Handheld sponge polishing wheel

A polishing wheel and sponge technology, applied in the field of polishing, can solve the problems of unstable shape, smaller contact area, inconvenient use, etc., and achieve the effect of improving grinding sharpness, increasing contact area, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

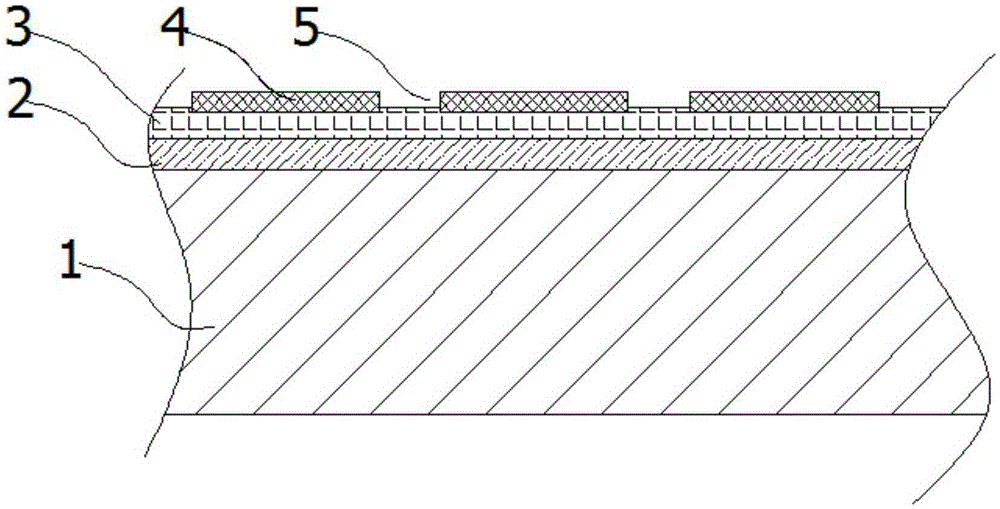

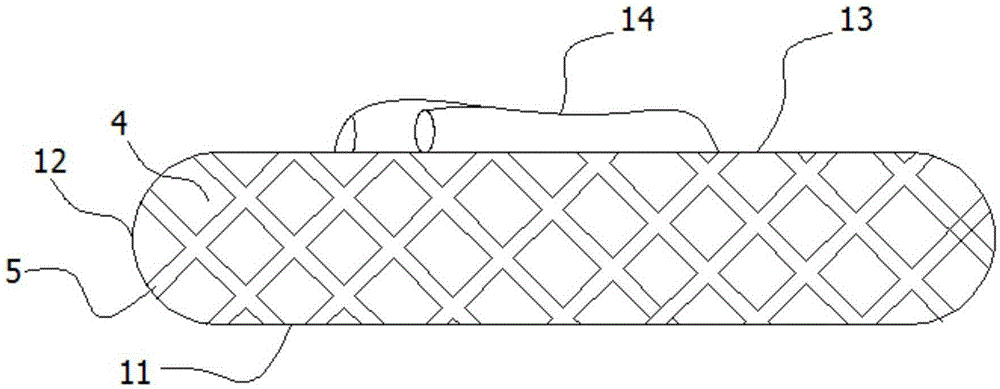

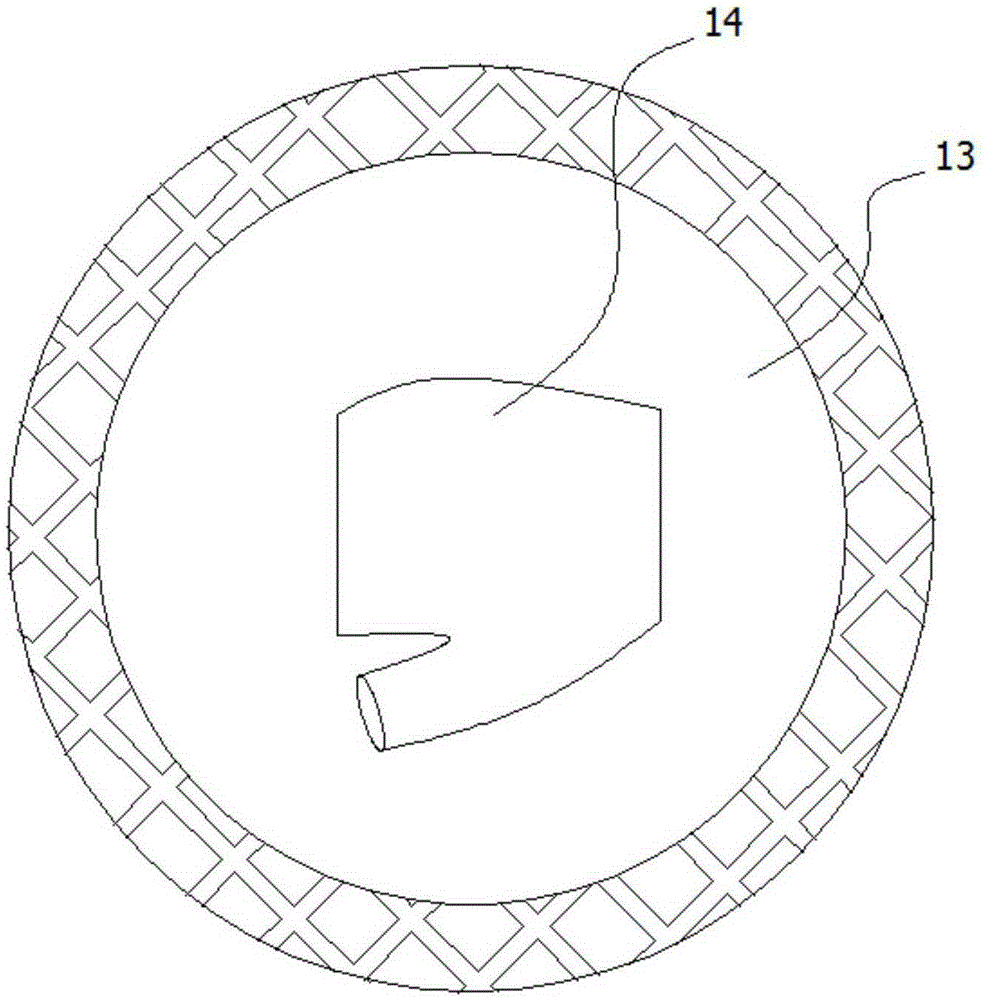

[0014] see figure 1 and Figure 4 , a kind of hand-held sponge polishing wheel of the present invention, comprises sponge matrix 1, and described sponge matrix 1 is divided into contact surface 11, side 12 and mounting surface 13, and contact surface 11 and side 12 are provided with film layer 2, and described film layer 2 The upper surface is provided with an abrasive glue mixture layer, and the abrasive glue mixture layer includes a glue layer 3 and an abrasive layer 4 , and the upper middle part of the abrasive layer 4 exposes the glue layer 3 .

[0015] The abrasive layer 4 is composed of regular geometric polishing blocks, grooves 5 are formed between the polishing blocks, and the depths of the grooves 5 are the same. The grooves 5 communicate with each other. The connected groove 5 can be used to form an air flow channel and a waste discharge channel, which can not only dissipate heat but also discharge the ground and polished powder.

[0016] The middle part of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com