Magnetic field isostatic pressing machine

An isostatic press, isostatic pressing technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of low orientation magnetic field, low degree of automation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

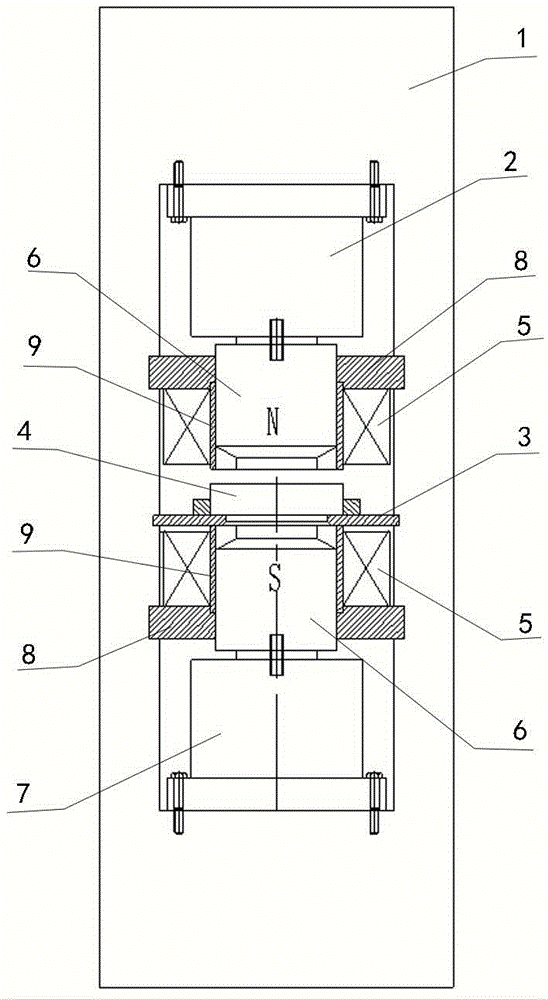

[0018] The magnetic field isostatic press includes a frame 1, which is a frame structure, an upper high-pressure oil cylinder 2 is arranged on the top surface of the inner frame of the frame 1, a workbench 3 is arranged in the middle of the frame, and an isostatic press is placed on the workbench. The mold 4 and the workbench 3 can reciprocate relative to the frame to realize the reciprocating shift position of the isostatic mold between the orientation pressing station directly below the upper high-pressure oil cylinder and the demoulding and feeding station outside the frame. The frame 1 is fixed with electromagnetic coils 5 of the same specifications located above the orientation press station of the isostatic pressing mold and below the workbench respectively. There is an iron core 6 inside the electromagnetic coil, and magnetic yoke plates 8 are horizontally fixed on both sides of the inner frame of the frame 1. , the upper end and the lower end of the electromagnetic coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com