipulator, etc., can solve the problems of high production and use cost, low work efficiency, insufficient safety, etc., and achieves low production cost, simple structure, easy to use. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

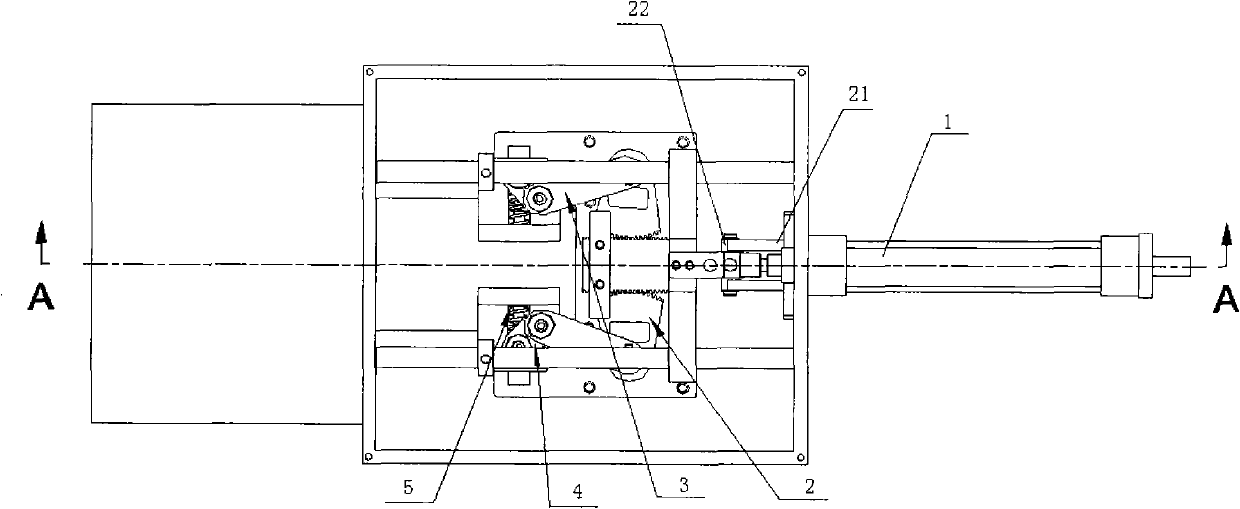

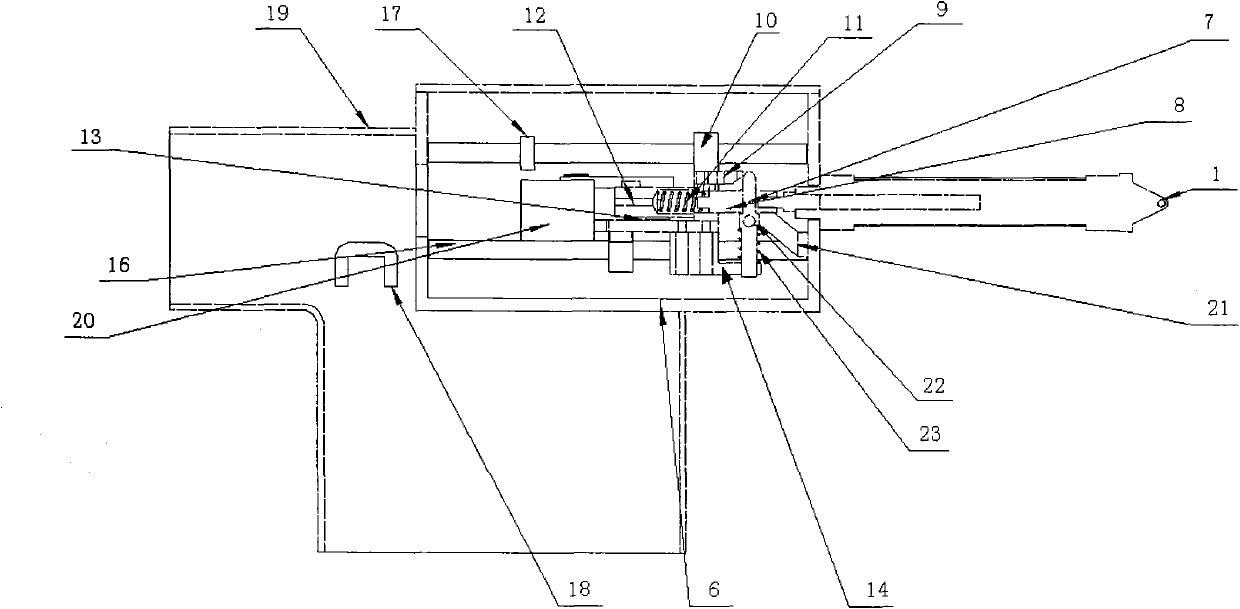

[0021] figure 1 It is a top view of an embodiment of the present invention; figure 2 for figure 1 A view from direction A.

[0022] Such as figure 1 and figure 2 Shown:

[0023] The gas-protected clamping machine includes a box body 6 with openings on the front and lower parts, a gripper 20 arranged in the box body 6, a sector gear 2, a rack 12, a rack seat 10, a flat plate 13, a joint 8, The hanging rod 7 and the cylinder 1 arranged at the rear of the box body, wherein the piston at the front of the cylinder 1 is connected to the joint 6, the through hole in the middle of the joint 6 is inserted with the hanging rod 7, and the hanging rod 7 located at the bottom of the joint 8 Also interspersed with a hanging rod shaft 22 in the through hole, the hanging rod shaft 22 cooperates with the positioning plate 21 arranged on the rear portion of the casing 6, and the top of the rack seat 10 is provided with a hanging plate 9 that matches the hanging rod 7, and the hanging Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com